A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver chuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use.

A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel clamp or a surgical clamp.

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewelry.

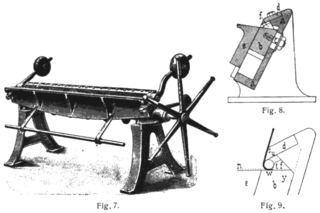

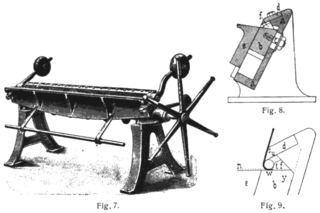

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. It is also known as a bending machine or bending brake or in Britain as a sheet metal folder or just a folder.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic. Band saw is recommended for use in cutting metal as it produces much less toxic fumes and particulates when compared with angle grinder and reciprocating saw.

A Weaver rail mount is a system to connect telescopic sights and other accessories to firearms and certain crossbows. It uses a pair of parallel rails and several slots perpendicular to these rails.

A hose clamp (hose clip,hose lock or Jubilee Clip (UK)) is a device used to attach and seal a hose onto a fitting such as a barb or nipple.

A collet is a segmented sleeve, band or collar. One of the two radial surfaces of a collet is usually tapered and the other is cylindrical. The term collet commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool, but collets have other mechanical applications.

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece.

A tap wrench is a hand tool used to turn taps or other small tools, such as hand reamers and screw extractors.

A vise or vice is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. The jaws are often flat but may have grooves, adapt to the shape of the workpiece or be custom made.

A C-clamp or G-clamp or G-cramp is a type of clamp device typically used to hold a wood or metal workpiece, and often used in, but are not limited to, carpentry and welding. Often believed that these clamps are called "C" clamps because of their C-shaped frame, or also often called C-clamps or G-clamps because including the screw part, they are shaped like an uppercase letter G. However, in fact, they were originally called a carriage maker's clamp, or Carriage Clamp.

A pipe clamp is a type of clamp often employed in woodworking, piping or cabinet shops. When referring to woodwork or cabinet shops, pipe clamps are usually composed of commercially manufactured clamp heads or "jaws" and a length of common threaded pipe. The capacity of the clamp is determined by the length of the pipe used. When referring to piping, pipe clamps are used to connect the pipe to the pipe hanger assembly.

A bicycle saddle, sometimes called a bicycle seat, is one of five contact points on an upright bicycle, the others being the two pedals and the two handles on the handlebars. The bicycle saddle has been known as such since the bicycle evolved from the draisine, a forerunner of the bicycle. It performs a similar role as a horse's saddle, not bearing all the weight of the rider as the other contact points also take some of the load.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

In stagecraft, a c-clamp can refer to a number of different pieces of hardware, depending on its intended use.

The shaft collar is a simple, yet important, machine component found in many power transmission applications, most notably motors and gearboxes. The collars are used as mechanical stops, locating components, and bearing faces. The simple design lends itself to easy installation.

An ironworker is a tradesman who works in the iron-working industry. Ironworkers assemble the structural framework in accordance with engineered drawings and install the metal support pieces for new buildings. They also repair and renovate old structures using reinforced concrete and steel. Ironworkers may work on factories, steel mills, and utility plants.

A boring bar is a tool used in metalworking and woodworking. Boring is a technique used in many aspects of building. Woodworkers have used boring as a form of drilling for centuries. In woodworking, the boring tool is static in size and used to form circular plunge cuts. In metalworking, boring is slightly different in that the hole that results need not be circular. In metal boring the tool can be plunged and dragged on the X or Y axes to create a slot or asymmetrical hole or channel, or it may be moved only in an up-and-down motion to create a perfect circular hole.