Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is a type of fossil fuel, formed when dead plant matter decays into peat which is converted into coal by the heat and pressure of deep burial over millions of years. Vast deposits of coal originate in former wetlands called coal forests that covered much of the Earth's tropical land areas during the late Carboniferous (Pennsylvanian) and Permian times.

In industrial chemistry, coal gasification is the process of producing syngas—a mixture consisting primarily of carbon monoxide (CO), hydrogen, carbon dioxide, methane, and water vapour —from coal and water, air and/or oxygen.

Coal pollution mitigation is a series of systems and technologies that seek to mitigate health and environmental impact of burning coal for energy. Burning coal releases harmful substances that contribute to air pollution, acid rain, and greenhouse gas emissions. Mitigation includes precombustion approaches, such as cleaning coal, and post combustion approaches, include flue-gas desulfurization, selective catalytic reduction, electrostatic precipitators, and fly ash reduction. These measures aim to reduce coal's impact on human health and the environment.

Underground coal gasification (UCG) is an industrial process which converts coal into product gas. UCG is an in-situ gasification process, carried out in non-mined coal seams using injection of oxidants and steam. The product gas is brought to the surface through production wells drilled from the surface.

Carbon capture and storage (CCS) is a process by which carbon dioxide (CO2) from industrial installations is separated before it is released into the atmosphere, then transported to a long-term storage location. The CO2 is captured from a large point source, such as a natural gas processing plant and is typically stored in a deep geological formation. Around 80% of the CO2 captured annually is used for enhanced oil recovery (EOR), a process by which CO2 is injected into partially-depleted oil reservoirs in order to extract more oil and then is largely left underground. Since EOR utilizes the CO2 in addition to storing it, CCS is also known as carbon capture, utilization, and storage (CCUS).

An integrated gasification combined cycle (IGCC) is a technology using a high pressure gasifier to turn coal and other carbon based fuels into pressurized gas—synthesis gas (syngas). It can then remove impurities from the syngas prior to the electricity generation cycle. Some of these pollutants, such as sulfur, can be turned into re-usable byproducts through the Claus process. This results in lower emissions of sulfur dioxide, particulates, mercury, and in some cases carbon dioxide. With additional process equipment, a water-gas shift reaction can increase gasification efficiency and reduce carbon monoxide emissions by converting it to carbon dioxide. The resulting carbon dioxide from the shift reaction can be separated, compressed, and stored through sequestration. Excess heat from the primary combustion and syngas fired generation is then passed to a steam cycle, similar to a combined cycle gas turbine. This process results in improved thermodynamic efficiency, compared to conventional pulverized coal combustion.

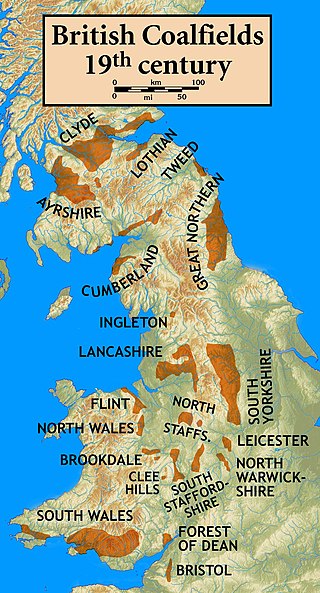

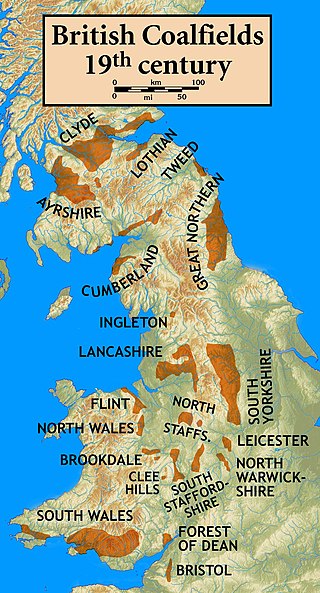

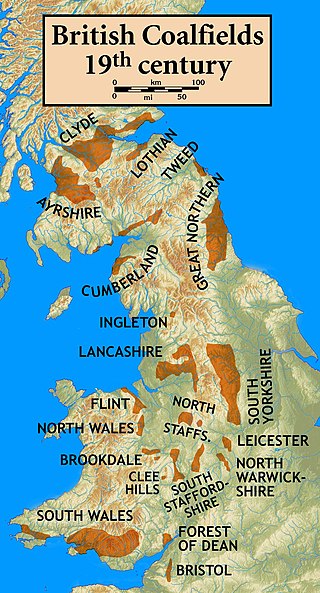

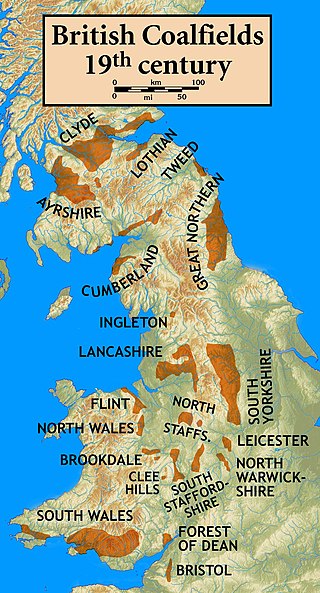

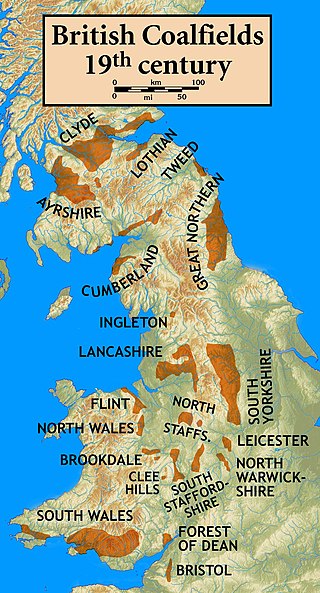

The South Yorkshire Coalfield is so named from its position within Yorkshire. It covers most of South Yorkshire, West Yorkshire and a small part of North Yorkshire. The exposed coalfield outcrops in the Pennine foothills and dips under Permian rocks in the east. Its most famous coal seam is the Barnsley Bed. Coal has been mined from shallow seams and outcrops since medieval times and possibly earlier.

