Joinery is a part of woodworking that involves joining pieces of wood or lumber, to produce more complex items. Some wood joints employ fasteners, bindings, or adhesives, while others use only wood elements. The characteristics of wooden joints - strength, flexibility, toughness, appearance, etc. - derive from the properties of the materials involved and the purpose of the joint. Therefore, different joinery techniques are used to meet differing requirements. For example, the joinery used to construct a house can be different from that used to make puzzle toys, although some concepts overlap. In British English usage it is distinguished from carpentry which relates to structural timber work.

Carpentry is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. Carpenters traditionally worked with natural wood and did rougher work such as framing, but today many other materials are also used and sometimes the finer trades of cabinetmaking and furniture building are considered carpentry. In the United States, 98.5% of carpenters are male, and it was the fourth most male-dominated occupation in the country in 1999. In 2006 in the United States, there were about 1.5 million carpentry positions. Carpenters are usually the first tradesmen on a job and the last to leave. Carpenters normally framed post-and-beam buildings until the end of the 19th century; now this old-fashioned carpentry is called timber framing. Carpenters learn this trade by being employed through an apprenticeship training—normally 4 years—and qualify by successfully completing that country's competence test in places such as the United Kingdom, the United States, Canada, Switzerland, Australia and South Africa. It is also common that the skill can be learned by gaining work experience other than a formal training program, which may be the case in many places.

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, in flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface. Before plywood became common, tongue and groove boards were also used for sheathing buildings and to construct concrete formwork.

A joiner is an artisan and tradesperson who builds things by joining pieces of wood, particularly lighter and more ornamental work than that done by a carpenter, including furniture and the "fittings" of a house, ship, etc. Joiners may work in a workshop, because the formation of various joints is made easier by the use of non-portable, powered machinery, or on job site. A joiner usually produces items such as interior and exterior doors, windows, stairs, tables, bookshelves, cabinets, furniture, etc. In shipbuilding a marine joiner may work with materials other than wood such as linoleum, fiberglass, hardware, and gaskets.

A smoothing plane or smooth plane is a type of bench plane used in woodworking. The smoothing plane is typically the last plane used on a wood surface, removing very fine shavings to leave a smooth finish. When used effectively it quickly produces a finish that equals or surpasses that made by sandpaper.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A try square or try-square is a woodworking tool used for marking and checking 90° angles on pieces of wood. Though woodworkers use many different types of square, the try square is considered one of the essential tools for woodworking.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

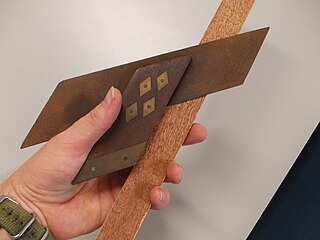

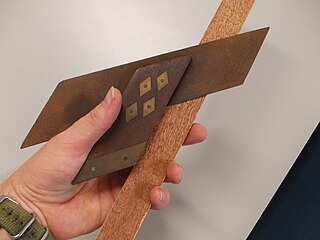

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces.

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versality of the jack plane has led to it being the most common bench plane in use. The name jack plane is sometimes used interchangeably with the longer fore plane.

Japanese carpentry was developed more than a millennium ago through Chinese architectural influences such as Ancient Chinese wooden architecture and uses woodworking joints. It involves building wooden furniture without the use of nails, screws, glue or electric tools.

The term planer may refer to several types of carpentry tools, woodworking machines or metalworking machine tools.

A holdfast or hold fast is a form of temporary clamp used to hold a workpiece firmly to the top or side of a wooden workbench or the top of an anvil.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The Shaker Shed is an exhibit building at Shelburne Museum in Shelburne, Vermont. It exhibits the museum's collection of hand-tools and household equipment.

A burnisher is a hand tool used in woodworking for creating a burr on a card scraper.

The fore plane is a type of woodworking bench plane typically used for preparing and flattening rough workpieces before using other planes, such as the jointer plane and the smoothing plane. The name fore plane is sometimes used synonymously with the jack plane, but the fore plane is usually longer in length, making it more effective at levelling larger workpieces.

A square is a tool used for marking and referencing a 90° angle, though mitre squares are used for 45° angles. Squares see common use in woodworking, metalworking, construction and technical drawing. Some squares incorporate a scale for measuring distances or for calculating angles.

A miter square or mitre square is a hand tool used in woodworking and metalworking for marking and checking angles other than 90°. Most miter squares are for marking and checking 45° angles and its supplementary angle, 135°.