A knife is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone, over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin.

A chisel is a wedged hand tool with a characteristically shaped cutting edge on the end of its blade, for carving or cutting a hard material. The tool can be used by hand, struck with a mallet, or applied with mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

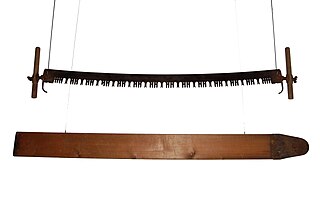

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, a spokeshave is not suited to working large surfaces.

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as "the mysteries of the turners' guild." The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe.

A crosscut saw is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool.

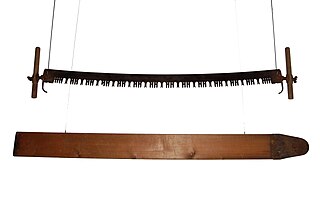

A froe, shake axe or paling knife is a tool for cleaving wood by splitting it along the grain. It is an L-shaped tool, used by hammering one edge of its blade into the end of a piece of wood in the direction of the grain, then twisting the blade in the wood by rotating the haft (handle).

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives — notably a large chef's knife and a smaller serrated blade utility knife — there are also many specialized knives that are designed for specific tasks such as a tough cleaver, a small paring knife, and a bread knife. Kitchen knives can be made from several different materials, though the commonest is a hardened steel blade with a wooden handle.

A straight razor is a razor with a blade that can fold into its handle. They are also called open razors and cut-throat razors. The predecessors of the modern straight razors include bronze razors, with cutting edges and fixed handles, produced by craftsmen from Ancient Egypt during the New Kingdom. Solid gold and copper razors were also found in Ancient Egyptian tombs dating back to the 4th millennium BC.

Japanese carpentry was developed more than a millennium ago that is known for its ability to create everything from temples to houses to tea houses to furniture by wood with the use of few nails.

A marking knife or striking knife is a woodworking layout tool used for accurately marking workpieces. It is used to cut a visible line, which can then be used to guide a hand saw, chisel or plane when making woodworking joints and other operations. They are generally used when marking across the grain of the wood, with scratch awls better suited for marking with the grain.

The Woodwright's Shop was an American traditional woodworking show hosted by master carpenter Roy Underhill and airing on television network PBS. It is one of the longest running how-to shows on PBS, with 36 13-episode seasons produced. The show debuted as a local program in 1979, and the show went national in 1980. It is filmed at the UNC-TV studios in Research Triangle Park, North Carolina. It is no longer being produced.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The crooked knife sometimes referred to as a "curved knife", "carving knife," or "mocotaugan," from the Cree term "môhkotâkan," is a woodworking knife, typically with a curved end. The crooked knife is a common tool found amongst the native Americans of the Eastern Woodlands as well as non-native woodworkers. The crooked in "crooked knife" refers to its unusual shape with the handle set at an oblique angle to the blade. The blade can be straight or curved, long or short and can be made of a steel forged specifically for the knife, or from reused hardened steel from another source. The shape of the blade, whether curved or straight, is a function of the carving purpose of the user: straight for whittling wood, making splints for baskets and incising, curved for hollowing out bowls and masks and ladles, as well as myriad other usages.

A surform tool features perforated sheet metal and resembles a food grater. A surform tool consists of a steel strip with holes punched out and the rim of each hole sharpened to form a cutting edge. The strip is mounted in a carriage or handle. Surform tools were called "cheese graters" decades before they entered the market as kitchen utensils used to grate cheese. Surform planes have been described as a cross between a rasp and a plane.

An axe is an implement that has been used for millennia to shape, split, and cut wood, to harvest timber, as a weapon, and as a ceremonial or heraldic symbol. The axe has many forms and specialised uses but generally consists of an axe head with a handle, also called a haft or a helve.

A shaving horse is a combination of vice and workbench, used for green woodworking. Typical usage of the shaving horse is to create a round profile along a square piece, such as for a chair leg or to prepare a workpiece for the pole lathe. They are used in crafts such as coopering and bowyery.

A twybil is a hand tool used for green woodworking. It is used for chopping out mortises when timber framing, or making smaller pieces such as gates. It combines chopping and levering functions in a single tool.