In woodworking and carpentry, hand saws, also known as "panel saws", are used to cut pieces of wood into different shapes. This is usually done in order to join the pieces together and carve a wooden object. They usually operate by having a series of sharp points of some substance that is harder than the wood being cut. The hand saw is a bit like a tenon saw, but with one flat, sharp edge.

An adze is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes have been used since the Stone Age. They are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze —a short-handled tool swung with one hand—and the foot adze (hoe)—a long-handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. A similar tool is called a mattock, which differs by having two blades, one perpendicular to the handle and one parallel.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power source. An abrasive saw has a powered circular blade designed to cut through metal or ceramic.

Wood carving is a form of woodworking by means of a cutting tool (knife) in one hand or a chisel by two hands or with one hand on a chisel and one hand on a mallet, resulting in a wooden figure or figurine, or in the sculptural ornamentation of a wooden object. The phrase may also refer to the finished product, from individual sculptures to hand-worked mouldings composing part of a tracery.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut.

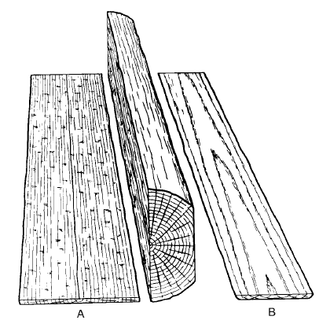

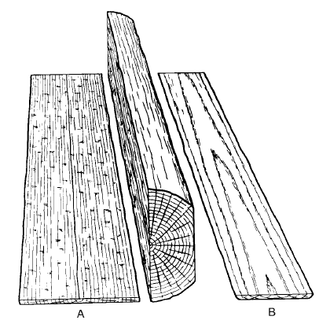

In woodworking, a rip-cut is a type of cut that severs or divides a piece of wood parallel to the grain. The other typical type of cut is a cross-cut, a cut perpendicular to the grain. Unlike cross-cutting, which shears the wood fibers, a rip saw works more like a series of chisels, lifting off small splinters of wood. The nature of the wood grain requires the shape of the saw teeth to be different thus the need for both rip saws and crosscut saws; however some circular saw blades are combination blades and can make both types of cuts. A rip cut is the fundamental type of cut made at a sawmill.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.

A try square or try-square is a woodworking tool used for marking and checking 90° angles on pieces of wood. Though woodworkers use many different types of square, the try square is considered one of the essential tools for woodworking.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

A drawknife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer than it is deep. It is pulled or "drawn" toward the user.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials.

A backsaw is any hand saw which has a stiffening rib on the edge opposite the cutting edge, enabling better control and more precise cutting than with other types of saws. Backsaws are normally used in woodworking for precise work, such as cutting dovetails, mitres, or tenons in cabinetry and joinery. Because of the stiffening rib, backsaws are limited in the depth to which they can cut. Backsaws usually have relatively closely spaced teeth, often with little or no set.

Japanese carpentry was developed more than a millennium ago through Chinese architectural influences from the 12th century. It is a form of ancient Chinese wooden architecture and woodworking joints that involves building wooden furniture without the use of nails, screws, glue, or electric tools.

A scroll saw is a small electric or pedal-operated saw used to cut intricate curves in wood, metal, or other materials. The fineness of its blade allows it to cut more delicately than a power jigsaw, and more easily than a hand coping saw or fretsaw. Like those tools, it is capable of creating curves with edges, by pivoting its table.

A jointer or in some configurations, a jointer-planer is a woodworking machine used to produce a flat surface along a board's length. As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels. A planer-jointer setup has the width that enables smoothing ('surface planing') and leveling the faces (widths) of boards small enough to fit the tables.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A surform tool features perforated sheet metal and resembles a food grater. A surform tool consists of a steel strip with holes punched out and the rim of each hole sharpened to form a cutting edge. The strip is mounted in a carriage or handle. Surform tools were called "cheese graters" decades before they entered the market as kitchen utensils used to grate cheese. Surform planes have been described as a cross between a rasp and a plane.