Clothing is any item worn on the body. Typically, clothing is made of fabrics or textiles, but over time it has included garments made from animal skin and other thin sheets of materials and natural products found in the environment, put together. The wearing of clothing is mostly restricted to human beings and is a feature of all human societies. The amount and type of clothing worn depends on gender, body type, social factors, and geographic considerations. Garments cover the body, footwear covers the feet, gloves cover the hands, while hats and headgear cover the head, and underwear covers the private parts.

Linen is a textile made from the fibers of the flax plant.

A clothes hanger, coat hanger, or coathanger, or simply a hanger, is a hanging device in the shape/contour of:

Laundry is the washing of clothing and other textiles, and, more broadly, their drying and ironing as well. Laundry has been part of history since humans began to wear clothes, so the methods by which different cultures have dealt with this universal human need are of interest to several branches of scholarship.

A washing machine is a machine designed to launder clothing. The term is mostly applied to machines that use water. Other ways of doing laundry include dry cleaning and ultrasonic cleaning.

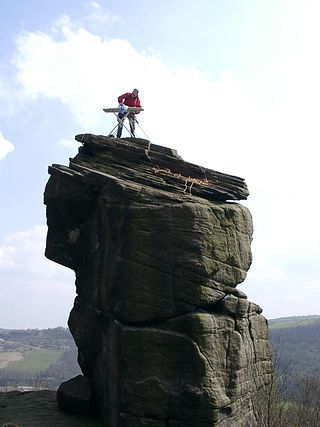

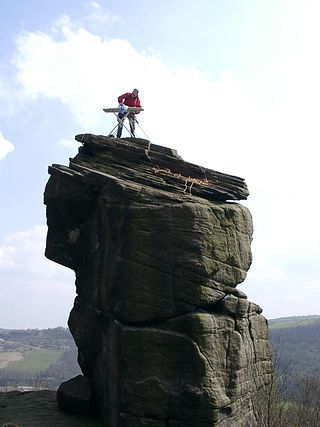

Extreme Ironing is an extreme sport in which people take ironing boards to remote locations and iron items of clothing. According to the Extreme Ironing Bureau, extreme ironing is "the latest dangerous sport that combines the thrills of an extreme outdoor activity with the satisfaction of a well-pressed shirt."

A clothes dryer is a powered household appliance that is used to remove moisture from a load of clothing, bedding and other textiles, usually after they are washed in the washing machine.

A clothes iron is a small appliance that, when heated, is used to press clothes to remove wrinkles and unwanted creases. Domestic irons generally range in operating temperature from between 121 °C (250 °F) to 182 °C (360 °F). It is named for the metal (iron) of which the device was historically made, and the use of it is generally called ironing, the final step in the process of laundering clothes.

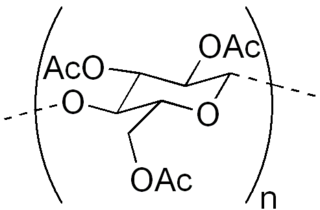

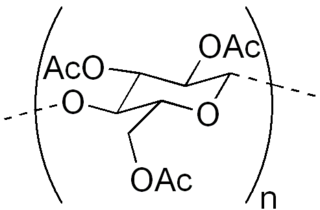

Cellulose triacetate, triacetate, CTA or TAC is a chemical compound produced from cellulose and a source of acetate esters, typically acetic anhydride. Triacetate is commonly used for the creation of fibres and film base. It is chemically similar to cellulose acetate. Its distinguishing characteristic is that in triacetate, at least "92 percent of the hydroxyl groups are acetylated." During the manufacture of triacetate, the cellulose is completely acetylated; whereas in normal cellulose acetate or cellulose diacetate, it is only partially acetylated. Triacetate is significantly more heat resistant than cellulose acetate.

Linens are fabric household goods intended for daily use, such as bedding, tablecloths, and towels. "Linens" may also refer to church linens, meaning the altar cloths used in church.

A trouser press, also referred to by the trademarked name Corby trouser press, is an electrical appliance used to smooth the wrinkles from a pair of trousers. They are commonly provided in hotel rooms worldwide, though may also be purchased for home use; they are generally associated with use by businessmen who require a formal appearance to their suit.

