An operational definition specifies concrete, replicable procedures designed to represent a construct. In the words of American psychologist S.S. Stevens (1935), "An operation is the performance which we execute in order to make known a concept." For example, an operational definition of "fear" often includes measurable physiologic responses that occur in response to a perceived threat. Thus, "fear" might be operationally defined as specified changes in heart rate, galvanic skin response, pupil dilation, and blood pressure.

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. It is measured as BHN, Brinell Hardness Number, and was named for Johan August Brinell.

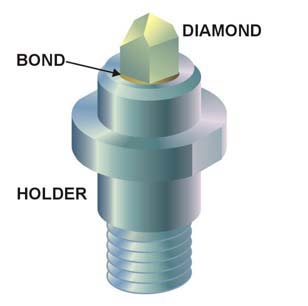

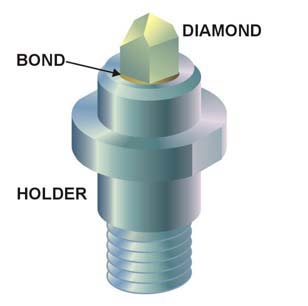

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of pascals, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not pressure.

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale.

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known load, for a specified dwell time, and the resulting indentation is measured using a microscope. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1 and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge. The depth of the indentation can be approximated as 1/30 of the long dimension. The Knoop hardness HK or KHN is then given by the formula:

In materials science, hardness is a measure of the resistance to localized plastic deformation, such as an indentation or a scratch (linear), induced mechanically either by pressing or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be contrasted with soft matter.

August Brinell was a Swedish metallurgical engineer.

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material.

The Shore durometer is a device for measuring the hardness of a material, typically of polymers.

A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels.

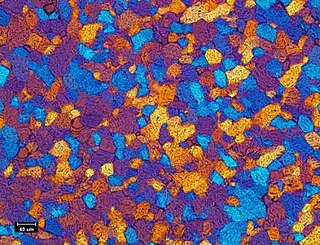

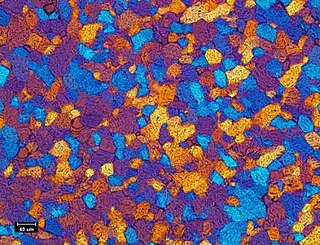

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 μm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

The Barcol hardness test characterizes the indentation hardness of materials through the depth of penetration of an indentor, loaded on a material sample and compared to the penetration in a reference material. The method is most often used for composite materials such as reinforced thermosetting resins or to determine how much a resin or plastic has cured. The test complements the measurement of glass transition temperature, as an indirect measure of the degree of cure of a composite. It is inexpensive and quick, and provides information on the cure throughout a part.

Brinelling is the permanent indentation of a hard surface. It is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force, and the depth and diameter of the mark indicates the Brinell hardness of the surface. Brinelling is permanent plastic deformation of a surface, and usually occurs while two surfaces in contact are stationary and the material yield strength has been exceeded.

The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, , is defined as the maximum load, divided by the projected area of the indent, .

Meyer's law is an empirical relation between the size of a hardness test indentation and the load required to leave the indentation. The formula was devised by Eugene Meyer of the Materials Testing Laboratory at the Imperial School of Technology, Charlottenburg, Germany, circa 1908.

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called depth sensing indentation or instrumented indentation, gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties.

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces.

The Korsunsky work-of-indentation approach is a method of extracting values of hardness and stiffness for a small volume of material from indentation test data, first developed by Alexander M. Korsunsky.

Indentation plastometry is the idea of using an indentation-based procedure to obtain (bulk) mechanical properties in the form of stress-strain relationships in the plastic regime. Since indentation is a much easier and more convenient procedure than conventional tensile testing, with far greater potential for mapping of spatial variations, this is an attractive concept.