A circular saw or a buzz saw, is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

In woodworking and carpentry, hand saws, also known as "panel saws", are used to cut pieces of wood into different shapes. This is usually done in order to join the pieces together and carve a wooden object. They usually operate by having a series of sharp points of some substance that is harder than the wood being cut. The hand saw is a bit like a tenon saw, but with one flat, sharp edge.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end; for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historically, humans have made blades from flaking stones such as flint or obsidian, and from various metal such as copper, bronze, and iron. Modern blades are often made of steel or ceramic. Blades are one of humanity's oldest tools, and continue to be used for combat, food preparation, and other purposes.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

A razor is a bladed tool primarily used in the removal of body hair through the act of shaving. Kinds of razors include straight razors, safety razors, disposable razors, and electric razors.

A safety razor is a shaving implement with a protective device positioned between the edge of the blade and the skin. The initial purpose of these protective devices was to reduce the level of skill needed for injury-free shaving, thereby reducing the reliance on professional barbers.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal, and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

A hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials.

A straight razor is a razor with a blade that can fold into its handle. They are also called open razors and cut-throat razors. The predecessors of the modern straight razors include bronze razors, with cutting edges and fixed handles, produced by craftsmen from Ancient Egypt during the New Kingdom. Solid gold and copper razors were also found in Ancient Egyptian tombs dating back to the 4th millennium BC.

Japanese carpentry was carpentry in Japan developed more than a millennium ago. It is a form of woodworking joints that involves building wooden furniture without the use of nails, screws, glue, or electric tools.

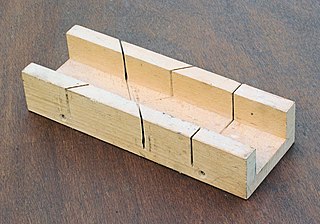

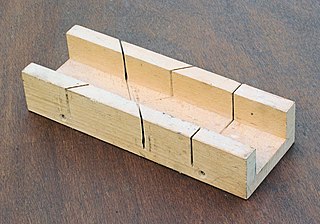

A mitre box or miter box is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

Sharpening is the process of creating or refining the edge joining two non-coplanar faces into a converging apex, thereby creating an edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness.

Knife sharpening is the process of making a knife or similar tool sharp by grinding against a hard, rough surface, typically a stone, or a flexible surface with hard particles, such as sandpaper. Additionally, a leather razor strop, or strop, is often used to straighten and polish an edge.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The saw chain, or cutting chain, is a key component of a chainsaw. It consists of steel links held together by rivets, and superficially resembles the bicycle-style roller chain, although it is closer in design to a leaf chain. Its key differences are sharp cutting teeth on the outside of the chain loop, and flat drive links on the inside, to retain the chain on the saw's bar and allow propulsion by the engine or motor.