Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is being done to try to reduce the emissions or make concrete a source of carbon sequestration, and increase recycled and secondary raw materials content into the mix to achieve a circular economy. Concrete is expected to be a key material for structures resilient to climate disasters, as well as a solution to mitigate the pollution of other industries, capturing wastes such as coal fly ash or bauxite tailings and residue.

Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and muscles' that create the form and shape of man-made structures. Structural engineers also must understand and calculate the stability, strength, rigidity and earthquake-susceptibility of built structures for buildings and nonbuilding structures. The structural designs are integrated with those of other designers such as architects and building services engineer and often supervise the construction of projects by contractors on site. They can also be involved in the design of machinery, medical equipment, and vehicles where structural integrity affects functioning and safety. See glossary of structural engineering.

Reinforced concrete (RC), also called reinforced cement concrete (RCC) and ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

Tensegrity, tensional integrity or floating compression is a structural principle based on a system of isolated components under compression inside a network of continuous tension, and arranged in such a way that the compressed members do not touch each other while the prestressed tensioned members delineate the system spatially.

Eugène Freyssinet was a French structural and civil engineer. He was the major pioneer of prestressed concrete.

A beam is a structural element that primarily resists loads applied laterally to the beam's axis. Its mode of deflection is primarily by bending. The loads applied to the beam result in reaction forces at the beam's support points. The total effect of all the forces acting on the beam is to produce shear forces and bending moments within the beams, that in turn induce internal stresses, strains and deflections of the beam. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and their material.

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service.

Earthquake engineering is an interdisciplinary branch of engineering that designs and analyzes structures, such as buildings and bridges, with earthquakes in mind. Its overall goal is to make such structures more resistant to earthquakes. An earthquake engineer aims to construct structures that will not be damaged in minor shaking and will avoid serious damage or collapse in a major earthquake. Earthquake engineering is the scientific field concerned with protecting society, the natural environment, and the man-made environment from earthquakes by limiting the seismic risk to socio-economically acceptable levels. Traditionally, it has been narrowly defined as the study of the behavior of structures and geo-structures subject to seismic loading; it is considered as a subset of structural engineering, geotechnical engineering, mechanical engineering, chemical engineering, applied physics, etc. However, the tremendous costs experienced in recent earthquakes have led to an expansion of its scope to encompass disciplines from the wider field of civil engineering, mechanical engineering, nuclear engineering, and from the social sciences, especially sociology, political science, economics, and finance.

An extradosed bridge employs a structure that combines the main elements of both a prestressed box girder bridge and a cable-stayed bridge. The name comes from the word extrados, the exterior or upper curve of an arch, and refers to how the "stay cables" on an extradosed bridge are not considered as such in the design, but are instead treated as external prestressing tendons deviating upward from the deck. In this concept, they remain part of the main bridge superstructure.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

Offshore concrete structures have been in use successfully for about 50 years. They serve the same purpose as their steel counterparts in the oil and gas production and storage. The first concrete oil platform has been installed in the North Sea in the Ekofisk field in 1973 by Phillips Petroleum. Since then 47 major concrete offshore structures have been built.

BS 5400 was a British Standard code of practice for the design and construction of steel, concrete and composite bridges. It was applicable to highway, railway and pedestrian bridges. It has now been replaced by the European standard, BS EN 1991-2_2003 and other Eurocodes for the design of steel and concrete structures.

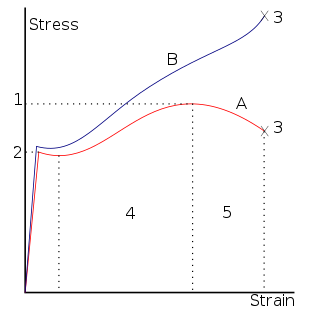

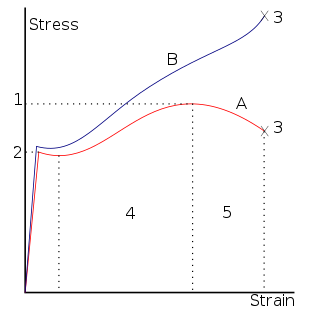

Structural engineering depends on the knowledge of materials and their properties, in order to understand how different materials resist and support loads.

In the Eurocode series of European standards (EN) related to construction, Eurocode 2: Design of concrete structures specifies technical rules for the design of concrete, reinforced concrete and prestressed concrete structures, using the limit state design philosophy. It was approved by the European Committee for Standardization (CEN) on 16 April 2004 to enable designers across Europe to practice in any country that adopts the code.

Concrete has relatively high compressive strength, but significantly lower tensile strength. The compressive strength is typically controlled with the ratio of water to cement when forming the concrete, and tensile strength is increased by additives, typically steel, to create reinforced concrete. In other words we can say concrete is made up of sand, ballast, cement and water.

The Olivetti-Underwood Factory was designed by architect Louis Kahn. Olivetti, an Italian company, commissioned Kahn in 1966 to design the Harrisburg, Pennsylvania building for the manufacture of their Underwood line of typewriters and related products. It was completed in 1970.

Kolbjørn Saether P.E., M.ASCE was an American structural engineer in the City of Chicago for 47 years. Saether dedicated his life to engineering and was known as a leader in his field. He was a past director of the Structural Engineers Association of Illinois and was the organization's president from 1980 to 1981. During his career he developed innovative engineering solutions for skyrise building construction that are now part of the Chicago skyline, published theoretical insights to enhance the state of the art in structural engineering, and patented novel techniques to advance the art of building construction.

This page is a glossary of Prestressed concrete terms.

PC Strand, or prestressed concrete steel strand, is a twisted steel cable composed of 2, 3, 7 or 19 high strength steel wires and is stress-relieved (stabilized) for prestressed concrete or similar purposes.

The Adam Viaduct is a grade II listed concrete underbridge in Wallgate, Wigan. The bridge, constructed in 1946, is the earliest prestressed concrete railway bridge in the United Kingdom, with only some examples in Switzerland being earlier. It is bridge number 54 on the Kirkby branch line and is at a line distance of 18 miles 1,032 yards (29.91 km).