A carbon sink is a natural or artificial reservoir that accumulates and stores some carbon-containing chemical compound for an indefinite period. The process by which carbon sinks remove carbon dioxide (CO

2) from the atmosphere is known as carbon sequestration. Public awareness of the significance of CO2 sinks has grown since passage of the Kyoto Protocol, which promotes their use as a form of carbon offset. There are also different strategies used to enhance this process.

Coalbed methane extraction is a method for extracting methane from a coal deposit.

The National Energy Technology Laboratory (NETL) is a U.S. national laboratory under the Department of Energy Office of Fossil Energy. NETL focuses on applied research for the clean production and use of domestic energy resources. NETL performs research and development on the supply, efficiency, and environmental constraints of producing and using fossil energy resources, while maintaining their affordability.

Coal pollution mitigation, often (incorrectly) called clean coal, is a series of systems and technologies that seek to mitigate the pollution and other environmental effects normally associated with the burning of coal, which is widely regarded as the dirtiest of the common fuels for industrial processes and power generation.

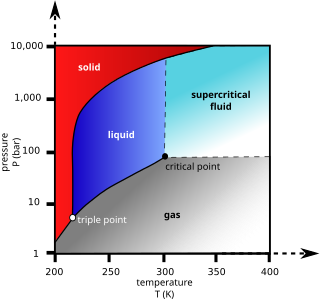

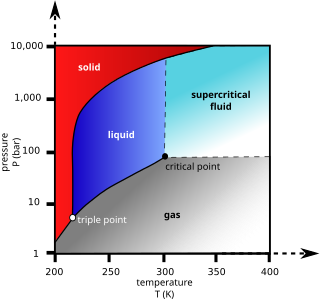

Supercritical carbon dioxide is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Carbon capture and storage (CCS) is the process of capturing waste carbon dioxide from large point sources, such as biomass or fossil fuel power plants, transporting it to a storage site, and depositing it where it will not enter the atmosphere, normally an underground geological formation. The aim is to prevent the release of large quantities of CO

2 into the atmosphere. It is a potential means of mitigating the contribution of fossil fuel emissions to global warming and ocean acidification. Although CO

2 has been injected into geological formations for several decades for various purposes, including enhanced oil recovery, the long term storage of CO

2 is a relatively new concept. The first commercial example was the Weyburn-Midale Carbon Dioxide Project in 2000. Another example is SaskPower's Boundary Dam. 'CCS' can also be used to describe the scrubbing of CO

2 from ambient air as a climate engineering technique.

Carbon sequestration is the process involved in carbon capture and the long-term storage of atmospheric carbon dioxide or other forms of carbon to mitigate or defer global warming. It has been proposed as a way to slow the atmospheric and marine accumulation of greenhouse gases, which are released by burning fossil fuels.

Clean coal technology is a collection of technologies being developed in attempts to lessen the negative environmental impact of coal energy generation and to mitigate worldwide climate change. When coal is used as a fuel source, the gaseous emissions generated by the thermal decomposition of the coal include sulfur dioxide (SO2), nitrogen oxides (NOx), mercury, and other chemical byproducts that vary depending on the type of the coal being used. These emissions have been established to have a negative impact on the environment and human health, contributing to acid rain, lung cancer and cardiovascular disease. As a result, clean coal technologies are being developed to remove or reduce pollutant emissions to the atmosphere. Some of the techniques that would be used to accomplish this include chemically washing minerals and impurities from the coal, gasification (see also IGCC), improved technology for treating flue gases to remove pollutants to increasingly stringent levels and at higher efficiency, carbon capture and storage technologies to capture the carbon dioxide from the flue gas and dewatering lower rank coals (brown coals) to improve the calorific value, and thus the efficiency of the conversion into electricity. Concerns exist regarding the economic viability of these technologies and the timeframe of delivery, potentially high hidden economic costs in terms of social and environmental damage, and the costs and viability of disposing of removed carbon and other toxic matter.

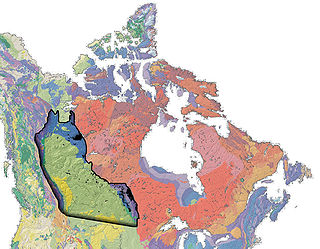

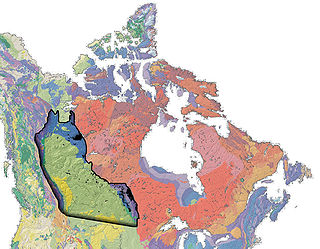

The Western Canadian Sedimentary Basin (WCSB) is a vast sedimentary basin underlying 1,400,000 square kilometres (540,000 sq mi) of Western Canada including southwestern Manitoba, southern Saskatchewan, Alberta, northeastern British Columbia and the southwest corner of the Northwest Territories. It consists of a massive wedge of sedimentary rock extending from the Rocky Mountains in the west to the Canadian Shield in the east. This wedge is about 6 kilometres (3.7 mi) thick under the Rocky Mountains, but thins to zero at its eastern margins. The WCSB contains one of the world's largest reserves of petroleum and natural gas and supplies much of the North American market, producing more than 16,000,000,000 cubic feet (450,000,000 m3) per day of gas in 2000. It also has huge reserves of coal. Of the provinces and territories within the WCSB, Alberta has most of the oil and gas reserves and almost all of the oil sands.

