Related Research Articles

Lithography is a planographic method of printing originally based on the immiscibility of oil and water. The printing is from a stone or a metal plate with a smooth surface. It was invented in 1796 by the German author and actor Alois Senefelder and was initially used mostly for musical scores and maps. Lithography can be used to print text or images onto paper or other suitable material. A lithograph is something printed by lithography, but this term is only used for fine art prints and some other, mostly older, types of printed matter, not for those made by modern commercial lithography.

A blueprint is a reproduction of a technical drawing or engineering drawing using a contact print process on light-sensitive sheets introduced by Sir John Herschel in 1842. The process allowed rapid and accurate production of an unlimited number of copies. It was widely used for over a century for the reproduction of specification drawings used in construction and industry. Blueprints were characterized by white lines on a blue background, a negative of the original. Color or shades of grey could not be reproduced.

The collodion process is an early photographic process. The collodion process, mostly synonymous with the "collodion wet plate process", requires the photographic material to be coated, sensitized, exposed, and developed within the span of about fifteen minutes, necessitating a portable darkroom for use in the field. Collodion is normally used in its wet form, but it can also be used in its dry form, at the cost of greatly increased exposure time. The increased exposure time made the dry form unsuitable for the usual portraiture work of most professional photographers of the 19th century. The use of the dry form was mostly confined to landscape photography and other special applications where minutes-long exposure times were tolerable.

The albumen print, also called albumen silver print, is a method of producing a photographic print using egg whites. Published in January 1847 by Louis Désiré Blanquart-Evrard, it was the first commercial process of producing a photo on a paper base from a negative, previous methods - such as the daguerreotype and the tintype - having been printed on metal. It became the dominant form of photographic positives from 1855 to the start of the 20th century, with a peak in the 1860–90 period. During the mid-19th century, the carte de visite became one of the more popular uses of the albumen method. In the 19th century, E. & H. T. Anthony & Company were the largest makers and distributors of albumen photographic prints and paper in the United States.

Color photography is photography that uses media capable of capturing and reproducing colors. By contrast, black-and-white or gray-monochrome photography records only a single channel of luminance (brightness) and uses media capable only of showing shades of gray.

Within the commercial printing industry, the job of stripping involves arranging and joining film negatives as part of the process of preparing printing plates. In the UK, the same operation is termed "planning" and film positives are used, rather than the negatives in the USA. Because the industry has largely moved to digital processes, the job of stripping, or planning has become rare or even obsolete.

The gelatin silver print is the most commonly used chemical process in black-and-white photography, and is the fundamental chemical process for modern analog color photography. As such, films and printing papers available for analog photography rarely rely on any other chemical process to record an image. A suspension of silver salts in gelatin is coated onto a support such as glass, flexible plastic or film, baryta paper, or resin-coated paper. These light-sensitive materials are stable under normal keeping conditions and are able to be exposed and processed even many years after their manufacture. The "dry plate" gelatin process was an improvement on the collodion wet-plate process dominant from the 1850s–1880s, which had to be exposed and developed immediately after coating.

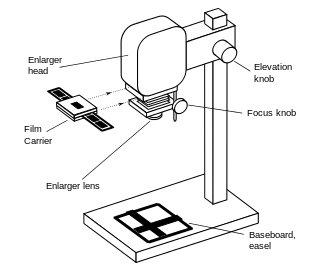

An enlarger is a specialized transparency projector used to produce photographic prints from film or glass negatives, or from transparencies.

A contact print is a photographic image produced from film; sometimes from a film negative, and sometimes from a film positive or paper negative. In a darkroom an exposed and developed piece of film or photographic paper is placed emulsion side down, in contact with a piece of photographic paper, light is briefly shone through the negative or paper and then the paper is developed to reveal the final print.

Photographic printing is the process of producing a final image on paper for viewing, using chemically sensitized paper. The paper is exposed to a photographic negative, a positive transparency , or a digital image file projected using an enlarger or digital exposure unit such as a LightJet or Minilab printer. Alternatively, the negative or transparency may be placed atop the paper and directly exposed, creating a contact print. Digital photographs are commonly printed on plain paper, for example by a color printer, but this is not considered "photographic printing".

