A tobacco pipe, often called simply a pipe, is a device specifically made to smoke tobacco. It comprises a chamber for the tobacco from which a thin hollow stem (shank) emerges, ending in a mouthpiece. Pipes can range from very simple machine-made briar models to highly prized hand-made artisanal implements made by renowned pipemakers, which are often very expensive collector's items.

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools.

A drain cleaner, also known as drainopener, refers to a person, device, or product used to unblock sewer pipes or clear clogged wastewater drains. This term typically applies to chemical, enzymatic, or mechanical tools such as commercial chemical cleaners, plumber’s snakes, drain augers, bio-enzyme solutions, or toilet plungers. In some contexts, it may also refer to a plumber or professional who specializes in drain cleaning and maintenance.

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled.

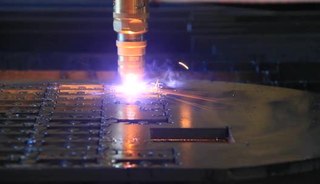

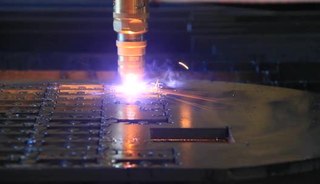

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials.

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial computer numerical control (CNC) applications down to small hobbyist shops.

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined, the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have compression rings, called ferrules or olives, in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives.

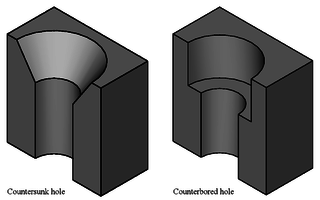

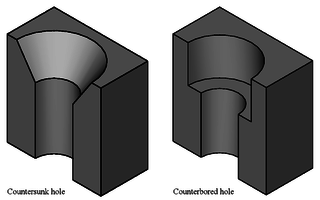

In manufacturing, a countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material. A countersink may also be used to remove the burr left from a drilling or tapping operation, thereby improving the finish of the product and removing any hazardous sharp edges.

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations. They remove material by their movement within the machine or directly from the cutter's shape.

Burrs or burs are small cutting tools; not to be confused with small pieces of metal formed from cutting metal, used in die grinders, rotary tools, or dental drills. The name may be considered appropriate when their small-sized head is compared to a bur or their teeth are compared to a metal burr.

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. They can have several end configurations: round (ball), tapered, or straight are a few popular types. They are most commonly used in "milling machines" that move a piece of material against the end mill to remove chips of the material to create a desired size or shape. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. Not all mills can cut axially; those designed to cut axially are known as end mills.

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs.

Snips, also known as shears, are hand tools used to cut sheet metal and other tough webs. It is a cutting tool. Workers use various types of snips, with the cutting edges being straight or curved to various degrees. The style of edge employed will depend if a straight sheer or some type of shapes cut is necessary. There are two broad categories: tinner's snips, which are similar to common scissors, and compound-action snips, which use a compound leverage handle system to increase the mechanical advantage.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

Oxy-fuel welding torch and oxy-fuel cutting are processes that use fuel gases and oxygen to weld or cut metals. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903. Pure oxygen, instead of air, is used to increase the flame temperature to allow localized melting of the workpiece material in a room environment.

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to some other process: such as bending a corner in sheet or joining two tubes at a tee joint, notching one to fit closely to the other.

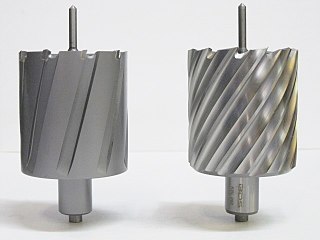

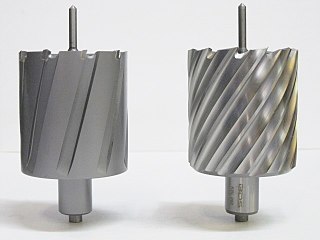

An annular cutter is a form of core drill used to create holes in metal. An annular cutter, named after the annulus shape, cuts only a groove at the periphery of the hole and leaves a solid core or slug at the center.