Pier Luigi Nervi was an Italian engineer and architect. He studied at the University of Bologna graduating in 1913. Nervi taught as a professor of engineering at Rome University from 1946 to 1961 and is known worldwide as a structural engineer and architect and for his innovative use of reinforced concrete, especially with numerous notable thin shell structures worldwide.

Notre-Dame du Haut is a Roman Catholic chapel in Ronchamp, France. Built in 1955, it is one of the finest examples of the architecture of Franco-Swiss architect Le Corbusier. The chapel is a working religious building and is under the guardianship of the private foundation Association de l’Œuvre de Notre-Dame du Haut. It attracts 80,000 visitors each year. In 2016, it was inscribed on the UNESCO World Heritage List in along with sixteen other works by Le Corbusier, because of its importance to the development of modernist architecture.

The Guastavino tile arch system is a version of Catalan vault introduced to the United States in 1885 by Spanish architect and builder Rafael Guastavino (1842–1908). It was patented in the United States by Guastavino in 1892.

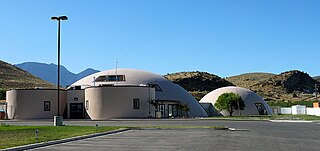

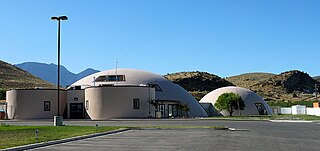

A monolithic dome is a thin-shell structure cast in a one-piece form. The form may be permanent or temporary and may or may not remain part of the finished structure. Monolithic domes are a form of monolithic architecture.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

Hyperboloid structures are architectural structures designed using a hyperboloid in one sheet. Often these are tall structures, such as towers, where the hyperboloid geometry's structural strength is used to support an object high above the ground. Hyperboloid geometry is often used for decorative effect as well as structural economy. The first hyperboloid structures were built by Russian engineer Vladimir Shukhov (1853–1939), including the Shukhov Tower in Polibino, Dankovsky District, Lipetsk Oblast, Russia.

Federation University Australia Gippsland Campus is an Australian university campus located in the town of Churchill 142 km east of Melbourne. Its main neighbouring towns in the region are Morwell and Traralgon. Formerly a branch of Monash University, on 1 January 2014 it became part of Federation University Australia. Study areas at the campus include Arts ; Business; Education; Information Technology; Nursing; Midwifery; Sport, Outdoor and Physical Education; Psychology; Science; Engineering and Visual Arts.

Béton brut is architectural concrete that is left unfinished after being cast, displaying the patterns and seams imprinted on it by the formwork. Béton brut is not a material itself, but rather a way of using concrete. The term comes from French and means "raw concrete".

The Gaussian vault is a reinforced masonry construction technique invented by Uruguayan engineer Eladio Dieste to efficiently and economically build thin-shell barrel vaults and wide curved roof spans that are resistant to buckling.

The history of construction traces the changes in building tools, methods, techniques and systems used in the field of construction. It explains the evolution of how humans created shelter and other structures that comprises the entire built environment. It covers several fields including structural engineering, civil engineering, city growth and population growth, which are relatives to branches of technology, science, history, and architecture. The fields allow both modern and ancient construction to be analyzed, as well as the structures, building materials, and tools used.

The history of structural engineering dates back to at least 2700 BC when the step pyramid for Pharaoh Djoser was built by Imhotep, the first architect in history known by name. Pyramids were the most common major structures built by ancient civilizations because it is a structural form which is inherently stable and can be almost infinitely scaled.

Binishells are reinforced concrete thin-shell structures that are lifted and shaped by air pressure. The original technology was invented in the 1960s by Dante Bini, who built 1,600 of them in 23 countries.

Capital Gate, also known as the Leaning Tower of Abu Dhabi, is a skyscraper in Abu Dhabi that is over 160 meters (520 ft) tall, 35 stories high, with over 16,000 square meters (170,000 sq ft) of usable office space. Capital Gate is one of the tallest buildings in the city and was designed to incline 18° west, more than four times the lean of the Leaning Tower of Pisa. The building is owned and was developed by the Abu Dhabi National Exhibitions Company. The tower is the focal point of Capital Centre.

