An adze or adz is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes have been used since the Stone Age. They are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze —a short-handled tool swung with one hand—and the foot adze (hoe)—a long-handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. A similar tool is called a mattock, which differs by having two blades, one perpendicular to the handle and one parallel.

A broadaxe is a large broad-headed axe. There are two categories of cutting edge on broadaxes, both are used for shaping logs into beams by hewing. On one type, one side is flat, and the other side beveled, a basilled edge, also called a side axe, single bevel, or chisle-edged axe. On the other type, both sides are beveled, sometimes called a double bevel axe, which produces a scalloped cut.

A chisel is a wedged hand tool with a characteristically shaped cutting edge on the end of its blade, for carving or cutting a hard material. The tool can be used by hand, struck with a mallet, or applied with mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

A block plane is a small metal-bodied woodworking hand plane which typically has the blade bedded at a lower angle than other planes, with the bevel up. It is designed to cut end grain and do touchup or finish work. It is typically small enough to be used with one hand.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A combination square is a multi-purpose measuring and marking tool used in metalworking, woodworking, and stonemasonry. It is composed of a rule and one or more interchangeable heads that can be attached to the rule. Other names for the tool include adjustable square, combo square, and sliding square.

A try square or try-square is a woodworking tool used for marking and checking 90° angles on pieces of wood. Though woodworkers use many different types of square, the try square is considered one of the essential tools for woodworking.

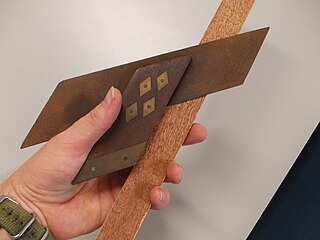

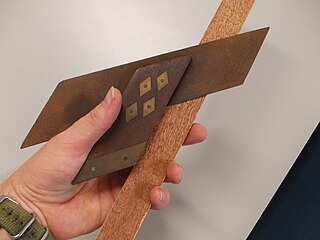

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, a spokeshave is not suited to working large surfaces.

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versatility of the jack plane has led to it being the most common bench plane in use. The name jack plane is sometimes used interchangeably with the longer fore plane.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

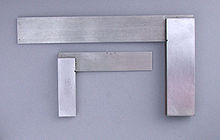

A machinist square or engineer's square is the metalworkers' equivalent of a try square. It consists of a steel blade inserted and either welded or pinned into a heavier body at an angle of 90°. Usually a small notch is present at the inside corner of the square. This prevents small particles from accumulating at the juncture and affecting the square's reading.

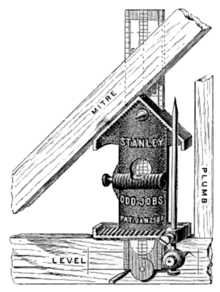

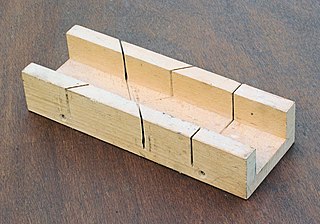

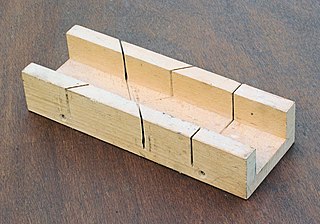

A mitre box or miter box is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

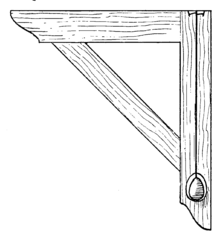

A bench hook is a workbench appliance used in woodworking to hold a workpiece in place while crosscutting with a hand saw. A bench hook is a simple method used to improve accuracy and safety.

A marking knife or striking knife is a woodworking layout tool used for accurately marking workpieces. It is used to cut a visible line, which can then be used to guide a hand saw, chisel or plane when making woodworking joints and other operations. They are generally used when marking across the grain of the wood, with scratch awls better suited for marking with the grain.

A woodworking float, also called a planemaker's float, is a tapered, flat, single cut file of two types: edge float and the flat sided float which are traditional woodworking tools generally used when making a wooden plane. The float is used to cut, flatten, and smooth key areas of wood by abrasion. Despite the name its woodworking uses go well beyond planemaking.

A fence is a part of many woodworking tools; it is typically used to guide or secure a workpiece while it is being sawn, planed, routed or marked. Fences play an important role for both accuracy and safety. Fences are usually straight and vertical, and made from metal, wood or plastic.

The Warrington hammer,joiners' hammer, English pattern hammer, or Warrington pattern hammer is a kind of cross-peen hammer used in woodworking. The chisel-like cross-peen side is used to set small nails and pins while the smaller, rounded face is used to finish driving them in. The cross-peen side of the tool is also used for refining work, such as furniture and cabinet making. While the standard claw hammer is used for tasks that involve greater use of force, the Warrington hammer is preferred for projects that require precision. A standard Warrington hammer is commonly around 12+1⁄2 inches (320 mm) in length with the hammer head weighing between 10 and 14 ounces.

A burnisher is a hand tool used in woodworking for creating a burr on a card scraper.

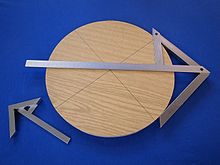

A miter square or mitre square is a hand tool used in woodworking and metalworking for marking and checking angles other than 90°. Most miter squares are for marking and checking 45° angles and its supplementary angle, 135°.