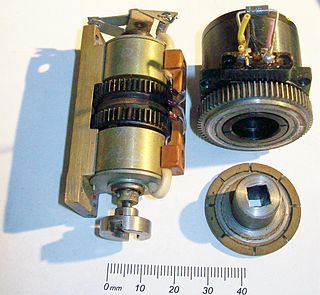

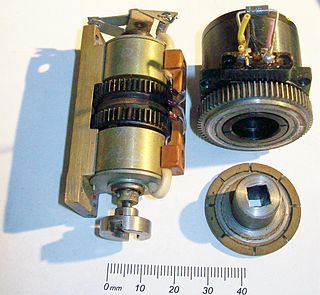

A clutch is a mechanical device that allows the output shaft to be disconnected from the rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

An automatic transmission is a multi-speed transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions. Vehicles with internal combustion engines, unlike electric vehicles, require the engine to operate in a narrow range of rates of rotation, requiring a gearbox, operated manually or automatically, to drive the wheels over a wide range of speeds.

A four-wheel drive, also called 4×4 or 4WD, is a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer case providing an additional output drive shaft and, in many instances, additional gear ranges.

A torque converter is a device, usually implemented as a type of fluid coupling, that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the torque converter connects the prime mover to the automatic gear train, which then drives the load. It is thus usually located between the engine's flexplate and the transmission. The equivalent device in a manual transmission is the mechanical clutch.

A transmission is a mechanical device which uses a gear set—two or more gears working together—to change the speed or direction of rotation in a machine. Many transmissions have multiple gear ratios, but there are also transmissions that use a single fixed-gear ratio.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

A manual transmission (MT), also known as manual gearbox, standard transmission, or stick shift, is a multi-speed motor vehicle transmission system, where gear changes require the driver to manually select the gears by operating a gear stick and clutch.

A limited-slip differential (LSD) is a type of differential gear train that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. Limited-slip differentials are often known by the generic trademark Positraction, a brand name owned by General Motors and originally used for its Chevrolet branded vehicles.

A semi-automatic transmission is a multiple-speed transmission where part of its operation is automated, but the driver's input is still required to launch the vehicle from a standstill and to manually change gears. Semi-automatic transmissions were almost exclusively used in motorcycles and are based on conventional manual transmissions or sequential manual transmissions, but use an automatic clutch system. But some semi-automatic transmissions have also been based on standard hydraulic automatic transmissions with torque converters and planetary gearsets.

Engine braking occurs when the retarding forces within an internal combustion engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes.

A direct-shift gearbox is an electronically controlled, dual-clutch, multiple-shaft, automatic gearbox, in either a transaxle or traditional transmission layout, with automated clutch operation, and with fully-automatic or semi-manual gear selection. The first dual-clutch transmissions were derived from Porsche in-house development for the Porsche 962 in the 1980s.

A preselector gearbox is a type of manual transmission mostly used on passenger cars and racing cars in the 1930s, in buses from 1940–1960 and in armoured vehicles from the 1930s to the 1970s. The defining characteristic of a preselector gearbox is that the gear shift lever allowed the driver to "pre-select" the next gear, usually with the transmission remaining in the current gear until the driver pressed the "gear change pedal" at the desired time.

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

A slipper clutch(also known as a back-torque limiter) is a specialized clutch with an integrated freewheel mechanism, developed for performance-oriented motorcycles to mitigate the effects of engine braking when riders decelerate.

A transmission control unit (TCU), also known as a transmission control module (TCM), or a gearbox control unit (GCU), is a type of automotive ECU that is used to control electronic automatic transmissions. Similar systems are used in conjunction with various semi-automatic transmissions, purely for clutch automation and actuation. A TCU in a modern automatic transmission generally uses sensors from the vehicle, as well as data provided by the engine control unit (ECU), to calculate how and when to change gears in the vehicle for optimum performance, fuel economy and shift quality.

A centrifugal clutch is an automatic clutch that uses centrifugal force to operate. The output shaft is disengaged at lower rotational speed and engages as the output increases to a certain speed. It is often used in mopeds, underbones, lawn mowers, go-karts, chainsaws, mini bikes, and some paramotors and boats to keep the engine from stalling when the output shaft is slowed or stopped abruptly, and to remove load when starting and idling. It has been superseded for automobile applications by the fluid coupling, torque converter and automated manual transmissions.

Electromagnetic clutches operate electrically but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches. Over the years, EM became known as electromagnetic versus electro-mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and clutch designs has increased dramatically, but the basic operation remains the same today.

Twin Clutch SST is the brand name of a six-speed dual-clutch automatic transmission, developed by Getrag for Mitsubishi Motors. The system was first incorporated in the 2008 Lancer Evolution X, and was designed to be a more performance-oriented system than that developed by rival manufacturers, with shorter gear ratios optimized for acceleration.

A dual-clutch transmission (DCT) is a type of multi-speed vehicle transmission system, that uses two separate clutches for odd and even gear sets. The design is often similar to two separate manual transmissions with their respective clutches contained within one housing, and working as one unit. In car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears.

A motorcycle transmission is a transmission created specifically for motorcycle applications. They may also be found in use on other light vehicles such as motor tricycles and quadbikes, go-karts, offroad buggies, auto rickshaws, mowers, and other utility vehicles, microcars, and even some superlight racing cars.