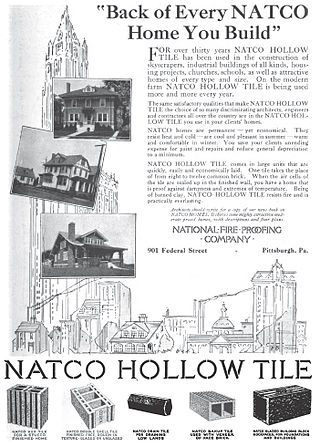

Structural clay tile describes a category of burned-clay building materials used to construct roofing, walls, and flooring for structural and non-structural purposes, especially in fireproofing applications. Also called building tile, structural terra cotta, hollow tile, saltillo tile, and clay block, the material is an extruded clay shape with substantial depth that allows it to be laid in the same manner as other clay or concrete masonry. In North America it was chiefly used during the late 19th and early 20th centuries, reaching peak popularity at the turn of the century and declining around the 1950s. Structural clay tile grew in popularity in the end of the nineteenth-century because it could be constructed faster, was lighter, and required simpler flat falsework than earlier brick vaulting construction.

Construction 3D Printing (c3Dp) or 3D construction Printing (3DCP) refers to various technologies that use 3D printing as a core method to fabricate buildings or construction components. Alternative terms for this process include "additive construction." "3D Concrete" refers to concrete extrusion technologies whereas Autonomous Robotic Construction System (ARCS), large-scale additive manufacturing (LSAM), and freeform construction (FC) refer to other sub-groups.

Domes were a characteristic element of the architecture of Ancient Rome and of its medieval continuation, the Byzantine Empire. They had widespread influence on contemporary and later styles, from Russian and Ottoman architecture to the Italian Renaissance and modern revivals. The domes were customarily hemispherical, although octagonal and segmented shapes are also known, and they developed in form, use, and structure over the centuries. Early examples rested directly on the rotunda walls of round rooms and featured a central oculus for ventilation and light. Pendentives became common in the Byzantine period, provided support for domes over square spaces.

Domes built in the 19th, 20th, and 21st centuries benefited from more efficient techniques for producing iron and steel as well as advances in structural analysis.

The reinforcement of 3D printed concrete is a mechanism where the ductility and tensile strength of printed concrete are improved using various reinforcing techniques, including reinforcing bars, meshes, fibers, or cables. The reinforcement of 3D printed concrete is important for the large-scale use of the new technology, like in the case of ordinary concrete. With a multitude of additive manufacturing application in the concrete construction industry—specifically the use of additively constructed concrete in the manufacture of structural concrete elements—the reinforcement and anchorage technologies vary significantly. Even for non-structural elements, the use of non-structural reinforcement such as fiber reinforcement is not uncommon. The lack of formwork in most 3D printed concrete makes the installation of reinforcement complicated. Early phases of research in concrete 3D printing primarily focused on developing the material technologies of the cementitious/concrete mixes. These causes combined with the non-existence of codal provisions on reinforcement and anchorage for printed elements speak for the limited awareness and the usage of the various reinforcement techniques in additive manufacturing. The material extrusion-based printing of concrete is currently favorable both in terms of availability of technology and of the cost-effectiveness. Therefore, most of the reinforcement techniques developed or currently under development are suitable to the extrusion-based 3D printing technology.

3D concrete printing, or simply concrete printing, refers to digital fabrication processes for cementitious materials based on one of several different 3D printing technologies. 3D-printed concrete eliminates the need for formwork, reducing material waste and allowing for greater geometric freedom in complex structures. With recent developments in mix design and 3D printing technology over the last decade, 3D concrete printing has grown exponentially since its emergence in the 1990s. Architectural and structural applications of 3D-printed concrete include the production of building blocks, building modules, street furniture, pedestrian bridges, and low-rise residential structures.