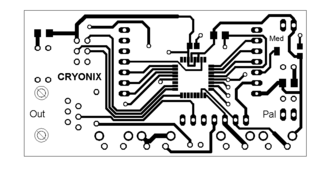

Photoengraving is a process that uses a light-sensitive photoresist applied to the surface to be engraved to create a mask that protects some areas during a subsequent operation which etches, dissolves, or otherwise removes some or all of the material from the unshielded areas of a substrate. Normally applied to metal, it can also be used on glass, plastic and other materials.

Whiteprint describes a document reproduction produced by using the diazo chemical process. It is also known as the blue-line process since the result is blue lines on a white background. It is a contact printing process that accurately reproduces the original in size, but cannot reproduce continuous tones or colors. The light sensitivity of the chemicals used was known in the 1890s and several related printing processes were patented at that time. Whiteprinting replaced the blueprint process for reproducing architectural and engineering drawings because the process was simpler and involved fewer toxic chemicals. A blue-line print is not permanent and will fade if exposed to light for weeks or months, but a drawing print that lasts only a few months is sufficient for many purposes.

A latent image is an invisible image produced by the exposure to light of a photosensitive material such as photographic film. When photographic film is developed, the area that was exposed darkens and forms a visible image. In the early days of photography, the nature of the invisible change in the silver halide crystals of the film's emulsion coating was unknown, so the image was said to be "latent" until the film was treated with photographic developer.

Sun printing may refer to various printing techniques which use sunlight as a developing or fixative agent.

Gum printing is a way of making photographic reproductions without the use of silver halides. The process uses salts of dichromate in common with a number of other related processes such as sun printing.

Architectural reprography, the reprography of architectural drawings, covers a variety of technologies, media, and supports typically used to make multiple copies of original technical drawings and related records created by architects, landscape architects, engineers, surveyors, mapmakers and other professionals in building and engineering trades.

Photographic film is a strip or sheet of transparent film base coated on one side with a gelatin emulsion containing microscopically small light-sensitive silver halide crystals. The sizes and other characteristics of the crystals determine the sensitivity, contrast, and resolution of the film. Film is typically segmented in frames, that give rise to separate photographs.

A heliographic copier or heliographic duplicator is an apparatus used in the world of reprography for making contact prints on paper from original drawings made with that purpose on tracing paper, parchment paper or any other transparent or translucent material using different procedures. In general terms some type of heliographic copier is used for making: Hectographic prints, Ferrogallic prints, Gel-lithographs or Silver halide prints. All of them, until a certain size, can be achieved using a contact printer with an appropriate lamp but for big engineering and architectural plans, the heliographic copiers used with the cyanotype and the diazotype technologies, are of the roller type, which makes them completely different from contact printers.

A photolith film is a transparent film, made with some sort of transparent plastic. Nowadays, with the use of laser printers and computers, the photolith film can be based on polyester, vegetable paper or laser film paper. It is mainly used in all photolithography processes.

A thermal copier or thermocopier is a kind of photocopier based on the effect of heat. The original sheet feeds in conjunction with the "thermo-sensitive" paper, generating a copy on its specially treated surface. The black parts on the original sheet, once scanned, make the copier activate the heating elements that produce some chemical reactions on the "thermo-sensitive" copy paper that darkens its surface. After the process, a stable black-and-white image is obtained on the cooled film or paper.

References

- 1 2 Cryder, George R. (November 1948). "Contact". Popular Mechanics. Hearst Magazines. pp. 216–. ISSN 0032-4558.

- ↑ Eva Zeisel; Robert Sabella (2006). Blueprints replaced by whiteprints. Que Certification. pp. 244–. ISBN 978-0-7897-3504-1.

- ↑ NIIR board (1 October 2002). Hand Book on Printing Technology (offset, Gravure, Flexo, Screen). National Institute Of Industrial Research. pp. 222–. ISBN 978-81-7833-087-7.