A knife is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone, over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it.

The Swiss Army knife is a multi-tool pocketknife manufactured by Victorinox. The term "Swiss Army knife" was coined by American soldiers after World War II after they had trouble pronouncing the German word "Offiziersmesser", meaning "officer’s knife".

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historically, humans have made blades from flaking stones such as flint or obsidian, and from various metal such as copper, bronze and iron. Modern blades are often made of steel or ceramic. Blades are one of humanity's oldest tools, and continue to be used for combat, food preparation, and other purposes.

A Japanese kitchen knife is a type of a knife used for food preparation. These knives come in many different varieties and are often made using traditional Japanese blacksmithing techniques. They can be made from stainless steel, or hagane, which is the same kind of steel used to make Japanese swords. Most knives are referred to as hōchō or the variation -bōchō in compound words but can have other names including -kiri. There are four general categories used to distinguish the Japanese knife designs: handle, blade grind, steel, and construction.

A blade's grind is its cross-sectional shape in a plane normal to the edge. Grind differs from blade profile, which is the blade's cross-sectional shape in the plane containing the blade's edge and the centre contour of the blade's back. The grind of a blade should not be confused with the bevel forming the sharpened edge; it more usually describes the overall cross-section of the blade, not inclusive of the beveled cutting edge which is typically of a different, less acute angle as the bevel ground onto the blade to give it a cross-sectional shape. For example, the famous Buck 110 hunting knife has a "hollow ground" blade, with concave blade faces, but the cutting edge itself is a simple, flat-ground bevel of lesser angle. It would be difficult, if not impossible, to put a "hollow grind" onto the actual cutting edge of the blade itself, which is a very narrow and small bevel.

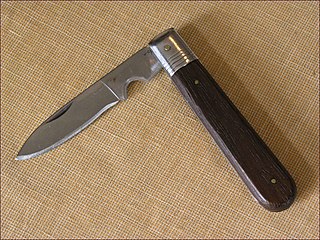

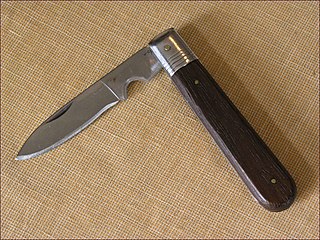

Penknife, or pen knife, is a British English term for a small folding knife. Today the word penknife is the common British English term for both a pocketknife, which can have single or multiple blades, and for multi-tools, with additional tools incorporated into the design.

A razor strop is a flexible strip of leather, canvas, denim fabric, balsa wood, or other soft material, used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool such as a chisel. In many cases stropping re-aligns parts of the blade edge that have been bent out of alignment. In other cases, especially when abrasive polishing compound is used, stropping may remove a small amount of metal. Stropping can also burnish the blade.

A drawknife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer than it is deep. It is pulled or "drawn" toward the user.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials.

In cooking, a chef's knife, also known as a cook's knife, is a cutting tool used in food preparation. The chef's knife was originally designed primarily to slice and disjoint large cuts of beef. Today it is the primary general-utility knife for most western cooks.

Japanese carpentry was developed more than a millennium ago through Chinese architectural influences such as Ancient Chinese wooden architecture and uses woodworking joints. It involves building wooden furniture without the use of nails, screws, glue or electric tools.

Sharpening stones, or whetstones, are used to sharpen the edges of steel tools and implements, such as knives, scissors, scythes, razors, chisels, hand scrapers, and plane blades, through grinding and honing.

A scratch awl is a woodworking layout and point-making tool. It is used to scribe a line to be followed by a hand saw or chisel when making woodworking joints and other operations.

Sharpening is the process of creating or refining 2 perpendicular axis into a converging "Apex" creating an edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness.

Scary sharp is a method of sharpening woodworking tools with sandpaper instead of conventional methods of oilstone or waterstone sharpening. The sandpaper referred to here can be any abrasive impregnated sheet used in the various industries to smooth surfaces and examples include glass paper, silicon carbide, emery cloth, etc. The sandpaper is affixed to another hard, flat substrate to create the sharpening surface. Sheet-glass is commonly used, but a machinist's granite surfacing block, marble baking slabs, plywood, medium-density fibreboard (MDF) or even jointer out-feed tables will produce satisfactory results. The method of fixation is usually a matter of the user's preference, and can include plain water, sprayed-on adhesive, or by simply using adhesive-backed abrasive paper. This is exactly the same method as that used by materials scientists in preparing polished samples for metallography.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

Paul Sellers is a British woodworker, writer and teacher. He was apprenticed as a woodworker in the UK in 1965 at the age of 15. He moved to the US in 1984 and quickly became noted for his ability in traditional woodworking. He has and continues to teach people the craft of woodworking. He taught at the Homestead Heritage Woodworking School in Texas. During his time at the School he designed, and made with a team of craftspeople, cabinets for the White House. He started the New Legacy School of Woodworking that provides short courses. Sellers is author of Working Wood which was published in 2011 and Essential Woodworking Hand Tools which was published in 2016. He then moved to premises at the Sylva Wood Centre in Long Wittenham, near Abingdon in Oxfordshire. Recently Sellers moved to larger premises in an industrial unit in Abingdon, Oxfordshire.

A twybil is a hand tool used for green woodworking. It is used for chopping out mortises when timber framing, or making smaller pieces such as gates. It combines chopping and levering functions in a single tool.