An explosive is a reactive substance that contains a great amount of potential energy that can produce an explosion if released suddenly, usually accompanied by the production of light, heat, sound, and pressure. An explosive charge is a measured quantity of explosive material, which may either be composed solely of one ingredient or be a mixture containing at least two substances.

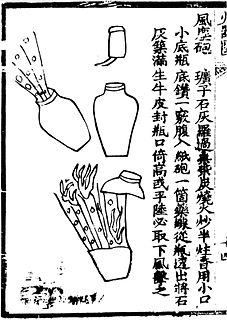

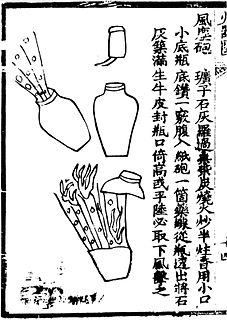

A bomb is an explosive weapon that uses the exothermic reaction of an explosive material to provide an extremely sudden and violent release of energy. Detonations inflict damage principally through ground- and atmosphere-transmitted mechanical stress, the impact and penetration of pressure-driven projectiles, pressure damage, and explosion-generated effects. Bombs have been utilized since the 11th century starting in East Asia.

Coal dust is a fine powdered form of which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling coal. It is a form of fugitive dust.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations could provide an ignition source, due to electrical arcing, or high temperature. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Mixtures of dispersed combustible materials and oxygen in the air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to as flammability limits or explosive limits. Combustion can range in violence from deflagration through detonation.

The ATEX directives are two EU directives describing the minimum safety requirements for workplaces and equipment used in explosive atmospheres. The name is an initialisation of the French term Appareils destinés à être utilisés en ATmosphères EXplosives.

A combustible material is something that can combust (burn) in air. Flammable materials are combustible materials that ignite easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame.

An explosion vent or rupture panel is a safety device to protect equipment or buildings against excessive internal, explosion-incurred pressures, by means of pressure relief. An explosion vent will relieve pressure from the instant its opening pressure pstat has been exceeded.

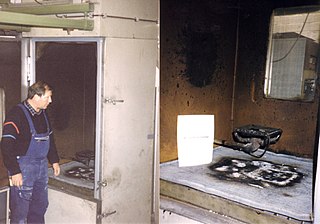

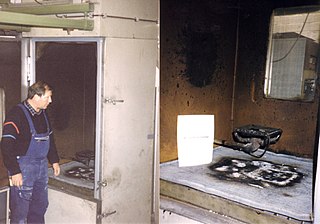

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

A rupture disk, also known as a pressure safety disc, burst disc, bursting disc, or burst diaphragm, is a non-reclosing pressure relief safety device that, in most uses, protects a pressure vessel, equipment or system from overpressurization or potentially damaging vacuum conditions.

The Institute for Occupational Safety and Health of the German Social Accident Insurance is a German institute located in Sankt Augustin near Bonn and is a main department of the German Social Accident Insurance. Belonging to the Statutory Accident Insurance means that IFA is a non-profit institution.

A flame arrester, deflagration arrester, or flame trap is a device that stops fuel combustion by extinguishing the flame.

The T2 Laboratories explosion and fire occurred on December 19, 2007, in Jacksonville, Florida, resulting in the deaths of four people and the injury of fourteen others. T2 Laboratories Inc. was a facility that specialized in the design and manufacture of specialty chemicals primarily for gasoline additives.

Hydrogen safety covers the safe production, handling and use of hydrogen - particularly hydrogen gas fuel and liquid hydrogen. The main concern in working with hydrogen is flammability.

An explosion is a rapid expansion in volume associated with an extremely vigorous outward release of energy, usually with the generation of high temperatures and release of high-pressure gases. Supersonic explosions created by high explosives are known as detonations and travel through shock waves. Subsonic explosions are created by low explosives through a slower combustion process known as deflagration.

Nitrogen generators and stations are stationary or mobile air-to-nitrogen production complexes.

The Williams Olefins Plant explosion occurred on June 13, 2013 at a petrochemical plant located in Geismar, an unincorporated and largely industrial area 20 miles (32 km) southeast of Baton Rouge, Louisiana. Two workers were killed and 114 injured. The U.S. Occupational Safety and Health Administration (OSHA) and the U.S. Chemical Safety and Hazard Investigation Board (CSB) launched investigations to determine how and why the heat exchanger failed. The Chemical Safety Board concluded that a standby heat exchanger had filled with hydrocarbon. This heat exchanger was isolated from its pressure relief; shortly after the heat exchanger was heated with hot water, the hydrocarbon flashed to vapor, ruptured the heat exchanger, and exploded.

Many laboratories contain significant risks, and the prevention of laboratory accidents requires great care and constant vigilance. Examples of risk factors include high voltages, high and low pressures and temperatures, corrosive and toxic chemicals and chemical vapours, radiation, fire, explosions, and biohazards including infective organisms and their toxins.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

The health and safety hazards of nanomaterials include the potential toxicity of various types of nanomaterials, as well as fire and dust explosion hazards. Because nanotechnology is a recent development, the health and safety effects of exposures to nanomaterials, and what levels of exposure may be acceptable, are subjects of ongoing research. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure, and dust explosion hazards, are also a concern.