Jiffy Steamer, located in Union City, Tennessee, manufactures a variety of clothing steamers. Jiffy Steamer was founded in 1940.

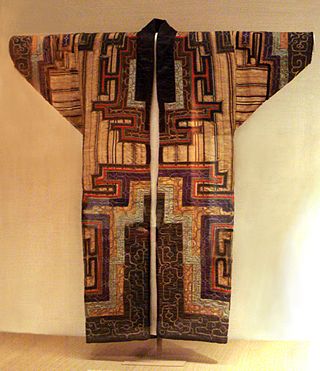

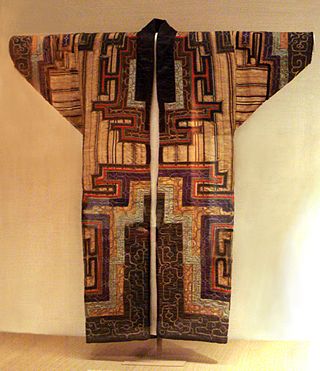

The conservation and restoration of textiles refers to the processes by which textiles are cared for and maintained to be preserved from future damage. The field falls under the category of art conservation, heritage conservation as well as library preservation, depending on the type of collection. The concept of textile preservation applies to a wide range of artifacts, including tapestries, carpets, quilts, clothing, flags and curtains, as well as objects which "contain" textiles, such as upholstered furniture, dolls, and accessories such as fans, parasols, gloves and hats or bonnets. Many of these artifacts require specialized care, often by a professional conservator.

A tunnel finisher is a machine that removes wrinkles from garments and is often used in the textile industry. As with other industrial pressing equipment, this machine is employed to improve the quality and look of a textile product. It has a chamber called a "tunnel" and includes a conveyor fed unit through which the garments are steamed and dried. The machine also features hook systems; air curtain entrance to eliminate moisture or condensation; cotton care and roller units; exhaust steam, and a preconditioning module.

Steam is water vapour, often mixed with air and/or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Steam that is saturated or superheated is invisible; however, wet steam, a visible mist or aerosol of water droplets, is often referred to as "steam".

Ironing is the use of an iron, usually heated, to remove wrinkles and unwanted creases from fabric. The heating is commonly done to a temperature of 180–220 °C (360–430 °F), depending on the fabric. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics are advertised as needing little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining wrinkle-resistant polyester with cotton.

PVC clothing is shiny clothing made from the plastic polyvinyl chloride (PVC). PVC plastic is often called "vinyl" and this type of clothing is commonly known as vinyl clothing. PVC is sometimes confused with the similarly shiny patent leather.

Wrinkle-resistant or permanent press or durable press is a finishing method for textiles that avoids creases and wrinkles and provides a better appearance for the articles. Most cellulosic fabrics and blends of cellulosic-rich fabrics tend to crease or wrinkle. A durable press finish makes them dimensionally stable and crease-free. The finishing includes chemical finishing as well as mechanical finishing. Wrinkle-resistant finishes were developed in the early 20th century as a way to deal with fabrics derived from cotton, rayon, and linen, which were found to wrinkle easily and retain the wrinkles. These treatments have a lasting effect on the fabric. Synthetics like polyester, nylon, acrylic, and olefin have a natural resistance to wrinkles and a greater stability since they do not absorb water as efficiently.

Fabric treatments are processes that make fabric softer, or water resistant, or enhance dye penetration after they are woven. Fabric treatments get applied when the textile itself cannot add other properties. Treatments include, scrim, foam lamination, fabric protector or stain repellent, anti microbial and flame retardant.

The London shrunk, or London shrinkage, process was an 18th-century textile finishing process designed to preshrink wool fabrics and minimize their tendency to shrink before being used for making garments. When compared to the traditional steam shrinking method of controlling shrinkage, London shrinkage provided more permanent results in terms of reducing the likelihood of fabric shrinkage. London shrunk was found to be effective for fine worsteds, it was not typically used for woolens.