Related Research Articles

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it back and forth, or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power source. An abrasive saw has a powered circular blade designed to cut through metal or ceramic.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut.

A block plane is a small metal-bodied woodworking hand plane which typically has the blade bedded at a lower angle than other planes, with the bevel up. It is designed to cut end grain and do touchup or finish work. It is typically small enough to be used with one hand.

A smoothing plane or smooth plane is a type of bench plane used in woodworking. The smoothing plane is typically the last plane used on a wood surface, removing very fine shavings to leave a smooth finish. When used effectively it quickly produces a finish that equals or surpasses that made by sandpaper.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces.

A card scraper or cabinet scraper is a woodworking shaping and finishing tool. It is used to manually remove small amounts of material and excels in tricky grain areas where hand planes would cause tear out. Card scrapers are most suitable for working with hardwoods, and can be used instead of sandpaper. Scraping produces a cleaner surface than sanding; it does not clog the pores of the wood with dust, and does not leave a fuzz of torn fibers.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versality of the jack plane has led to it being the most common bench plane in use. The name jack plane is sometimes used interchangeably with the longer fore plane.

Japanese carpentry was developed more than a millennium ago through Chinese architectural influences from the 12th century. It is a form of ancient Chinese wooden architecture and woodworking joints that involves building wooden furniture without the use of nails, screws, glue, or electric tools.

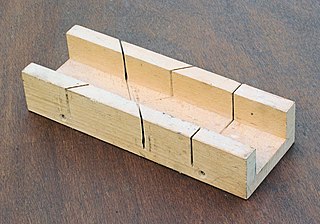

A mitre box or miter box is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

Sharpening is the process of creating or refining the edge joining two non-coplanar faces into a converging apex, thereby creating an edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness.

Although an antique tool might be said to be one that is more than a hundred years old, the term is often used to describe any old tool of quality that might be deemed collectable.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A slater, or slate mason, is a tradesperson who covers buildings with slate.

A surform tool features perforated sheet metal and resembles a food grater. A surform tool consists of a steel strip with holes punched out and the rim of each hole sharpened to form a cutting edge. The strip is mounted in a carriage or handle. Surform tools were called "cheese graters" decades before they entered the market as kitchen utensils used to grate cheese. Surform planes have been described as a cross between a rasp and a plane.

Chip formation is part of the process of cutting materials by mechanical means, using tools such as saws, lathes and milling cutters.

The firm of T. Norris & Son was one of the most prestigious makers of hand tools in England in the late nineteenth and early twentieth centuries and famed for the quality and gracefulness of its output, notably of its metal planes. Both wooden and metal planes made in Norris's workshop survive as do other edge tools. Some Norris planes, especially bespoke models, are highly prized by woodworkers and collectors.

References

- 1 2 3 4 5 6 Taunton's Complete Illustrated Guide to Using Woodworking Tools, by Lonnie Bird, Taunton Press, 2004, ISBN 1-56158-597-1 pp. 127-129