Corrugated fiberboard, corrugated cardboard, or corrugated is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.25 millimetres (0.01 in) thick.

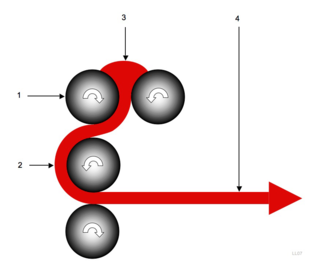

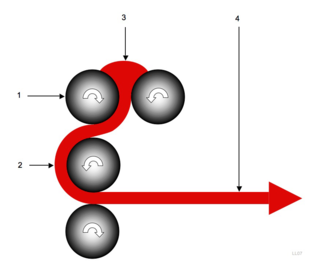

In the field of electronic devices, roll-to-roll processing, also known as web processing, reel-to-reel processing or R2R, is the process of creating electronic devices on a roll of flexible plastic, metal foil, or flexible glass. In other fields predating this use, it can refer to any process of applying coating, printing, or performing other processes starting with a roll of a flexible material and re-reeling after the process to create an output roll. These processes, and others such as sheeting, can be grouped together under the general term converting. When the rolls of material have been coated, laminated or printed they can be subsequently slit to their finished size on a slitter rewinder.

A paper machine is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

A calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes misspelled calendars.

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot with force sufficient to create plastic deformation.

A coating is a covering that is applied to the surface of an object, or substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. powder coatings.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

Corona treatment is a surface modification technique that uses a low temperature corona discharge plasma to impart changes in the properties of a surface. The corona plasma is generated by the application of high voltage to an electrode that has a sharp tip. The plasma forms at the tip. A linear array of electrodes is often used to create a curtain of corona plasma. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermosetting polymer. It is usually used to create a thick, tough finish that is more durable than conventional paint. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and medium-density fibreboard (MDF) to be powder coated, as little heat or oven dwell time is required to process them.

An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity. Static charge may be generated by the triboelectric effect or by a non-contact process using a high voltage power source. Static charge may be introduced on a surface as part of an in-mold label printing process.

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages.

Coated paper is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absorbency. Various materials, including kaolinite, calcium carbonate, bentonite, and talc, can be used to coat paper for high-quality printing used in the packaging industry and in magazines.

Iran Electronics Industries or Integrated Electronics Industries(IEI, Persian: صنایع الکترونیک ایران; also known as Persian: صاایران, Sâiran) is a state-owned subsidiary of Iran's Ministry of Defense. It is a diversified organization with operations in electronics, optics, electro-optics, medical equipment, communications, computer and semiconductors.

A converter is a company that specializes in modifying or combining raw materials such as polyesters, adhesives, silicone, adhesive tapes, foams, plastics, felts, rubbers, liners and metals, as well as other materials, to create new products.

Printed electronics is a set of printing methods used to create electrical devices on various substrates. Printing typically uses common printing equipment suitable for defining patterns on material, such as screen printing, flexography, gravure, offset lithography, and inkjet. By electronic-industry standards, these are low-cost processes. Electrically functional electronic or optical inks are deposited on the substrate, creating active or passive devices, such as thin film transistors; capacitors; coils; resistors. Some researchers expect printed electronics to facilitate widespread, very low-cost, low-performance electronics for applications such as flexible displays, smart labels, decorative and animated posters, and active clothing that do not require high performance.

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. It has been done in a variety of ways during the history of glass.

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

JSW Ispat Steel Ltd (JISL) was an Indian company with operations in iron, steel, mining, energy and infrastructure. It was set up as Nippon Denro Ispat Limited in May 1984 by founding chairman M. L. Mittal. It was listed on the Bombay Stock Exchange and National Stock Exchange of India until 2013 when it was merged with JSW Steel. It was headquartered in Mumbai and employed about 3,000 people.

Slot-die coating is a coating technique for the application of solution, slurry, hot-melt, or extruded thin films onto typically flat substrates such as glass, metal, paper, fabric, plastic, or metal foils. The process was first developed for the industrial production of photographic papers in the 1950's. It has since become relevant in numerous commercial processes and nanomaterials related research fields.