A utility knife is any type of knife used for general manual work purposes. Such knives were originally fixed-blade knives with durable cutting edges suitable for rough work such as cutting cordage, cutting/scraping hides, butchering animals, cleaning fish scales, reshaping timber, and other tasks. Craft knives are small utility knives used as precision-oriented tools for finer, more delicate tasks such as carving and papercutting.

A propeller is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are specially shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft with an approximately horizontal axis.

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools.

A circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

Scissors are hand-operated shearing tools. A pair of scissors consists of a pair of metal blades pivoted so that the sharpened edges slide against each other when the handles (bows) opposite to the pivot are closed. Scissors are used for cutting various thin materials, such as paper, cardboard, metal foil, cloth, rope, and wire. A large variety of scissors and shears all exist for specialized purposes. Hair-cutting shears and kitchen shears are functionally equivalent to scissors, but the larger implements tend to be called shears. Hair-cutting shears have specific blade angles ideal for cutting hair. Using the incorrect type of scissors to cut hair will result in increased damage or split ends, or both, by breaking the hair. Kitchen shears, also known as kitchen scissors, are intended for cutting and trimming foods such as meats.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

A pencil sharpener is a tool for sharpening a pencil's writing point by shaving away its worn surface. Pencil sharpeners may be operated manually or by an electric motor. It is common for many sharpeners to have a casing around them, which can be removed for emptying the pencil shavings debris into a bin.

Sheep shearing is the process by which the woollen fleece of a sheep is cut off. The person who removes the sheep's wool is called a shearer. Typically each adult sheep is shorn once each year. The annual shearing most often occurs in a shearing shed, a facility especially designed to process often hundreds and sometimes more than 3,000 sheep per day.

A bolt cutter, sometimes called bolt cropper, is a tool used for cutting bolts, chains, padlocks, rebar and wire mesh. It typically has long handles and short blades, with compound hinges to maximize leverage and cutting force. A typical bolt cutter yields 20 kilonewtons (4,500 lbf) of cutting force for a 250 newtons (56 lbf) force on the handles.

Diagonal pliers are pliers intended for the cutting of wire. The plane defined by the cutting edges of the jaws intersects the joint rivet at an angle or "on a diagonal", hence the name.

A jointer or in some configurations, a jointer-planer is a woodworking machine used to produce a flat surface along a board's length. As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels. A planer-jointer setup has the width that enables smoothing ('surface planing') and leveling the faces (widths) of boards small enough to fit the tables.

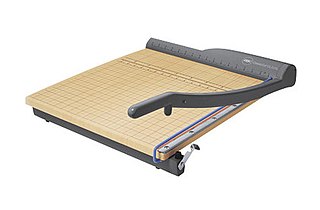

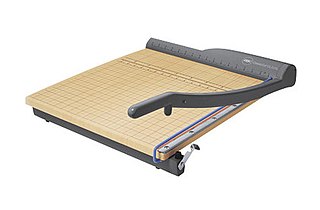

A paper cutter, also known as a paper guillotine or simply a guillotine, is a tool often found in offices and classrooms, designed to administer straight cuts to single sheets or large stacks of paper at once.

A pizza cutter is a utensil that is used to cut pizzas.

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals. There are several different types of single edge cutting tools that are made from a variety of hardened metal alloys that are ground to a specific shape in order to perform a specific part of the turning process resulting in a finished machined part. Single edge cutting tools are used mainly in the turning operations performed by a lathe in which they vary in size as well as alloy composition depending on the size and the type of material being turned. These cutting tools are held stationary by what is known as a tool post which is what manipulates the tools to cut the material into the desired shape. Single edge cutting tools are also the means of cutting material performed by metal shaping machines and metal planing machines which removes material by means of one cutting edge. Milling and drilling tools are often multipoint tools. Drilling is exclusively used to make holes in a workpiece. All drill bits have two cutting edges that are ground into two equally tapered angles which cuts through the material by applying downward rotational force. Endmills or milling bits, which also cut material by rotational force. Although these tools are not made to put holes in a workpiece. They cut by horizontal shear deformation in which the workpiece is brought into the tool as it's rotating. This is known as the tool path which is determined by the axis of the table that is holding the workpiece in place. This table is designed to accept a variety of vises and clamping tools so that it can move into the cutter at various angles and directions while the workpiece remains still. There are several different types of endmills that perform a certain type of milling action.

Book scanning or book digitization is the process of converting physical books and magazines into digital media such as images, electronic text, or electronic books (e-books) by using an image scanner.

A cheese knife is a type of kitchen knife specialized for the cutting of cheese. Different cheeses require different knives, according primarily to hardness. There are also a number of other kitchen tools designed for cutting or slicing cheese, especially the harder types. These include the cheese cutter, cheese slicer, cheese plane and others.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

There are many types of shears used to shear or cut sheet metal.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.