A sextant is a doubly reflecting navigation instrument that measures the angular distance between two visible objects. The primary use of a sextant is to measure the angle between an astronomical object and the horizon for the purposes of celestial navigation.

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

Significant figures, also referred to as significant digits or sig figs, are specific digits within a number written in positional notation that carry both reliability and necessity in conveying a particular quantity. When presenting the outcome of a measurement, if the number of digits exceeds what the measurement instrument can resolve, only the number of digits within the resolution's capability are dependable and therefore considered significant.

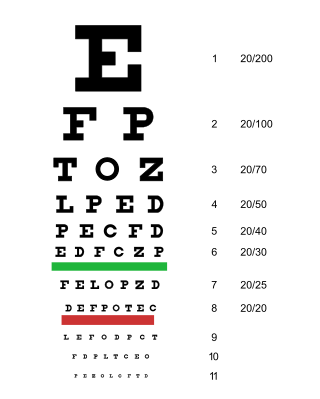

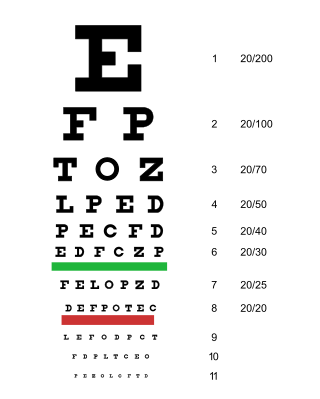

Visual acuity (VA) commonly refers to the clarity of vision, but technically rates an animal's ability to recognize small details with precision. Visual acuity depends on optical and neural factors. Optical factors of the eye influence the sharpness of an image on its retina. Neural factors include the health and functioning of the retina, of the neural pathways to the brain, and of the interpretative faculty of the brain.

Pierre Vernier was a French mathematician and instrument inventor. He was the inventor and eponym of the vernier scale used in measuring devices.

A goniometer is an instrument that either measures an angle or allows an object to be rotated to a precise angular position. The term goniometry derives from two Greek words, γωνία (gōnía) 'angle' and μέτρον (métron) 'measure'. The protractor is a commonly used type in the fields of mechanics, engineering, and geometry.

Caliper(s) or calliper(s) are an instrument used to measure the dimensions of an object; namely, the diameter or depth of a hole. The word caliper comes from latin roots meaning precise pincer.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

A bore gauge is a collective term for the tools that are unique to the process of accurately measuring holes.

A linear encoder is a sensor, transducer or readhead paired with a scale that encodes position. The sensor reads the scale in order to convert the encoded position into an analog or digital signal, which can then be decoded into position by a digital readout (DRO) or motion controller.

A thousandth of an inch is a derived unit of length in a system of units using inches. Equal to 1⁄1000 of an inch, a thousandth is commonly called a thou or, particularly in North America, a mil.

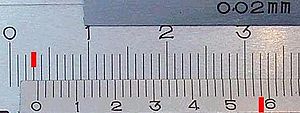

In the science of measurement, the least count of a measuring instrument is the smallest value in the measured quantity that can be resolved on the instrument's scale. The least count is related to the precision of an instrument; an instrument that can measure smaller changes in a value relative to another instrument, has a smaller "least count" value and so is more precise. Any measurement made by the instrument can be considered repeatable to no less than the resolution of the least count. The least count of an instrument is inversely proportional to the precision of the instrument.

Diameter at breast height, or DBH, is a standard method of expressing the diameter of the trunk or bole of a standing tree. DBH is one of the most common dendrometric measurements.

A level staff, also called levelling rod, is a graduated wooden or aluminium rod, used with a levelling instrument to determine the difference in height between points or heights of points above a vertical datum. When used for stadiametric rangefinding, the level staff is called a stadia rod.

A dividing engine is a device employed to mark graduations on measuring instruments.

Transversals are a geometric construction on a scientific instrument to allow a graduation to be read to a finer degree of accuracy. Their use creates what is sometimes called a diagonal scale, an engineering measuring instrument which is composed of a set of parallel straight lines which are obliquely crossed by another set of straight lines. Diagonal scales are used to measure small fractions of the unit of measurement.

Reflecting instruments are those that use mirrors to enhance their ability to make measurements. In particular, the use of mirrors permits one to observe two objects simultaneously while measuring the angular distance between the objects. While reflecting instruments are used in many professions, they are primarily associated with celestial navigation as the need to solve navigation problems, in particular the problem of the longitude, was the primary motivation in their development.

An Elton's quadrant is a derivative of the Davis quadrant. It adds an index arm and artificial horizon to the instrument, and was invented by English sea captain John Elton, who patented his design in 1728 and published details of the instrument in the Philosophical Transactions of the Royal Society in 1732.

Nonius is a measuring tool used in navigation and astronomy named in honour of its inventor, Pedro Nunes, a Portuguese author, mathematician and navigator. The nonius was created in 1542 as a system for taking finer measurements on circular instruments such as the astrolabe. The system was eventually adapted into the Vernier scale in 1631 by the French mathematician Pierre Vernier.

A Philadelphia rod is a level staff used in surveying. The rod is used in levelling procedures to determine elevations and is read using a level.