Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.25 millimetres (0.01 in) thick.

Flexography is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress, evolved with high speed rotary functionality, which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper. It is widely used for printing on the non-porous substrates required for various types of food packaging.

A paper machine is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

Rotogravure is a type of intaglio printing process, which involves engraving the image onto an image carrier. In gravure printing, the image is engraved onto a cylinder because, like offset printing and flexography, it uses a rotary printing press.

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is vacuum forming.

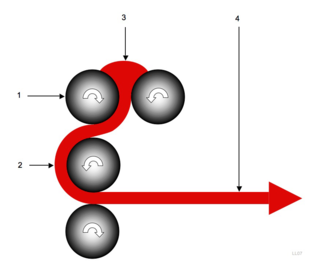

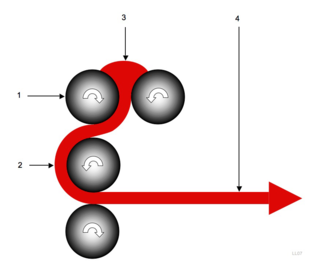

A calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes misspelled calendars.

Avery Dennison Corporation is a multinational manufacturer and distributor of pressure-sensitive adhesive materials, apparel branding labels and tags, RFID inlays, and specialty medical products. The company is a member of the Fortune 500 and is headquartered in Mentor, Ohio.

Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fibre, foil, cloth, paper, corrugated fibreboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal. In the metalworking and leather industries, the process is known as clicking and the machine may be referred to as a clicking machine. When a dinking die or dinking machine is used, the process is known as dinking. Commonly produced items using this process include gaskets, labels, tokens, corrugated boxes, and envelopes.

Laminated object manufacturing (LOM) is a rapid prototyping system developed by Helisys Inc. In it, layers of adhesive-coated paper, plastic, or metal laminates are successively glued together and cut to shape with a knife or laser cutter. Objects printed with this technique may be additionally modified by machining or drilling after printing. Typical layer resolution for this process is defined by the material feedstock and usually ranges in thickness from one to a few sheets of copy paper.

A web is a long, thin, and flexible material. Common webs include foil, metal, paper, textile, plastic film, and wire. Common processes carried out on webs include coating, plating, and laminating.

Converting was a trade publication and Website owned by Reed Business Information serving the information needs of converters: industries that convert paper, paperboard, plastic film and foil materials into finished, printed packaging such as bags, pouches, labels, tags, folding cartons and corrugated shipping cases.

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

A winding machine or winder is a machine for wrapping string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

Topflight Corporation is a manufacturer of printed labels and die-cut components. Topflight is ISO 9001:2008 and ISO 13485:2003 certified and is one of the oldest privately owned label companies. Topflight creates products for varying industries: Medical Devices, Pharmaceutical, Consumer & Durable Goods, Cosmetic & Personal Care, Electronics, Tire and Automotive. Based on annual sales of printed and converted labels, Topflight is ranked number 21 on the Top Tag and Label Converters list.

Plastic film is a thin continuous polymeric material. Thicker plastic material is often called a "sheet". These thin plastic membranes are used to separate areas or volumes, to hold items, to act as barriers, or as printable surfaces.

Web-guiding systems are used in the converting industry to position flat materials, known as webs, before processing. They are typically positioned just before a critical stage on a converting machine. Each type of web guiding system uses a sensor to monitor the web position for lateral tracking, and each has an actuator to shift the running web mechanically back on course whenever the sensor detects movement away from the set path. Actuators may be pneumatic or hydraulic cylinders, or some kind of electromechanical device. Because the web may be fragile — particularly at its edge — non-contact sensors are used. These sensors may be pneumatic, photoelectric, ultrasonic, or infrared. The system’s controls must put the output signals from the sensors in to a form that can drive the actuator.

A rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage and a rotating part to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants. A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union,rotorseal, rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union

SDM Strength Film known by the processing names Cross-Laminated Films and Strength Films, is a kind of High Density Polyethylene (HDPE) Cross Laminated Strength Film. Because of proprietary cross-laminated process, SDM Strength Film is very strong and find many application.