Anaerobic means "living, active, occurring, or existing in the absence of free oxygen", as opposed to aerobic which means "living, active, or occurring only in the presence of oxygen." Anaerobic may also refer to:

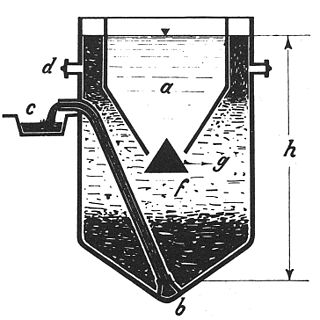

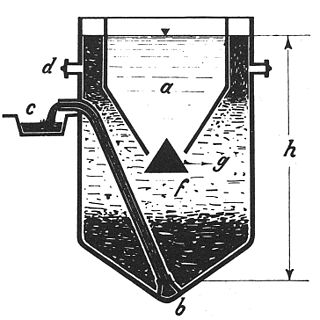

The Imhoff tank, named for German engineer Karl Imhoff (1876–1965), is a chamber suitable for the reception and processing of sewage. It may be used for the clarification of sewage by simple settling and sedimentation, along with anaerobic digestion of the extracted sludge. It consists of an upper chamber in which sedimentation takes place, from which collected solids slide down inclined bottom slopes to an entrance into a lower chamber in which the sludge is collected and digested. The two chambers are otherwise unconnected, with sewage flowing only through the upper sedimentation chamber and no flow of sewage in the lower digestion chamber. The lower chamber requires separate biogas vents and pipes for the removal of digested sludge, typically after 6-9 months of digestion. The Imhoff tank is in effect a two-story septic tank and retains the septic tank's simplicity while eliminating many of its drawbacks, which largely result from the mixing of fresh sewage and septic sludge in the same chamber.

A landfill site is a site for the disposal of waste materials by burial. Landfill is the oldest form of waste treatment, although the burial of the waste is modern; historically, refuse was simply left in piles or thrown into pits. Historically, landfills have been the most common method of organized waste disposal and remain so in many places around the world.

Waste stabilization ponds are ponds designed and built for wastewater treatment to reduce the organic content and remove pathogens from wastewater. They are man-made depressions confined by earthen structures. Wastewater or "influent" enters on one side of the waste stabilization pond and exits on the other side as "effluent", after spending several days in the pond, during which treatment processes take place.

Anaerobic digestion is a collection of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

Articles related to waste management include:

Upflow anaerobic sludge blanket (UASB) technology, normally referred to as UASB reactor, is a form of anaerobic digester that is used for wastewater treatment.

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter. The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Biodegradable waste includes any organic matter in waste which can be broken down into carbon dioxide, water, methane or simple organic molecules by micro-organisms and other living things by composting, aerobic digestion, anaerobic digestion or similar processes. In waste management, it also includes some inorganic materials which can be decomposed by bacteria. Such materials include gypsum and its products such as plasterboard and other simple organic sulfates which can decompose to yield hydrogen sulphide in anaerobic land-fill conditions.

An expanded granular sludge bed (EGSB) reactor is a variant of the upflow anaerobic sludge blanket digestion (UASB) concept for anaerobic wastewater treatment. The distinguishing feature is that a faster rate of upward-flow velocity is designed for the wastewater passing through the sludge bed. The increased flux permits partial expansion (fluidisation) of the granular sludge bed, improving wastewater-sludge contact as well as enhancing segregation of small inactive suspended particle from the sludge bed. The increased flow velocity is either accomplished by utilizing tall reactors, or by incorporating an effluent recycle. A scheme depicting the EGSB design concept is shown in this EGSB diagram.

The anaerobic clarigester is a form of anaerobic digester. It is regarded as being the ancestor of the upflow anaerobic sludge blanket digestion (UASB) anaerobic digester. A clarigester treats dilute biodegradable feedstocks and separates out solid and hydraulic (liquid) retention times. A diagram comparing the UASB, anaerobic clarigester and anaerobic contact processes can be found here.

The following is a partial list of types of anaerobic digesters. These processes and systems harness anaerobic digestion for purposes such as sewage treatment and biogas generation. Anaerobic digesters can be categorized according to two main criteria: by whether the biomass is fixed to a surface or can mix freely with the reactor liquid ; and by the organic loading rate. The widely used UASB reactor, for example, is a suspended-growth high-rate digester, with its biomass clumped into granules that will settle relatively easily and with typical loading rates in the range 5-10 kgCOD/m3/d.

In sewage treatment systems, an anaerobic filter (AF) is a form of anaerobic digester. The digestion tank contains a filter medium where anaerobic microbial populations—organisms that live in the absence of oxygen — can establish themselves. Such filters are commonly employed in the treatment of waste water. These reactors are gaining in popularity versus more established aerobic waste-water treatment systems because they produce a less solid residue than do other types of filter.

A hybrid biological reactor (HBR) was developed which involved the introduction of a new phase of attached-biomass into a regular suspended-growth system by addition of carriers to

An aerobic treatment system or ATS, often called (incorrectly) an aerobic septic system, is a small scale sewage treatment system similar to a septic tank system, but which uses an aerobic process for digestion rather than just the anaerobic process used in septic systems. These systems are commonly found in rural areas where public sewers are not available, and may be used for a single residence or for a small group of homes.

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous.

Dark fermentation is the fermentative conversion of organic substrate to biohydrogen. It is a complex process manifested by diverse groups of bacteria, involving a series of biochemical reactions using three steps similar to anaerobic conversion. Dark fermentation differs from photofermentation in that it proceeds without the presence of light.

Facultative lagoons are a type of waste stabilization pond used for biological treatment of industrial and domestic wastewater. Sewage or organic waste from food or fiber processing may be catabolized in a system of constructed ponds where adequate space is available to provide an average waste retention time exceeding a month. A series of ponds prevents mixing of untreated waste with treated wastewater and allows better control of waste residence time for uniform treatment efficiency.

The Jundiz recycling plant is located in the Basque Country, particularly in Vitoria-Gasteiz Jundiz Álava. This place is responsible for recycling the city garbage. The trash is converted by a physical-chemical or mechanical process to submit a substance or a product already used to a cycle of total or partial treatment for a commodity or a new product or raw materials from waste, introducing them back into life cycle. This occurs at the prospect of depletion of natural resources, macro economic and eliminate waste efficiently.