Related Research Articles

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes, to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements.

In woodworking and carpentry, hand saws, also known as "panel saws", are used to cut pieces of wood into different shapes. This is usually done in order to join the pieces together and carve a wooden object. They usually operate by having a series of sharp points of some substance that is harder than the wood being cut. The hand saw is a bit like a tenon saw, but with one flat, sharp edge.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end; for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

Wood carving is a form of woodworking by means of a cutting tool (knife) in one hand or a chisel by two hands or with one hand on a chisel and one hand on a mallet, resulting in a wooden figure or figurine, or in the sculptural ornamentation of a wooden object. The phrase may also refer to the finished product, from individual sculptures to hand-worked mouldings composing part of a tracery.

In woodworking, a rip-cut is a type of cut that severs or divides a piece of wood parallel to the grain. The other typical type of cut is a cross-cut, a cut perpendicular to the grain. Unlike cross-cutting, which shears the wood fibers, a rip saw works more like a series of chisels, lifting off small splinters of wood. The nature of the wood grain requires the shape of the saw teeth to be different thus the need for both rip saws and crosscut saws; however some circular saw blades are combination blades and can make both types of cuts. A rip cut is the fundamental type of cut made at a sawmill.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

A ripsaw is a wood saw that is specially designed for making a rip cut, a cut made parallel to the direction of the wood grain.

A drawknife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer than it is deep. It is pulled or "drawn" toward the user.

A mortiser or morticer is a specialized woodworking machine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint.

A backsaw is any hand saw which has a stiffening rib on the edge opposite the cutting edge, enabling better control and more precise cutting than with other types of saws. Backsaws are normally used in woodworking for precise work, such as cutting dovetails, mitres, or tenons in cabinetry and joinery. Because of the stiffening rib, backsaws are limited in the depth to which they can cut. Backsaws usually have relatively closely spaced teeth, often with little or no set.

A mitre joint is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint.

Frame and panel construction, also called rail and stile, is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques used in making a slab solid wood cabinet door or drawer front, the door is constructed of several solid wood pieces running in a vertical or horizontal direction with exposed endgrains. Usually, the panel is not glued to the frame but is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame.

Japanese carpentry was carpentry in Japan developed more than a millennium ago through Chinese architectural influences from the 12th century. It is a form of ancient Chinese wooden architecture and woodworking joints that involves building wooden furniture without the use of nails, screws, glue, or electric tools.

A butt joint is a wood joint in which the end of a piece of material is simply placed against another piece. The butt joint is the simplest joint. An unreinforced butt joint is also the weakest joint, as it provides a limited surface area for gluing and lacks any mechanical interlocking to resist external forces.

In joinery, a groove is a slot or trench cut into a member which runs parallel to the grain. A groove is thus differentiated from a dado, which runs across the grain.

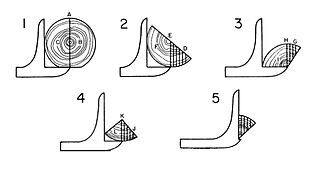

Quarter sawing or quartersawing is a woodworking process that produces quarter-sawn or quarter-cut boards in the rip cutting of logs into lumber. The resulting lumber can also be called radially-sawn or simply quartered. There is widespread confusion between the terms rift sawn and quarter sawn with the terms defined both with opposite meanings and as synonyms.