Carbon capture and storage (CCS) is a technology that can capture carbon dioxide CO2 emissions produced from fossil fuels in electricity, industrial processes which prevents CO2 from entering the atmosphere. Carbon capture and storage is also used to sequester CO2 filtered out of natural gas from certain natural gas fields. While typically the CO2 has no value after being stored, Enhanced Oil Recovery uses CO2 to increase yield from declining oil fields.

The milestones for carbon capture and storage show the lack of commercial scale development and implementation of CCS over the years since the first carbon tax was imposed.

Bioenergy with carbon capture and storage (BECCS) is the process of extracting bioenergy from biomass and capturing and storing the carbon dioxide (CO2) that is produced.

Eston Grange Power Station was a proposed power station to be situated near to Eston in Redcar and Cleveland. If built, it would have been the UK's first pre-combustion carbon capture and storage (CCS) plant. The station could have generated up to 850 megawatts of electricity, enough to supply around a million people with electricity. The station would use standard oil refinery technology to turn gasified coal into hydrogen and carbon dioxide.

Coal mining in the United Kingdom dates back to Roman times and occurred in many different parts of the country. Britain's coalfields are associated with Northumberland and Durham, North and South Wales, Yorkshire, the Scottish Central Belt, Lancashire, Cumbria, the East and West Midlands and Kent. After 1972, coal mining quickly collapsed and had practically disappeared by the 21st century. The consumption of coal—mostly for electricity—fell from 157 million tonnes in 1970 to just 587,000 tonnes in 2023. Employment in coal mines fell from a peak of 1,191,000 in 1920 to 695,000 in 1956, 247,000 in 1976, 44,000 in 1993, 2,000 in 2015, and to 360 in 2022.

Hi-Gen Power was a London-based developer of projects combining underground coal gasification with carbon capture and storage and alkaline fuel cells. It was established in 2009 to commercialize alkaline fuel cells developed by the fuel cell manufacturer AFC Energy. It is affiliated with B9 Gas.

The Northumberland Coalfield is a coalfield in north-east England. It is continuous with the Durham Coalfield to its south. It extends from Shilbottle in the north to the boundary with County Durham along the River Tyne in the south, beyond which is the Durham Coalfield.

The Cumberland Coalfield is a coalfield in Cumbria, north-west England. It extends from Whitehaven in the south to Maryport and Aspatria in the north.

The Lancashire Coalfield in North West England was an important British coalfield. Its coal seams were formed from the vegetation of tropical swampy forests in the Carboniferous period over 300 million years ago.

The Midgeholme Coalfield is a coalfield in Midgeholme, on the border of Cumbria with Northumberland in northern England. It is the largest of a series of small coalfields along the south side of the Tyne Valley and which are intermediate between the Northumberland and Durham Coalfields to the east and the Cumberland Coalfield to the west. Like the other small coalfields to its east, this small outlier of the Coal Measures at Midgeholme occurs on the Stublick-Ninety Fathom Fault System, a zone of faults defining the northern edge of the Alston Block otherwise known as the North Pennines. It is recorded that coal was being mined at Midgeholme in the early seventeenth century. In the 1830s coal trains were being hauled from Midgeholme Colliery along the Brampton Railway by Stephenson's Rocket. The early workings have left a legacy of spoil heaps, bell pits, shafts and adits. There is no current coal production. However in January 2014, Northumberland County Council gave planning permission for the open-cast extraction of 37,000 tonnes of coal at Halton Lea Gate. This may open the way for other applications to mine the coalfield. In 1990 a proposal to mine reserves of 60,000 tonnes of good-quality coal at Lambley, Northumberland was rejected, but the prospect for a successful application has now changed, since the Planning Inspector allowed the development to proceed at Halton Lea Gate on appeal.

The North East of England Process Industry Cluster (NEPIC) is an economic cluster developed in accordance with Michael Porter's theories and strategies regarding industrial clusters. The chemistry-using sectors in North East England, where more than 1,400 businesses are headquartered in the industry's supply chain, formed this Process Industry Cluster. In the north-east of England, the industry employs approximately 35,000 direct workers and around 190,000 indirect workers, who collectively account for more than one-third of the area's industrial economy. Companies in the cluster produce 35% of the pharmaceuticals and 50% of the petrochemicals used in the UK, making this area the only net exporter of goods from the country. The area has more than £13 billion in exports.

The geology of Northumberland in northeast England includes a mix of sedimentary, intrusive and extrusive igneous rocks from the Palaeozoic and Cenozoic eras. Devonian age volcanic rocks and a granite pluton form the Cheviot massif. The geology of the rest of the county is characterised largely by a thick sequence of sedimentary rocks of Carboniferous age. These are intruded by both Permian and Palaeogene dykes and sills and the whole is overlain by unconsolidated sediments from the last ice age and the post-glacial period. The Whin Sill makes a significant impact on Northumberland's character and the former working of the Northumberland Coalfield significantly influenced the development of the county's economy. The county's geology contributes to a series of significant landscape features around which the Northumberland National Park was designated.