A ball differential is a type of differential typically used on radio-controlled cars. It differs from a geared differential by using several small ball bearings rotating between two plates, instead of bevel gears.

A ball differential is a type of differential typically used on radio-controlled cars. It differs from a geared differential by using several small ball bearings rotating between two plates, instead of bevel gears.

The first ball differential for Radio-controlled Cars was designed by Cecil Schumacher, a British motor sport engineer working at Cosworth and founder/owner of his eponymous model brand. Although a patent was applied for, it was denied as the idea had already been implemented into a lawn mower. Radio-controlled cars were still a new application for the ball differential and Schumacher is generally considered the modern day inventor of the concept. Such was the popularity of the ball differential, originally applied in 1/12 on-road cars, that he formed his eponymous company. [1]

To this date ball differentials remain very popular in the radio-controlled car market. They are used on almost every 1/12 on-road, scale touring car (although the sealed gear differential is gaining popularity in this class) and electric off-road produced by many manufacturers. In these classes they are regarded as the industry standard. Schumacher Racing Products even use ball differentials on their nitro truck range, these however use strong materials and larger and harder ball bearings.

Radio-controlled car manufacturers use the same basic design Schumacher created in the 1980s. The main part of the differential is a drive gear (or pulley in a belt transmission) with multiple holes cut through it, following its outside diameter. These holes are slightly larger than the width of the ball bearings, so that the balls, commonly around 2 mm diameter in a model car, sit inside the holes of the gear/pulley.

On either side of the gear are the thrust washers. The thrust washers are pushed against the ball bearings inside the gear by Belleville washers. On one side of the gear is an adjusting collar, which allows for adjustments in the amount of slip allowed by the differential. [2] A thrust bearing (or thrust race), on the opposite side of the gear, is used to stop the differential from loosening the retaining screw holding the output cups, used to attach the differential to the axle, onto the differential.

As the screw is tightened it pushes the Belleville and thrust washers onto the gear/pulley. This creates contact between the washers and ball bearings inside of the gear/pulley. The friction created by the contact between the washers and ball bearings is, aided by grease (commonly silicone grease), designed so that as one washer moves, the ball bearings rotate.

As the washer on one side of the gear rotates, the rotation of the balls causes the other washer to rotate in the opposite direction, because any rotating ball will have opposite sides moving in opposite directions .

Differential movement is achieved through the process of the thrust washers rotating with the ball bearings. The retaining screw is designed so the differential can be easily adjusted by tightening or loosening the screw, consequently changing force. This makes the differential more adjustable than geared differentials, but there is a lower limit since the drive is by friction so there is always some limited slip action.

There are several types of balls used in this type of differential. Some of the most common ball materials used by high end racers are ceramic and tungsten based. The advantage to something like ceramic based balls is that they are much harder, and have a longer life expectancy. Oftentimes when using less hard materials, the balls will "flat spot" causing a semi locked direction of the ball. This causes the differential to not turn with a smooth feeling and leaves it with an overall "gritty" feeling.

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

A differential is a gear train with three shafts that has the property that the rotational speed of one shaft is the average of the speeds of the others, or a fixed multiple of that average.

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

A continuously variable transmission (CVT), also known as a shiftless transmission, stepless transmission, pulley transmission, or, in case of motorcycles, a "twist-and-go", is an automatic transmission that can change seamlessly through a continuous range of effective gear ratios. This contrasts with other mechanical transmissions that offer a fixed number of gear ratios. The flexibility of a CVT with suitable control may allow the input shaft to maintain a constant angular velocity even as the output speed varies.

A rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two bearing rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

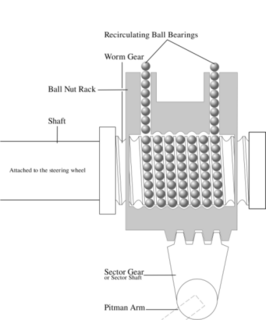

Recirculating ball, also known as recirculating ball and nut or worm and sector, is a steering mechanism commonly found in older automobiles, off-road vehicles, and some trucks. Most newer cars use the more economical rack and pinion steering instead, but some upmarket manufacturers held on to the design until well into the 1990s for the durability and strength inherent in the design. A few, including Chrysler, General Motors and Lada, still use this technology in certain models including the Jeep Wrangler and the Lada Niva.

The headset is the set of components on a bicycle that provides a rotatable interface between the bicycle fork and the head tube of a bicycle frame. The tube through which the steerer of the fork passes is called the head tube. A typical headset consists of two cups that are pressed into the top and bottom of the headtube. Inside the two cups are bearings which provide a low friction contact between the bearing cup and the steerer.

Bolted joints are one of the most common elements in construction and machine design. They consist of fasteners that capture and join other parts, and are secured with the mating of screw threads.

A thrust bearing is a particular type of rotary bearing. Like other bearings they permit rotation between parts, but they are designed to support a predominantly axial load.

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

A set screw, also known as a blind screw or a grub screw, is a type of screw generally used to secure an object within or against another object, usually without using a nut. The most common examples are securing a pulley or gear to a shaft. Set screws are usually headless, meaning that the screw is fully threaded and has no head projecting past the thread's major diameter. If a set screw does have a head, the thread will extend all the way to the head. A set screw is almost always driven with an internal-wrenching drive, such as a hex socket (Allen), star (Torx), square socket (Robertson), or a slot. The set screw passes through a threaded hole in the outer object and is tightened against the inner object to prevent it from moving relative to the outer object. It exerts compressional or clamping force through the bottom tip that projects through the hole.

A jackscrew, or screw jack, is a type of jack that is operated by turning a leadscrew. It is commonly used to lift moderately heavy weights, such as vehicles; to raise and lower the horizontal stabilizers of aircraft; and as adjustable supports for heavy loads, such as the foundations of houses.

A worm drive is a gear arrangement in which a worm meshes with a worm gear. The two elements are also called the worm screw and worm wheel. The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional leadscrews, ballscrews tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls.

The Remington Arms Model 241 Speedmaster, an autoloading rimfire rifle, was manufactured from 1935 to 1951 from a John Browning design. Remington reports that 107,345 rifles were manufactured in .22 Short or .22 Long Rifle. A similar rifle is currently being sold by Browning Arms Company.

Brinelling is the permanent indentation of a hard surface. It is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force, and the depth and diameter of the mark indicates the Brinell hardness of the surface. Brinelling is a process of wear in which similar marks are pressed into the surface of a moving part, such as bearings or hydraulic pistons. The brinelling is usually undesirable, as the parts often mate with other parts in very close proximity. The very small indentations can quickly lead to improper operation, such as chattering or excess vibration, which in turn can accelerate other forms of wear, such as spalling and galling.

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction, a slight stretching of the bolt, and compression of the parts to be held together.

A roller screw, also known as a planetary roller screw or satellite roller screw, is a low-friction precision screw-type actuator, a mechanical device for converting rotational motion to linear motion, or vice versa. Planetary roller screws are used as the actuating mechanism in many electro-mechanical linear actuators. Due to its complexity the roller screw is a relatively expensive actuator, but may be suitable for high-precision, high-speed, heavy-load, long-life and heavy-use applications.