Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes, to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements.

A chisel is a wedged hand tool with a characteristically shaped cutting edge on the end of its blade, for carving or cutting a hard material. The tool can be used by hand, struck with a mallet, or applied with mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

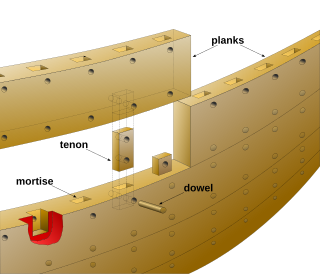

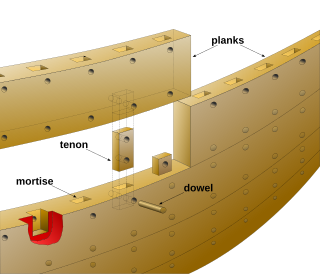

A mortiseand tenon joint connects two pieces of wood or other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A lap joint or overlap joint is a joint in which the members overlap. Lap joints can be used to join wood, plastic, or metal. A lap joint can be used in woodworking for joining wood together.

A joist is a horizontal structural member used in framing to span an open space, often between beams that subsequently transfer loads to vertical members. When incorporated into a floor framing system, joists serve to provide stiffness to the subfloor sheathing, allowing it to function as a horizontal diaphragm. Joists are often doubled or tripled, placed side by side, where conditions warrant, such as where wall partitions require support.

A snake skeleton consists primarily of the skull, vertebrae, and ribs, with only vestigial remnants of the limbs.

Door furniture or door hardware refers to any of the items that are attached to a door or a drawer to enhance its functionality or appearance.

A treenail, also trenail, trennel, or trunnel, is a wooden peg, pin, or dowel used to fasten pieces of wood together, especially in timber frames, covered bridges, wooden shipbuilding and boat building. It is driven into a hole bored through two pieces of structural wood.

A mortiser or morticer is a specialized woodworking machine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint.

Frame and panel construction, also called rail and stile, is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques used in making a slab solid wood cabinet door or drawer front, the door is constructed of several solid wood pieces running in a vertical or horizontal direction with exposed endgrains. Usually, the panel is not glued to the frame but is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame.

A butt joint is a wood joint in which the end of a piece of material is simply placed against another piece. The butt joint is the simplest joint. An unreinforced butt joint is also the weakest joint, as it provides a limited surface area for gluing and lacks any mechanical interlocking to resist external forces.

The Domino is a loose mortise and tenon joining tool manufactured by the German company Festool.

Pocket-hole joinery, or pocket-screw joinery, involves drilling a hole at an angle — usually 15 degrees — into one work piece, and then joining it to a second work piece with a self-tapping screw.

A bridle joint is a woodworking joint, similar to a mortise and tenon, in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The distinguishing feature is that the tenon and the mortise are cut to the full width of the tenon member.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A twybil is a hand tool used for green woodworking. It is used for chopping out mortises when timber framing, or making smaller pieces such as gates. It combines chopping and levering functions in a single tool.

Ancient furniture was made from many different materials, including reeds, wood, stone, metals, straws, and ivory. It could also be decorated in many different ways. Sometimes furniture would be covered with upholstery, upholstery being padding, springs, webbing, and leather. Features which would mark the top of furniture, called finials, were common. To decorate furniture, contrasting pieces would be inserted into depressions in the furniture. This practice is called inlaying.

A hex key is a simple driver for bolts or screws that have heads with internal hexagonal recesses (sockets).

Phoenician joints is a locked mortise and tenon wood joinery technique used in shipbuilding to fasten watercraft hulls. The locked mortise and tenon technique consists of cutting a mortise, or socket, into the edges of two planks and fastening them together with a rectangular wooden knob. The assembly is then locked in place by driving a dowel through one or more holes drilled through the mortise side wall and tenon.