A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing and to transform many other materials.

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning.

Smoking is the process of flavoring, browning, cooking, or preserving food by exposing it to smoke from burning or smoldering material, most often wood. Meat, fish, and lapsang souchong tea are often smoked.

A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction is

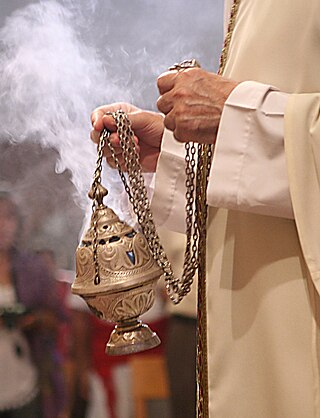

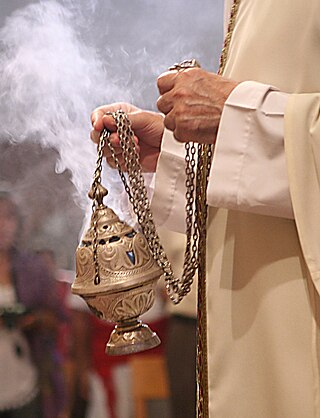

A censer, incense burner, perfume burner or pastille burner is a vessel made for burning incense or perfume in some solid form. They vary greatly in size, form, and material of construction, and have been in use since ancient times throughout the world. They may consist of simple earthenware bowls or fire pots to intricately carved silver or gold vessels, small table top objects a few centimetres tall to as many as several metres high. Many designs use openwork to allow a flow of air. In many cultures, burning incense has spiritual and religious connotations, and this influences the design and decoration of the censer.

Hardwood is wood from angiosperm trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood contrasts with softwood.

Pulpwood can be defined as timber that is ground and processed into a fibrous pulp. It is a versatile natural resource commonly used for paper-making but also made into low-grade wood and used for chips, energy, pellets, and engineered products.

A stove or range is a device that generates heat inside or on top of the device, for local heating or cooking. Stoves can be powered with many fuels, such as electricity, natural gas, gasoline, wood, and coal.

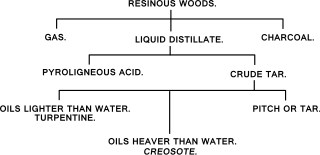

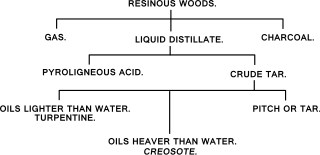

Dry distillation is the heating of solid materials to produce gaseous products. The method may involve pyrolysis or thermolysis, or it may not.

Fire making, fire lighting or fire craft is the process of artificially starting a fire. It requires completing the fire triangle, usually by heating tinder above its autoignition temperature.

A chimenea or chiminea(US English) is a freestanding front-loading fireplace or oven with a bulbous body and usually a vertical smoke vent or chimney.

Wood drying reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as kiln-dried timber or lumber, whereas air drying is the more traditional method.

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox.

Leather crafting or simply leathercraft is the practice of making leather into craft objects or works of art, using shaping techniques, coloring techniques or both.

A wood-burning stove is a heating or cooking appliance capable of burning wood fuel, often called solid fuel, and wood-derived biomass fuel, such as sawdust bricks. Generally the appliance consists of a solid metal closed firebox, often lined by fire brick, and one or more air controls. The first wood-burning stove was patented in Strasbourg in 1557. This was two centuries before the Industrial Revolution, so iron was still prohibitively expensive. The first wood-burning stoves were high-end consumer items and only gradually became used widely.

Wood ash is the powdery residue remaining after the combustion of wood, such as burning wood in a fireplace, bonfire, or an industrial power plant. It is largely composed of calcium compounds along with other non-combustible trace elements present in the wood. It has been used for many purposes throughout history.

Charcoal is a lightweight black carbon residue produced by strongly heating wood in minimal oxygen to remove all water and volatile constituents. In the traditional version of this pyrolysis process, called charcoal burning, often by forming a charcoal kiln, the heat is supplied by burning part of the starting material itself, with a limited supply of oxygen. The material can also be heated in a closed retort. Modern charcoal briquettes used for outdoor cooking may contain many other additives, e.g. coal.

Pellet heating is a heating system in which wood pellets are combusted. Other pelletized fuels such as straw pellets are used occasionally. Today's central heating system which run on wood pellets as a renewable energy source are comparable in operation and maintenance of oil and gas heating systems.

A pellet boiler is a heating system that burns wood pellets. Pellet boilers are used in central heating systems for heat requirements from 3.9 kW (kilowatt) to 1 MW (megawatt) or more. Pellet central heating systems are used in single family homes, and in larger residential, commercial, or institutional applications. Pellet boiler systems run most efficiently at full load and can usually be regulated down to 30% of full load. Since the warm up phase of pellet boilers usually takes longer than for oil or gas firing systems, short burning phases have negative effects on the fuel efficiency. In order to improve energy efficiency and reduce harmful emissions, pellet boilers are usually combined with buffer systems, such as insulated water tanks.

The conservation and restoration of wooden artifacts refers to the preservation of art and artifacts made of wood. Conservation and restoration in regards to cultural heritage is completed by a conservator-restorer.