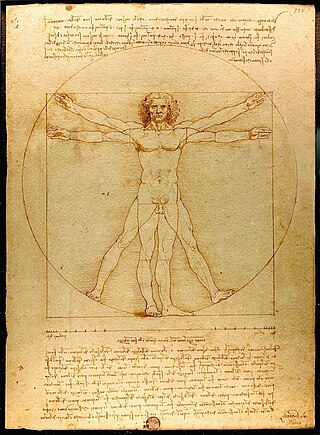

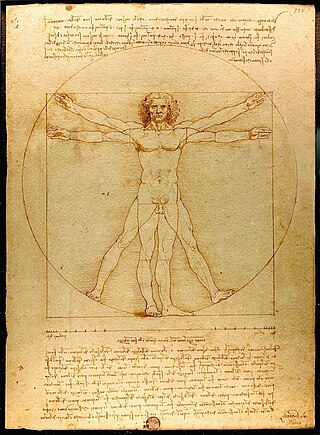

Drawing is a visual art that uses an instrument to mark paper or another two-dimensional surface. The instruments used to make a drawing are pencils, crayons, pens with inks, brushes with paints, or combinations of these, and in more modern times, computer styluses with graphics tablets or gamepads in VR drawing software.

Technical drawing, drafting or drawing, is the act and discipline of composing drawings that visually communicate how something functions or is constructed.

An engineering drawing is a type of technical drawing that is used to convey information about an object. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Usually, a number of drawings are necessary to completely specify even a simple component. These drawings are linked together by a "master drawing." This "master drawing" is more commonly known as an assembly drawing. The assembly drawing gives the drawing numbers of the subsequent detailed components, quantities required, construction materials and possibly 3D images that can be used to locate individual items. Although mostly consisting of pictographic representations, abbreviations and symbols are used for brevity and additional textual explanations may also be provided to convey the necessary information.

Stationery refers to commercially manufactured writing materials, including cut paper, envelopes, writing implements, continuous form paper, and other office supplies. Stationery includes materials to be written on by hand or by equipment such as computer printers.

An easel is an upright support used for displaying and/or fixing something resting upon it, at an angle of about 20° to the vertical. In particular, painters traditionally use an easel to support a painting while they work on it, normally standing up; easels are also sometimes used to display finished paintings. Artists' easels are still typically made of wood, in functional designs that have changed little for centuries, or even millennia, though new materials and designs exist. Easels are typically made from wood, aluminum or steel.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

A whiteboard is a glossy, usually white surface for making non-permanent markings. Whiteboards are analogous to blackboards, but with a smoother surface allowing for rapid marking and erasing of markings on their surface. The popularity of whiteboards increased rapidly in the mid-1990s and they have become a fixture in many offices, meeting rooms, school classrooms, public events and other work environments.

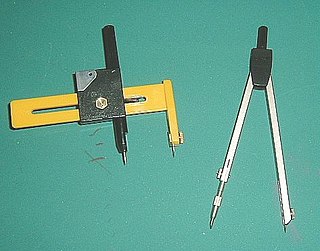

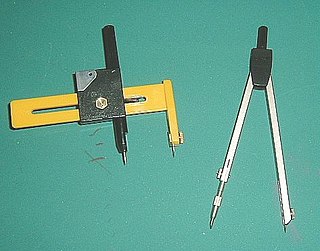

A compass, more accurately known as a pair of compasses, is a technical drawing instrument that can be used for inscribing circles or arcs. As dividers, it can also be used as a tool to mark out distances, in particular, on maps. Compasses can be used for mathematics, drafting, navigation and other purposes.

A penciller is an artist who works on the creation of comic books, graphic novels, and similar visual art forms, with a focus on the initial pencil illustrations, usually in collaboration with other artists, who provide inks, colors and lettering in the book, under the supervision of an editor.

A combination square is a multi-purpose measuring and marking tool used in metalworking, woodworking, and stonemasonry. It is composed of a rule and one or more interchangeable heads that can be attached to the rule. Other names for the tool include adjustable square, combo square, and sliding square.

