Standardization or standardisation is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organizations and governments. Standardization can help maximize compatibility, interoperability, safety, repeatability, or quality. It can also facilitate a normalization of formerly custom processes. In social sciences, including economics, the idea of standardization is close to the solution for a coordination problem, a situation in which all parties can realize mutual gains, but only by making mutually consistent decisions.

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known accuracy, a device generating the quantity to be measured such as a voltage, a sound tone, or a physical artifact, such as a meter ruler.

A ruler, sometimes called a rule, scale or a line gauge, is an instrument used to make length measurements, whereby a user estimates a length by reading from a series of markings called "rules" along an edge of the device. Commonly the instrument is rigid and the edge itself is a straightedge, which additionally allows one to draw straight lines. Some rulers, such as cloth or paper tape measures, are non-rigid. Specialty rulers exist that have flexible edges that retain a chosen shape; these find use in sewing, arts, and crafts.

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair. A die is used to cut or form the male portion of the mating pair. The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading.

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with an indicating scale, or an internal mechanism which will indicate when a specified (adjustable) torque value has been reached during application.

The Unified Thread Standard (UTS) defines a standard thread form and series—along with allowances, tolerances, and designations—for screw threads commonly used in the United States and Canada. It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread were chosen as an inch fraction rather than a millimeter value. The UTS is currently controlled by ASME/ANSI in the United States.

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: tension joints and shear joints.

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener.

Caliper(s) or calliper(s) are an instrument used to measure the dimensions of an object; namely, the diameter or depth of a hole. The least count of vernier caliper is 0.1 mm.

A radius gauge, also known as a fillet gauge, is a tool used to measure the radius of an object.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

A bore gauge is a collective term for the tools that are unique to the process of accurately measuring holes.

A go/no-go gauge refers to an inspection tool used to check a workpiece against its allowed tolerances via a go/no-go test. Its name is derived from two tests: the check involves the workpiece having to pass one test (go) and fail the other (no-go).

A rangefinder is a device used to measure distances to remote objects. Originally optical devices used in surveying, they soon found applications in other fields, such as photography, the military, and space travel. They were especially useful for finding the range of a target, such as in naval gunnery and anti-aircraft artillery. The word telemeter is derived from Ancient Greek τῆλε (têle) 'distant, far away', and μέτρον (métron) 'something used to measure'.

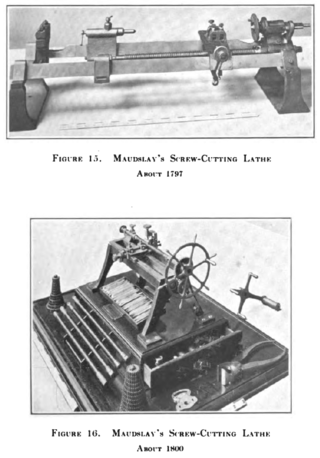

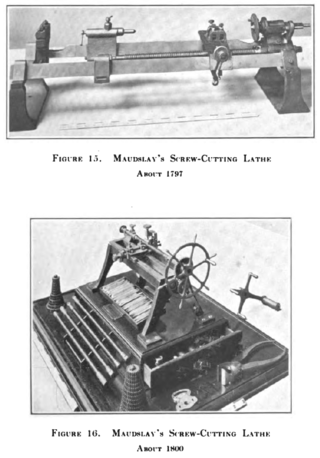

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch.

A screw and a bolt are similar types of fastener typically made of metal and characterized by a helical ridge, called a male thread.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

A drawbar force gauge is a gauge designed to measure forces on a machine tool's drawbar. These types of machines are found in metalworking, woodworking, stone cutting, and carbon fiber fabricating shops. Many modern machines generate well in excess of 50,000 N (12,000 lbf). Measuring and maintaining this force is an important and necessary part of a machine shop preventative maintenance plan.

Length measurement, distance measurement, or range measurement (ranging) refers to the many ways in which length, distance, or range can be measured. The most commonly used approaches are the rulers, followed by transit-time methods and the interferometer methods based upon the speed of light.