Related Research Articles

Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems can be local-based or cloud-based. Cloud-based applications have grown in recent years due to the increased efficiencies arising from information being readily available from any location with Internet access.

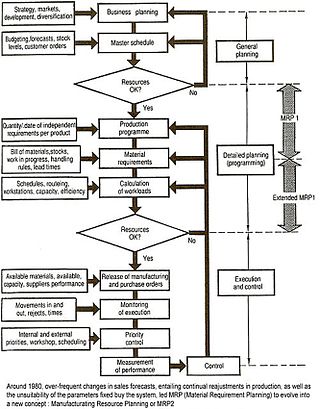

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods that have been ordered and focus on efficiency, productivity, and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities that do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

A management information system (MIS) is an information system used for decision-making, and for the coordination, control, analysis, and visualization of information in an organization. The study of the management information systems involves people, processes and technology in an organizational context. In other words, it serves, as the functions of controlling, planning, decision making in the management level setting.

Baan was a vendor of enterprise resource planning (ERP) software that is now owned by Infor Global Solutions. Baan or Baan ERP, was also the name of the ERP product created by this company.

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

A warehouse management system (WMS) is a set of policies and processes intended to organise the work of a warehouse or distribution centre, and ensure that such a facility can operate efficiently and meet its objectives.

QAD Inc. is a software company that provides enterprise resource planning (ERP) software and related enterprise software to manufacturing companies. The company has customers in over 100 countries around the world.

SSA Global Technologies was a company developing Enterprise resource planning (ERP) software. On May 15, 2006, SSA Global announced that it would be acquired by Infor Global Solutions. The acquisition was completed on July 28, 2006.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Oracle Applications comprise the applications software or business software of the Oracle Corporation both in the cloud and on-premises. The term refers to the non-database and non-middleware parts. The suite of applications includes enterprise resource planning, enterprise performance management, supply chain & manufacturing, human capital management, and advertising and customer experience.

Safety stock is a term used by logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts caused by uncertainties in supply and demand. Adequate safety stock levels permit business operations to proceed according to their plans. Safety stock is held when uncertainty exists in demand, supply, or manufacturing yield, and serves as an insurance against stockouts.

Procurement software refers to a range of business software designed to streamline and automate purchasing processes for businesses and organizations. By managing information flows and transactions between procuring entities, suppliers, and partners, procurement software aims to cut costs, improve efficiency, and boost organizational performance.

Field inventory management, commonly known as inventory management, is the task of understanding the stock mix of a company and the handling of the different demands placed on that stock. The demands are influenced by both external and internal factors and are balanced by the creation of purchase order requests to keep supplies at a reasonable or prescribed level. Inventory management is important for every other business enterprise.

Backflush accounting is a subset of management accounting focused on types of "postproduction issuing;" It is a product costing approach, used in a Just-In-Time (JIT) operating environment, in which costing is delayed until goods are finished. Backflush accounting delays the recording of costs until after the events have taken place, then standard costs are used to work backwards to 'flush' out the manufacturing costs. The result is that detailed tracking of costs is eliminated. Journal entries to inventory accounts may be delayed until the time of product completion or even the time of sale, and standard costs are used to assign costs to units when journal entries are made. The backflushing transaction has two steps: one step of the transaction reports the produced part which serves to increase the quantity on-hand of the produced part and a second step which relieves the inventory of all the component parts. Component part numbers and quantities-per are taken from the standard bill of material (BOM). This represents a huge saving over the traditional method of a) issuing component parts one at a time, usually to a discrete work order, b) receiving the finished parts into inventory, and c) returning any unused components, one at a time, back into inventory.

A master production schedule (MPS) is a plan for individual commodities to be produced in each time period such as production, staffing, inventory, etc. It is usually linked to manufacturing where the plan indicates when and how much of each product will be demanded. This plan quantifies significant processes, parts, and other resources in order to optimize production, to identify bottlenecks, and to anticipate needs and completed goods. Since a MPS drives much factory activity, its accuracy and viability dramatically affect profitability. Typical MPSs are created by software with user tweaking.

Openbravo is a Spanish cloud-based SaaS software provider specializing in retail with headquarters in Pamplona, Spain and offices in Barcelona and Lille. The company was formerly known for being a horizontal open-source enterprise resource planning (ERP) software vendor for different industries.

Distribution Center Management System (DCMS) is a proprietary end-user warehouse management system, designed to track the activities performed in a distribution center or warehouse. It is created and owned by a private company, Eclipse Systems Pvt Ltd. It automates the entire process flow of receiving, managing, and shipping goods to customers from the warehouse. DCMS solutions are designed for both large and small-scale businesses. In January 2015, the product went open source.

Adaxa Suite is a fully integrated open-source Enterprise Resource Planning (ERP) Suite.

The inoERP enterprise management system is an open-source Go and Flutter based Enterprise Resource Planning (ERP) application which can be used with MySQL, MariaDB or Oracle 12c databases. The objective of inoERP is to provide a dynamic pull based system where the demand /supply changes frequently and traditional planning systems are unable to provide a good inventory turn.

References

- 1 2 3 Woodie, Alex. "SSA Delivers New ERP LX Platform for iSeries". IT Jungle. Retrieved 20 May 2015.

- ↑ "Infor ERP BPCS/LX Document Management". YouTube. 2011. Archived from the original on 2016-03-10. Retrieved 10 June 2015.

- 1 2 "System Software Associates, Inc. History". Funding Universe. Retrieved 20 May 2015.

- ↑ "Cloud Based Payroll Software". info.microkeeper. Retrieved 2024-09-23.