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies and casting dies which are not. Like molds, dies are generally customized to the item they are used to create.

A goniometer is an instrument that either measures an angle or allows an object to be rotated to a precise angular position. The term goniometry derives from two Greek words, γωνία (gōnía) 'angle' and μέτρον (métron) 'measure'. The protractor is a commonly used type in the fields of mechanics, engineering, and geometry.

A scriber is a hand tool used in metal work to mark lines on workpieces, prior to machining. The process of using a scriber is called scribing and is just part of the process of marking out. It is used instead of pencils or ink lines, because the latter are hard to see, easily erased, and imprecise due to their wide mark; scribe lines are thin and semi-permanent. On non-coated workpieces marking blue is commonly used to increase the contrast of the mark lines.

A vise or vice is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. The jaws are often flat but may have grooves, adapt to the shape of the workpiece or be custom made.

A technical pen is a specialized instrument used by an engineer, architect, or drafter to make lines of constant width for architectural, engineering, or technical drawings. Technical pens may use either a refillable ink reservoir or a replaceable ink cartridge.

A countertop, also counter top, counter, benchtop, worktop or kitchen bench, bunker is a raised, firm, flat, and horizontal surface. They are built for work in kitchens or other food preparation areas, bathrooms or lavatories, and workrooms in general. The surface is frequently installed upon and supported by cabinets, positioned at an ergonomic height for the user and the particular task for which it is designed. A countertop may be constructed of various materials with different attributes of functionality, durability and aesthetics, and may have built-in appliances, or accessory items relative to the intended application.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

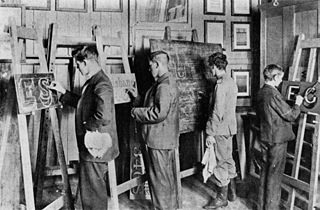

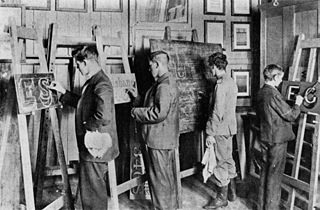

A drafter is an engineering technician who makes detailed technical drawings or plans for machinery, buildings, electronics, infrastructure, sections, etc. Drafters use computer software and manual sketches to convert the designs, plans, and layouts of engineers and architects into a set of technical drawings. Drafters operate as the supporting developers and sketch engineering designs and drawings from preliminary design concepts.

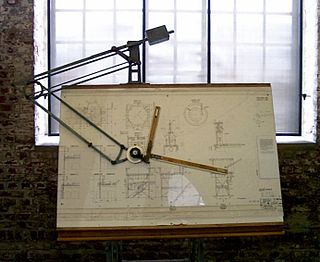

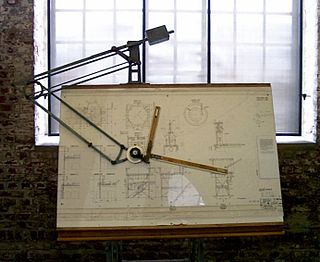

Drafting tools may be used for measurement and layout of drawings, or to improve the consistency and speed of creation of standard drawing elements. Tools such as pens and pencils mark the drawing medium. Other tools such as straight edges, assist the operator in drawing straight lines, or assist the operator in drawing complicated shapes repeatedly. Various scales and the protractor are used to measure the lengths of lines and angles, allowing accurate scale drawing to be carried out. The compass is used to draw arcs and circles. A drawing board was used to hold the drawing media in place; later boards included drafting machines that sped the layout of straight lines and angles. Tools such as templates and lettering guides assisted in the drawing of repetitive elements such as circles, ellipses, schematic symbols and text. Other auxiliary tools were used for special drawing purposes or for functions related to the preparation and revision of drawings. The tools used for manual technical drawing have been displaced by the advent of computer-aided drawing, drafting and design (CADD).

A drafting machine is a tool used in technical drawing, consisting of a pair of scales mounted to form a right angle on an articulated protractor head that allows an angular rotation.