A carbon dioxide scrubber is a piece of equipment that absorbs carbon dioxide (CO2). It is used to treat exhaust gases from industrial plants or from exhaled air in life support systems such as rebreathers or in spacecraft, submersible craft or airtight chambers. Carbon dioxide scrubbers are also used in controlled atmosphere (CA) storage. They have also been researched for carbon capture as a means of combating global warming.

Methanation is the conversion of COx to methane CH4 through hydrogenation. The methanation reactions of COx were first discovered by Sabatier and Senderens in 1902.

Greenhouse gas removal projects are a type of climate engineering that seek to remove greenhouse gases from the atmosphere, and thus they tackle the root cause of global warming. These techniques either directly remove greenhouse gases, or alternatively seek to influence natural processes to remove greenhouse gases indirectly. The discipline overlaps with carbon capture and storage and carbon sequestration, and some projects listed may not be considered to be climate engineering by all commentators, instead being described as mitigation.

The milestones for carbon capture and storage show the lack of commercial scale development and implementation of CCS over the years since the first carbon tax was imposed.

Hydromethanation, [hahy-droh- meth-uh-ney-shuhn] is the process by which methane is produced through the combination of steam, carbonaceous solids and a catalyst in a fluidized bed reactor. The process, developed over the past 60 years by multiple research groups, enables the highly efficient conversion of coal, petroleum coke and biomass into clean, pipeline quality methane.

The Centre for Research into Earth Energy Systems is a Geo-Energy research centre at Durham University. The centre was formed in January 2006, and since then has won a research income of £1.3M per annum. The current Director of CeREES is Professor Jon Gluyas, co-author of textbook Petroleum Geoscience. The Centre is part of the multidisciplinary Durham Energy Institute. CeREES is one of only three academic members of the Carbon Capture and Storage Association and is also a member of the Underground Coal Gasification Association.

The Zonguldak basin of North Western Turkey has been mined for coal since the late 1800s. The basin takes its name after Zonguldak, Turkey, and is approximately 41° N. The Zonguldak basin is the only basin in Turkey with minable coal deposits. Geographically, the Zonguldak is roughly elliptical in shape with its long axis oriented roughly SW – NE, and is adjacent to the Black Sea. Three main regions have been recognized in the Zonguldak basin. These are the Armutcuk, the Zonguldak, and the Amasra from west to east respectively.

Lower-temperature fuel cell types such as the proton exchange membrane fuel cell, phosphoric acid fuel cell, and alkaline fuel cell require pure hydrogen as fuel, typically produced from external reforming of natural gas. However, fuels cells operating at high temperature such as the solid oxide fuel cell (SOFC) are not poisoned by carbon monoxide and carbon dioxide, and in fact can accept hydrogen, carbon monoxide, carbon dioxide, steam, and methane mixtures as fuel directly, because of their internal shift and reforming capabilities. This opens up the possibility of efficient fuel cell-based power cycles consuming solid fuels such as coal and biomass, the gasification of which results in syngas containing mostly hydrogen, carbon monoxide and methane which can be cleaned and fed directly to the SOFCs without the added cost and complexity of methane reforming, water gas shifting and hydrogen separation operations which would otherwise be needed to isolate pure hydrogen as fuel. A power cycle based on gasification of solid fuel and SOFCs is called an Integrated Gasification Fuel Cell (IGFC) cycle; the IGFC power plant is analogous to an integrated gasification combined cycle power plant, but with the gas turbine power generation unit replaced with a fuel cell power generation unit. By taking advantage of intrinsically high energy efficiency of SOFCs and process integration, exceptionally high power plant efficiencies are possible. Furthermore, SOFCs in the IGFC cycle can be operated so as to isolate a carbon dioxide-rich anodic exhaust stream, allowing efficient carbon capture to address greenhouse gas emissions concerns of coal-based power generation.

The Petra Nova project is a coal-energy-sector/ clean-energy project designed to reduce carbon emissions from one of the boilers of a coal burning power plant in Thompsons, Texas. It is a multi-million dollar project taken up by NRG Energy and JX Nippon Oil to retrofit one of the boilers at their WA Parish Generating Station with a post-combustion carbon capture treatment system to treat a portion of the atmospheric exhaust emissions from the retrofitted boiler. The plant entered commercial service in 1977, and the new carbon emissions reduction system was first put into operation on January 10, 2017. The project is designed to annually capture approximately 33% of the carbon dioxide emissions from the plant's boiler #8.