Related Research Articles

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer or a die. Forging is often classified according to the temperature at which it is performed: cold forging, warm forging, or hot forging. For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons. Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery.

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spheroidal graphite cast iron and SG iron, is a type of graphite-rich cast iron discovered in 1943 by Keith Millis. While most varieties of cast iron are weak in tension and brittle, ductile iron has much more impact and fatigue resistance, due to its nodular graphite inclusions.

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing inertia to produce castings from a rubber mold. Typically, a disc-shaped mold is spun along its central axis at a set speed. The casting material, usually molten metal or liquid thermoset plastic, is then poured in through an opening at the top-center of the mold. The filled mold then continues to spin as the metal solidifies.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

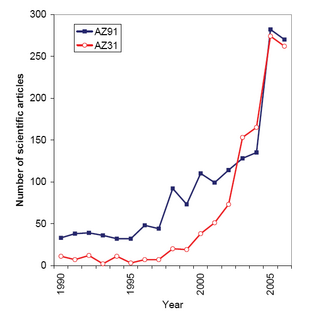

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern cars and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Spray forming, also known as spray casting, spray deposition and in-situ compaction, is a method of casting near net shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming an alloy is melted, normally in an induction furnace, then the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition, this provides sufficient liquid fraction to 'stick' the solid fraction together. Deposition continues, gradually building up a spray formed billet of metal on the substrate.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Fusible core injection molding, also known as lost core injection molding, is a specialized plastic injection molding process used to mold internal cavities or undercuts that are not possible to mold with demoldable cores. Strictly speaking the term "fusible core injection molding" refers to the use of a fusible alloy as the core material; when the core material is made from a soluble plastic the process is known as soluble core injection molding. This process is often used for automotive parts, such as intake manifolds and brake housings, however it is also used for aerospace parts, plumbing parts, bicycle wheels, and footwear.

Ceramic foam is a tough foam made from ceramics. Manufacturing techniques include impregnating open-cell polymer foams internally with ceramic slurry and then firing in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminium oxide, a common high-temperature ceramic, and gets insulating properties from the many tiny air-filled voids within the material.

Ceramic mold casting, also known ambiguously as ceramic molding, is a group of metal casting processes that use ceramics as the mold material. It is a combination of plaster mold casting and investment casting. There are two types of ceramic mold casting: the Shaw process and the Unicast process.

Friction stir processing (FSP) is a method of changing the properties of a metal through intense, localized plastic deformation. This deformation is produced by forcibly inserting a non-consumable tool into the workpiece, and revolving the tool in a stirring motion as it is pushed laterally through the workpiece. The precursor of this technique, friction stir welding, is used to join multiple pieces of metal without creating the heat affected zone typical of fusion welding.

An inclusion is a solid particle in liquid aluminium alloy. It is usually non-metallic and can be of different nature depending on its source.

In continuum mechanics, time-dependent viscosity is a property of fluids whose viscosity changes as a function of time. The most common type of this is thixotropy, in which the viscosity of fluids under continuous shear decreases with time; the opposite is rheopecty, in which viscosity increases with time.

Friction extrusion is a thermo-mechanical process that can be used to form fully consolidated wire, rods, tubes, or other non-circular metal shapes directly from a variety of precursor charges including metal powder, flake, machining waste or solid billet. The process imparts unique, and potentially, highly desirable microstructures to the resulting products. Friction extrusion was invented at The Welding Institute in the UK and patented in 1991. It was originally intended primarily as a method for production of homogeneous microstructures and particle distributions in metal matrix composite materials.

While chemically pure materials have a single melting point, chemical mixtures often partially melt at the temperature known as the solidus (TS or Tsol), and fully melt at the higher liquidus temperature (TL or Tliq). The solidus is always less than or equal to the liquidus, but they need not coincide. If a gap exists between the solidus and liquidus it is called the freezing range, and within that gap, the substance consists of a mixture of solid and liquid phases (like a slurry). Such is the case, for example, with the olivine (forsterite-fayalite) system, which is common in Earth's mantle.

References

Notes

- ↑ "Welcome to MyNADCA!". diecasting.org. Retrieved 2015-08-20.

- 1 2 Young 2006, p. 1.

- 1 2 3 4 5 6 7 Lowe, Anthony; Ridgway, Keith; Atkinson, Helen (September 1999), "Thixoforming", Materials World, 7 (9): 541–543.

- ↑ Vinarcik, Edward J. (2003), High integrity die casting processes, vol. 1, Wiley-IEEE, pp. 91–101, ISBN 978-0-471-20131-1.

- ↑ Kapranos, Plato (2008). Proc. 10th Inter. Conf. Semi-Solid Processing of Alloys and Composites. Aachen, Germany & Liege, Belgium.

{{cite conference}}: Missing or empty|title=(help) - 1 2 3 4 Zirps, Melissa (2024-01-15). "How Thixomolding is Redefining Electric Vehicle Production". Light Metal Age Magazine. Retrieved 2024-08-19.

- ↑ LeBeau, S.; Decker, R. (1998). Microstructural Design of Thixomolded Magnesium Alloys. Proc. 5th Inter. Conf. Semi-Solid Processing of Alloys and Composites. Golden, Colorado.

- 1 2 Midson, Stephen P. (September 2008). "Semi-Solid Casting of Aluminum Alloys: An Update". Die Casting Engineer.

- 1 2 John L., Jorstad (September 2006), "Aluminum Future Technology in Die Casting" (PDF), Die Casting Engineering: 18–25, archived (PDF) from the original on 2011-06-14.

- ↑ Midson, Stephen P.; Kilbert, Robert K.; Le Beau, Stephen E.; Decker, Raymond (2004). Guidelines for Producing Magnesium Thixomolded Semi-Solid Components used in Structural Applications. Proc. 8th Inter. Conf. Semi-Solid Processing of Alloys and Composites. Limasol, Cyprus.

- ↑ Young 2006, p. 2.

- ↑ Midson, Stephen p. (1996). NADCA Semi-Solid & Squeeze Casting Conference. Rosemont, Illinois.

{{cite conference}}: Missing or empty|title=(help)

Bibliography

- Young, Kenneth P. (2006), Semi-Solid Metal Casting: Reducing the Cost of Copper Alloy Parts (PDF), Massachusetts Office of Technical Assistance, archived from the original (PDF) on 2006-10-07.