Pressure is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure is the pressure relative to the ambient pressure.

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

Boiling or ebullition is the rapid phase transition from liquid to gas or vapor; the reverse of boiling is condensation. Boiling occurs when a liquid is heated to its boiling point, so that the vapour pressure of the liquid is equal to the pressure exerted on the liquid by the surrounding atmosphere. Boiling and evaporation are the two main forms of liquid vapourization.

A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off the supply valve and observing whether there is a pressure loss. The location of a leak can be visually identified more easily if the water contains a colorant. Strength is usually tested by measuring permanent deformation of the container.

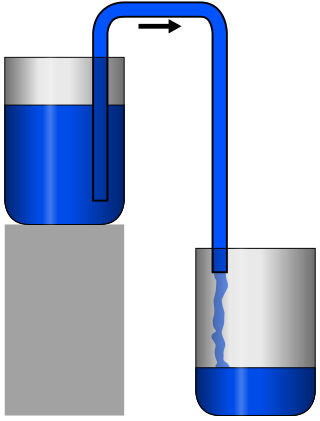

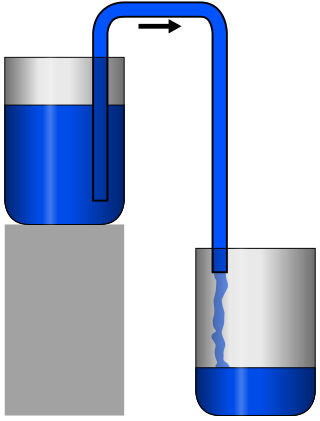

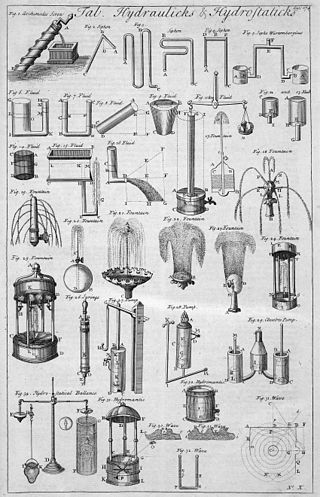

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

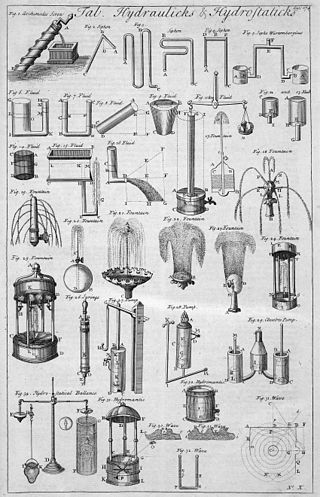

Fluid statics or hydrostatics is the branch of fluid mechanics that studies fluids at hydrostatic equilibrium and "the pressure in a fluid or exerted by a fluid on an immersed body".

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

A drain-waste-vent system is the combination of pipes and plumbing fittings that captures sewage and greywater within a structure and routes it toward a water treatment system. It includes venting to the exterior environment to prevent a vacuum from forming and impeding fixtures such as sinks, showers, and toilets from draining freely, and employs water-filled traps to block dangerous sewer gasses from entering a plumbed structure.

A gas cylinder is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus.

An air gap, as related to the plumbing trade, is the unobstructed vertical space between the water outlet and the flood level of a fixture. Air gaps of appropriate design are legally required by water health and safety regulations in many countries. An air gap is the simplest form of a backflow prevention device.

A leak is a way for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually unintended and therefore undesired. The word leak usually refers to a gradual loss; a sudden loss is usually called a spill.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

Bunding, also called a bund wall, is a constructed retaining wall around storage "where potentially polluting substances are handled, processed or stored, for the purposes of containing any unintended escape of material from that area until such time as a remedial action can be taken."

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form. The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally the latter detect levels that are excessively high or low.

Storage tanks are containers that hold liquids or compressed gases. The term can be used for reservoirs, and for manufactured containers. The usage of the word "tank" for reservoirs is uncommon in American English but is moderately common in British English. In other countries, the term tends to refer only to artificial containers. In the U.S., storage tanks operate under no pressure, distinguishing them from pressure vessels.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

In plumbing, a trap is a U-shaped portion of pipe designed to trap liquid or gas to prevent unwanted flow; most notably sewer gases from entering buildings while allowing waste materials to pass through. In oil refineries, traps are used to prevent hydrocarbons and other dangerous gases and chemical fumes from escaping through drains. In heating systems, the same feature is used to prevent thermo-siphoning which would allow heat to escape to locations where it is not wanted. Similarly, some pressure gauges are connected to systems using U bends to maintain a local gas while the system uses liquid. For decorative effect, they can be disguised as complete loops of pipe, creating more than one U for added efficacy.

A hydraulic telegraph refers to two different semaphore systems involving the use of water-based mechanisms as a telegraph. The earliest one was developed in 4th-century BC Greece, while the other was developed in 19th-century AD Britain. The Greek system was deployed in combination with semaphoric fires, while the latter British system was operated purely by hydraulic fluid pressure.

Vertical pressure variation is the variation in pressure as a function of elevation. Depending on the fluid in question and the context being referred to, it may also vary significantly in dimensions perpendicular to elevation as well, and these variations have relevance in the context of pressure gradient force and its effects. However, the vertical variation is especially significant, as it results from the pull of gravity on the fluid; namely, for the same given fluid, a decrease in elevation within it corresponds to a taller column of fluid weighing down on that point.