Woodworking is the skill of making items from wood, and includes cabinet making, wood carving, joinery, carpentry, and woodturning.

A smoothing plane or smooth plane is a type of bench plane used in woodworking. The smoothing plane is typically the last plane used on a wood surface, removing very fine shavings to leave a smooth finish. When used effectively it quickly produces a finish that equals or surpasses that made by sandpaper.

The jointer plane, also known as the try plane or trying plane, is a type of hand plane used in woodworking to straighten the edges of boards in the process known as jointing, and to flatten the faces of larger boards. Its long length is designed to 'ride over' the undulations of an uneven surface, skimming off the peaks, gradually creating a flatter surface. In thicknessing or preparing rough stock, the jointer plane is usually preceded by the fore plane or jack plane and followed by the smoothing plane.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A try square or try-square is a woodworking tool used for marking and checking 90° angles on pieces of wood. Though woodworkers use many different types of square, the try square is considered one of the essential tools for woodworking.

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces.

A card scraper or cabinet scraper is a woodworking shaping and finishing tool. It is used to manually remove small amounts of material and excels in tricky grain areas where hand planes would cause tear out. Card scrapers are most suitable for working with hardwoods, and can be used instead of sandpaper. Scraping produces a cleaner surface than sanding; it does not clog the pores of the wood with dust, and does not leave a fuzz of torn fibers.

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versality of the jack plane has led to it being the most common bench plane in use. The name jack plane is sometimes used interchangeably with the longer fore plane.

Japanese carpentry was developed more than a millennium ago through Chinese architectural influences from the 12th century. It is a form of ancient Chinese wooden architecture and woodworking joints that involves building wooden furniture without the use of nails, screws, glue, or electric tools.

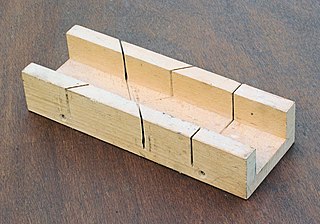

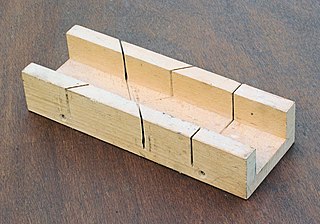

A mitre box or miter box is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

A bench hook is a workbench appliance used in woodworking to hold a workpiece in place while crosscutting with a hand saw. A bench hook is a simple method used to improve accuracy and safety.

A marking knife or striking knife is a woodworking layout tool used for accurately marking workpieces. It is used to cut a visible line, which can then be used to guide a hand saw, chisel or plane when making woodworking joints and other operations. They are generally used when marking across the grain of the wood, with scratch awls better suited for marking with the grain.

The Woodwright's Shop is an American traditional woodworking show hosted by master carpenter Roy Underhill and airing on television network PBS. It is one of the longest running how-to shows on PBS, with thirty-five 13-episode seasons produced. Since its debut in 1979, the show has aired over 400 episodes. The first two seasons were broadcast only on public TV in North Carolina; the season numbering was restarted when the show went national in 1981. It is filmed at the UNC-TV studios in Research Triangle Park, North Carolina.

A holdfast or hold fast is a form of temporary clamp used to hold a workpiece firmly to the top or side of a wooden workbench or the top of an anvil.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A surform tool features perforated sheet metal and resembles a food grater. A surform tool consists of a steel strip with holes punched out and the rim of each hole sharpened to form a cutting edge. The strip is mounted in a carriage or handle. Surform tools were called "cheese graters" decades before they entered the market as kitchen utensils used to grate cheese. Surform planes have been described as a cross between a rasp and a plane.

A fence is a part of many woodworking tools, they are typically used to guide or secure a workpiece while it is being sawn, planed, routed or marked. Fences play an important role for both accuracy and safety. Fences are usually straight and vertical, and made from metal, wood or plastic.

A razee plane is a style of wooden hand plane which has a section of its rear cut away, so that the plane has a lower handle. This design makes the plane lighter, with a lower centre of mass, and puts the handle closer to the workpiece and cutting edge – giving the user greater control.

A square is a tool used for marking and referencing a 90° angle, though mitre squares are used for 45° angles. Squares see common use in woodworking, metalworking, construction and technical drawing. Some squares incorporate a scale for measuring distances or for calculating angles.