In computing, a printer is a peripheral machine which makes a durable representation of graphics or text, usually on paper. While most output is human-readable, bar code printers are an example of an expanded use for printers. Different types of printers include 3D printers, inkjet printers, laser printers, and thermal printers.

Printing is a process for mass reproducing text and images using a master form or template. The earliest non-paper products involving printing include cylinder seals and objects such as the Cyrus Cylinder and the Cylinders of Nabonidus. The earliest known form of printing evolved from ink rubbings made on paper or cloth from texts on stone tablets, used during the sixth century. Printing by pressing an inked image onto paper appeared later that century. Later developments in printing technology include the movable type invented by Bi Sheng around 1040 and the printing press invented by Johannes Gutenberg in the 15th century. The technology of printing played a key role in the development of the Renaissance and the Scientific Revolution and laid the material basis for the modern knowledge-based economy and the spread of learning to the masses.

Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics by repeatedly passing a laser beam back and forth over a negatively charged cylinder called a "drum" to define a differentially charged image. The drum then selectively collects electrically charged powdered ink (toner), and transfers the image to paper, which is then heated to permanently fuse the text, imagery, or both, to the paper. As with digital photocopiers, laser printers employ a xerographic printing process. Laser printing differs from traditional xerography as implemented in analog photocopiers in that in the latter, the image is formed by reflecting light off an existing document onto the exposed drum.

Dot matrix printing, sometimes called impact matrix printing, is a computer printing process in which ink is applied to a surface using a relatively low-resolution dot matrix for layout. Dot matrix printers are a type of impact printer that prints using a fixed number of pins or wires and typically use a print head that moves back and forth or in an up-and-down motion on the page and prints by impact, striking an ink-soaked cloth ribbon against the paper. They were also known as serial dot matrix printers. Unlike typewriters or line printers that use a similar print mechanism, a dot matrix printer can print arbitrary patterns and not just specific characters.

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals.

Dye-sublimation printing is a term that covers several distinct digital computer printing techniques that involve using heat to transfer dye onto a substrate.

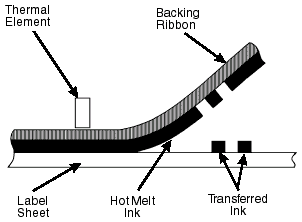

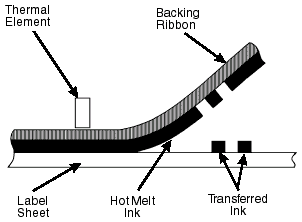

Thermal-transfer printing is a digital printing method in which material is applied to paper by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with direct thermal printing, where no ribbon is present in the process.

Digital printing is a method of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

Thermal printing is a digital printing process which produces a printed image by passing paper with a thermochromic coating, commonly known as thermal paper, over a print head consisting of tiny electrically heated elements. The coating turns black in the areas where it is heated, producing an image.

A minilab is a small photographic developing and printing system or machine, as opposed to large centralized photo developing labs. Many retail stores use film or digital minilabs to provide on-site photo finishing services.

HP Indigo Division is a division of HP Inc.'s Graphic Solutions Business. It was founded in 1977 in Israel and acquired by Hewlett-Packard in 2001. HP Indigo develops, manufactures and markets digital printing solutions, including printing presses, proprietary consumables/supplies and workflow solutions. HP Indigo has offices around the world, with headquarters in Ness Ziona, Israel.

Solid ink is a type of ink used in printing. Solid ink is a waxy, resin-based polymer that must be melted prior to usage, unlike conventional liquid inks. The technology is used most often in graphics and large-format printing environments where color vividness and cost efficiency are important.

Flatbed digital printers, also known as flatbed printers or flatbed UV printers, are printers characterized by a flat surface upon which a material is placed to be printed on. Flatbed printers are capable of printing on a wide variety of materials such as photographic paper, film, cloth, plastic, pvc, acrylic, glass, ceramic, metal, wood, leather, etc.). Flatbed digital printers usually use UV curable inks made of acrylic monomers that are then exposed to strong UV-light to cure, or polymerize them. This process allows for printing on a wide variety of surfaces such as wood or canvas, carpet, tile, and even glass. The adjustable printing bed makes it possible to print on surfaces ranging in thickness from a sheet of paper often up to as much as several inches. Typically used for commercial applications, flatbed printing is often a substitute for screen-printing. Since no printing plates or silkscreens must be produced, digital printing technology allows shorter runs of signs to be produced economically. Many of the high-end flatbed printers allow for roll-feed, allowing for unattended printing.

Suny Cellular Communication was known as Scitex Corporation Ltd. until December 2005 and Scailex Corporation Ltd. until November 2016.

Tonejet is a drop-on-demand inkjet printing technology that enables the direct digital deposition of printing ink onto substrates. The Tonejet digital printing process is targeted at commercial and industrial applications.

Digital embossing is a digital printing technology enhancement process. Digital embossing eliminates the need for printing plates, molds, chemicals, and solvents. The process emits no pollutants or waste and reduces energy use. The high resolution inkjet technology enables selective coating with variable thickness and stampless embossing. Digital embossing allows for on-demand printing of as few as one item in thousands of copies.

Kornit Digital Ltd. is an Israeli-American international manufacturing company. It produces high-speed industrial inkjet printers, pigmented ink and chemical products for the garment and apparel, home goods, textile accessories and decorating industry.

The RemaxWorld Expo is an annual trade show comprising vendors from within the print consumables industry. The event began in 2007, resulting from a joint venture between the China Council for the Promotion of International Trade (CCPIT) and Recycling Times Media Corporation. Centered in Zhuhai, widely recognized as being the print consumables capital of the world, the exhibition currently takes place in the newly constructed Zhuhai International Convention & Exhibition Center. In 2015, the show accommodated 463 exhibitors and 13,938 visitors from 83 countries.

Inkjet solar cells are solar cells manufactured by low-cost, high tech methods that use an inkjet printer to lay down the semiconductor material and the electrodes onto a solar cell substrate.

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the 1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition.