Related Research Articles

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name petroleum covers both naturally occurring unprocessed crude oil and petroleum products that consist of refined crude oil. A fossil fuel, petroleum is formed when large quantities of dead organisms, mostly zooplankton and algae, are buried underneath sedimentary rock and subjected to both prolonged heat and pressure.

Naphtha is a flammable liquid hydrocarbon mixture. Generally, it is a fraction of crude oil, but it can also be produced from natural gas condensates, petroleum distillates, and the fractional distillation of coal tar and peat. In some industries and regions, the name naphtha refers to crude oil or refined petroleum products such as kerosene.

An oil refinery or petroleum refinery is an industrial process plant where petroleum is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemical feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day.

A refinery is a production facility composed of a group of chemical engineering unit processes and unit operations refining certain materials or converting raw material into products of value.

Fuel oil is any of various fractions obtained from the distillation of petroleum. Such oils include distillates and residues. Fuel oils include heavy fuel oil, marine fuel oil (MFO), furnace oil (FO), gas oil (gasoil), heating oils, diesel fuel and others.

A visbreaker is a processing unit in an oil refinery whose purpose is to reduce the quantity of residual oil produced in the distillation of crude oil and to increase the yield of more valuable middle distillates by the refinery. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons.. The process name of "visbreaker" refers to the fact that the process reduces the viscosity of the residual oil. The process is non-catalytic.

Petroleum products are materials derived from crude oil (petroleum) as it is processed in oil refineries. Unlike petrochemicals, which are a collection of well-defined usually pure organic compounds, petroleum products are complex mixtures. Most petroleum is converted into petroleum products, which include several classes of fuels.

A fraction in chemistry is a quantity collected from a batch of a substance in a fractionating separation process. In such a process, a mixture is separated into fractions, which have compositions that vary according to a gradient. A fraction can be defined as a group of chemicals that have similar boiling points. A common fractionating process is fractional distillation. It is used to produce liquor and various hydrocarbon fuels, such as gasoline, kerosene and diesel.

Bonny Light oil was found at Oloibiri in the Niger delta region of Nigeria in 1956 for its commercial use.. Due to its features of generating high profit, it is highly demanded by refiners. Bonny light oil has an API of 32.9, classified as light oil. It is regarded as more valuable than the other oils with lower API as more high-value products are produced in the refinement. However, in Nigeria, problems due to oil spillage caused by vandalism, affects both human and the ecosystem in detrimental ways. Some experiments on animals and soil are done to figure out those impacts on organisms.

Sour crude oil is crude oil containing a high amount of the impurity sulfur. It is common to find crude oil containing some impurities. When the total sulfur level in the oil is more than 0.5%, the oil is called "sour".

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

An oil terminal is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other storage facilities. An oil terminal typically has a variety of above or below ground tankage; facilities for inter-tank transfer; pumping facilities; loading gantries for filling road tankers or barges; ship loading/unloading equipment at marine terminals; and pipeline connections.

Metal deactivators, or metal deactivating agents (MDA) are fuel additives and oil additives used to stabilize fluids by deactivating metal ions, mostly introduced by the action of naturally occurring acids in the fuel and acids generated in lubricants by oxidative processes with the metallic parts of the systems. Fuels desulfurized by copper sweetening also contain a significant trace amounts of copper.

Merox is an acronym for mercaptan oxidation. It is a proprietary catalytic chemical process developed by UOP used in oil refineries and natural gas processing plants to remove mercaptans from LPG, propane, butanes, light naphthas, kerosene and jet fuel by converting them to liquid hydrocarbon disulfides.

Onshore, when used in relation to hydrocarbons, refers to an oil, natural gas or condensate field that is under the land or to activities or operations carried out in relation to such a field.

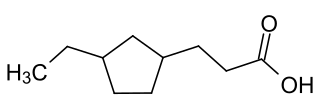

Naphthenic acid (NA) is a mixture of several cyclopentyl and cyclohexyl carboxylic acids with molecular weight of 120 to well over 700 atomic mass units. The main fraction are carboxylic acids with a carbon backbone of 9 to 20 carbons. McKee et al. claim that "naphthenic acids (NAs) are primarily cycloaliphatic carboxylic acids with 10 to 16 carbons"[1], although acids containing up to 50 carbons have been identified in heavy petroleum. The term naphthenic acid has roots in the somewhat archaic term "naphthene" used to classify hydrocarbons. It was originally used to describe the complex mixture of petroleum-based acids when the analytical methods available in the early 1900s could identify only a few naphthene-type components with accuracy. Today "naphthenic" acid is used in a more generic sense to refer to all of the carboxylic acids present in petroleum, whether cyclic, acyclic, or aromatic compounds, and carboxylic acids containing heteroatoms such as N and S. Although commercial naphthenic acids often contain a majority of cycloaliphatic acids, multiple studies have shown they also contain straight chain and branched aliphatic acids and aromatic acids; some naphthenic acids contain >50% combined aliphatic and aromatic acids.

The Jebel Ali refinery was constructed from 1996 to 1999. It is located in Dubai and operated by the Emirates National Oil Co. (ENOC), which is owned by the Government of Dubai. It is a 120 kbpd gas condensate refinery, and processes mainly condensate or light crude oil. These inputs are processed to various products, including LPG, naphtha, jet fuel, diesel oil and fuel oil. The plant consists of two 60 kbit/s condensate distillation units and five merox sweetening units.

The BPRefinery (Kent) was an oil refinery on the Isle of Grain in Kent. It was commissioned in 1953 and had a maximum processing capacity of 11 million tonnes of crude oil per year. It was decommissioned in August 1982.

Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

Copper naphthenate is the copper salt of naphthenic acid. Naphthenic acid is a term commonly used in the petroleum industry to collectively refer to all of the carboxylic acids naturally occurring in crude oil. Naphthenic acids are primarily cycloaliphatic carboxylic acids with 10 to 24 or more carbons, although substantial quantities of non-cyclic, aromatic and heteroatom- containing carboxylic acids are also present. Copper naphthenate is most widely used in wood preservation and for protecting other cellulosic materials such as textiles and cordage from damage by decay fungi and insects. Other metal naphthenates are used as paint driers, rubber adhesion promoters, lubricant additives, and catalysts where oil solubility is required.

References

- ↑ "Glossary of Terms".

- ↑ "linde copper sweetening". Archived from the original on July 14, 2011. Retrieved December 15, 2007.