Developments

The gas fields were developed through an array of platforms and subsea facilities. These were as shown in the following table, together with data on the peak rate and cumulative production of gas in million cubic metres (mcm). [4] [5] [2] [3]

| Installation | Structure | Start-up | Production to | Pipeline length and diameter | Peak production, mcm/y | Year of peak | Cumulative production to 2014, mcm |

|---|---|---|---|---|---|---|---|

| Boulton BM | Steel jacket | 1997 | Murdoch MD | 11 km, 10” | 925 | 1998 | 7,185 |

| Boulton HM | Subsea | 2002 | Watt QM | 140 | 2004 | 357 | |

| Caister CM | Steel jacket | 1993 | Murdoch MD | 11 km, 16” | 388 (Bunter) | 1995 | 3,202 |

| 745 (Carboniferous) | 1995 | 5,156 | |||||

| Cavendish RM | Steel jacket | 2006 | Murdoch MD via Cavendish manifold | 47.2 km, 10” | 649 | 2008 | 2,480 |

| Hawksley EM | Subsea | 2002 | Murdoch MD via manifold | 22 km, 12” | 610 | 2003 | 1,464 |

| Hunter HK | Subsea | 2006 | Murdoch K KM | 6.2 km, 8” | 24 | 2008 | 41 |

| Katy KT | Steel 3-legs | 2012 | Kelvin TM–Murdock MD pipeline | 14 km, 10” | 200 | 2013 | 200 |

| Kelvin TM | Steel 3-legs | 2007 | Murdoch MD via manifold | 12.5 km, 12” | 457 | 2008 | 738 |

| Ketch KA | Steel jacket | 1999 | Murdoch MD | 28 km, 18” | 1,233 | 2000 | 6,407 |

| McAdam MM | Subsea | 2003 | Hawksley–Murdoch pipeline | 926 | 2006 | 3,691 | |

| Munro MH | Steel 3-legs | 2005 | Hawksley EM | 5 km, 10” | 354 | 2006 | 1,379 |

| Murdoch K KM | Subsea | 2002 | Murdoch MD via manifold | 5.5 km, 10” | 1,378 | 2003 | 5,682 |

| Murdoch MD | Steel jacket | 1993 | Theddlethorpe | 188 km, 26” | 1,063 | 1994 | 13,606 |

| Murdoch MC | Steel jacket | 1993 | Murdoch MD | – | – | – | – |

| Murdoch MA | Steel jacket | 1993 | – | – | – | – | – |

| Rita | Subsea | 2009 | Hunter HK | 14 km, 8” | 506 | 2010 | 1,086 |

| Schooner SA | Steel jacket | 1996 | Murdoch MD | 30 km, 16” | 1,245 | 1997 | 8,659 |

| Topaz | Subsea | 2009 | Schooner SA | 15.5 km, 6” | 94 | 2010 | 198 |

| Watt QM | Subsea | 2003 | Murdoch MD via manifold | 17 km, 10” | 16 | 2004 | 16 |

In addition to the gas pipelines there was also a methanol distribution system. Methanol/corrosion inhibitor was pumped from TGT through a 4-inch pipeline to Murdoch MD. From here it was distributed to the platforms and wellheads through 3-inch and 2-inch pipelines. [6]

New pipeline reception facilities and process plant was installed at TGT as part of the CMS development.

Production

The production profile, in mcm/y, of the Murdoch field was as shown. [3]

Graphs are temporarily unavailable due to technical issues. |

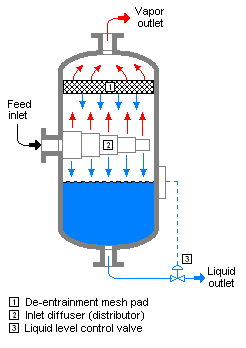

Gas compression

Wellhead gas from the individual fields was routed to either the Suction, the Interstage or the Discharge Manifold on Murdoch MC depending on its pressure. [7] Gas from the Suction Manifold was routed to the Suction Slug Catcher where liquids were removed. Gas flowed successively to the LP Suction Scrubber, the First Stage Gas Compressor and the Intercooler. Here it was comingled with gas from the Interstage Manifold which had flowed through the Interstage Slug Catcher. The combined flow was routed to the Interstage Scrubber, the Second Stage Gas Compressor and the Export Gas Cooler. Gas was returned to the MD platform and to the Theddlethorpe trunk line. Recovered liquids were injected into the trunk line. [7]

To increase the compression capacity a compressor module was added to the Murdoch MC platform in 2003. [8]

Telecommunications

Murdoch MD was connected to the Tampnet (formerly NorSea Com-1) submarine telecommunications cable system. [9] It has landing points at Lowestoft, Suffolk, UK and Kårstø, Rogaland, Norway. It is connected to:

1. Draupner platform, operated by Gassco

2. Ula oil field, operated by BP

3. Ekofisk, operated by ConocoPhillips

4. Valhall oil field, operated by BP

5. Murdoch gas field, operated by ConocoPhillips (now disconnected) [9]