Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and allow them to cool, causing fusion. Common alternative methods include solvent welding using chemicals to melt materials being bonded without heat, and solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding.

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the tool or electrode, while the other is called the workpiece-electrode, or work piece. The process depends upon the tool and work piece not making physical contact. Extremely hard materials like carbides, ceramics, titanium alloys and heat treated tool steels that are very difficult to machine using conventional machining can be precisely machined by EDM.

Spot welding is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current.

Shielded metal arc welding (SMAW), also known as manual metal arc welding, flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld.

A corona discharge is an electrical discharge caused by the ionization of a fluid such as air surrounding a conductor carrying a high voltage. It represents a local region where the air has undergone electrical breakdown and become conductive, allowing charge to continuously leak off the conductor into the air. A corona discharge occurs at locations where the strength of the electric field around a conductor exceeds the dielectric strength of the air. It is often seen as a bluish glow in the air adjacent to pointed metal conductors carrying high voltages, and emits light by the same mechanism as a gas discharge lamp (Chemiluminescence). Corona discharges can also happen in weather, such as thunderstorms, where objects like ship masts or airplane wings have a charge significantly different from the air around them.

A flashtube (flashlamp) is an electric arc lamp designed to produce extremely intense, incoherent, full-spectrum white light for a very short time. A flashtube is a glass tube with an electrode at each end and is filled with a gas that, when triggered, ionizes and conducts a high-voltage pulse to make light. Flashtubes are used most in photography; they also are used in science, medicine, industry, and entertainment.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

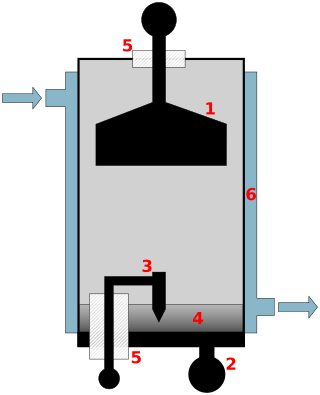

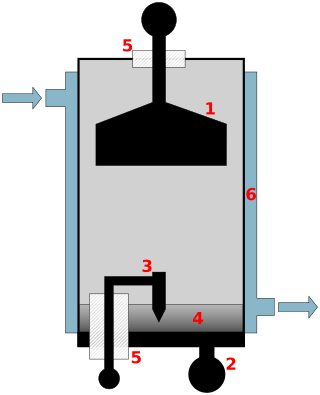

An ignitron is a type of gas-filled tube used as a controlled rectifier and dating from the 1930s. Invented by Joseph Slepian while employed by Westinghouse, Westinghouse was the original manufacturer and owned trademark rights to the name "Ignitron". Ignitrons are closely related to mercury-arc valves but differ in the way the arc is ignited. They function similarly to thyratrons; a triggering pulse to the igniter electrode turns the device "on", allowing a high current to flow between the cathode and anode electrodes. After it is turned on, the current through the anode must be reduced to zero to restore the device to its nonconducting state. They are used to switch high currents in heavy industrial applications.

Electron-beam welding (EBW) is a fusion welding process in which a beam of high-velocity electrons is applied to two materials to be joined. The workpieces melt and flow together as the kinetic energy of the electrons is transformed into heat upon impact. EBW is often performed under vacuum conditions to prevent dissipation of the electron beam.

In electronics, electrical breakdown or dielectric breakdown is a process that occurs when an electrically insulating material, subjected to a high enough voltage, suddenly becomes a conductor and current flows through it. All insulating materials undergo breakdown when the electric field caused by an applied voltage exceeds the material's dielectric strength. The voltage at which a given insulating object becomes conductive is called its breakdown voltage and, in addition to its dielectric strength, depends on its size and shape, and the location on the object at which the voltage is applied. Under sufficient voltage, electrical breakdown can occur within solids, liquids, or gases. However, the specific breakdown mechanisms are different for each kind of dielectric medium.

Stud welding is a technique similar to flash welding where a fastener or specially formed nut is welded onto another metal part, typically a base metal or substrate. The fastener can take different forms, but typically fall under threaded, unthreaded, or tapped. The bolts may be automatically fed into the stud welder. Weld nuts generally have a flange with small nubs that melt to form the weld. Weld studs are used in stud welding systems. Manufacturers create weld studs for the two main forms of stud welding: capacitor discharge stud welding and drawn arc stud welding

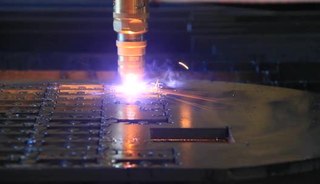

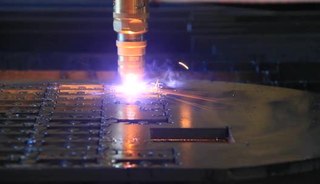

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial computer numerical control (CNC) applications down to small hobbyist shops.

An electric arc is an electrical breakdown of a gas that produces a prolonged electrical discharge. The current through a normally nonconductive medium such as air produces a plasma, which may produce visible light. An arc discharge is initiated either by thermionic emission or by field emission. After initiation, the arc relies on thermionic emission of electrons from the electrodes supporting the arc. An arc discharge is characterized by a lower voltage than a glow discharge. An archaic term is voltaic arc, as used in the phrase "voltaic arc lamp".

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc.

Gas tungsten arc welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas. A filler metal is normally used, though some welds, known as 'autogenous welds', or 'fusion welds' do not require it. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

Electric resistance welding (ERW) is a welding process in which metal parts in contact are permanently joined by heating them with an electric current, melting the metal at the joint. Electric resistance welding is widely used, for example, in manufacture of steel pipe and in assembly of bodies for automobiles. The electric current can be supplied to electrodes that also apply clamping pressure, or may be induced by an external magnetic field. The electric resistance welding process can be further classified by the geometry of the weld and the method of applying pressure to the joint: spot welding, seam welding, flash welding, projection welding, for example. Some factors influencing heat or welding temperatures are the proportions of the workpieces, the metal coating or the lack of coating, the electrode materials, electrode geometry, electrode pressing force, electric current and length of welding time. Small pools of molten metal are formed at the point of most electrical resistance as an electric current is passed through the metal. In general, resistance welding methods are efficient and cause little pollution, but their applications are limited to relatively thin materials.

In metalworking, a filler metal is a metal added in the making of a joint through welding, brazing, or soldering.

Plasma activation is a method of surface modification employing plasma processing, which improves surface adhesion properties of many materials including metals, glass, ceramics, a broad range of polymers and textiles and even natural materials such as wood and seeds. Plasma functionalization also refers to the introduction of functional groups on the surface of exposed materials. It is widely used in industrial processes to prepare surfaces for bonding, gluing, coating and painting. Plasma processing achieves this effect through a combination of reduction of metal oxides, ultra-fine surface cleaning from organic contaminants, modification of the surface topography and deposition of functional chemical groups. Importantly, the plasma activation can be performed at atmospheric pressure using air or typical industrial gases including hydrogen, nitrogen and oxygen. Thus, the surface functionalization is achieved without expensive vacuum equipment or wet chemistry, which positively affects its costs, safety and environmental impact. Fast processing speeds further facilitate numerous industrial applications.

A supercapacitor (SC), also called an ultracapacitor, is a high-capacity capacitor, with a capacitance value much higher than solid-state capacitors but with lower voltage limits. It bridges the gap between electrolytic capacitors and rechargeable batteries. It typically stores 10 to 100 times more energy per unit volume or mass than electrolytic capacitors, can accept and deliver charge much faster than batteries, and tolerates many more charge and discharge cycles than rechargeable batteries.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination.