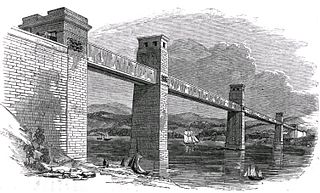

A Fairbairn crane is a type of crane of an 'improved design', patented in 1850 by Sir William Fairbairn. There are numerous hand-powered versions around the world and one surviving steam-powered example in Bristol Docks, England.

A Fairbairn crane is a type of crane of an 'improved design', patented in 1850 by Sir William Fairbairn. There are numerous hand-powered versions around the world and one surviving steam-powered example in Bristol Docks, England.

The crane's innovation was in the use of a curved jib, made of riveted wrought iron platework to form a square-section box girder. This curved jib could reach further into the hold of a ship, clear of the deep gunwales alongside the quay. [1]

Designing a strong curved jib required Fairbairn's advanced theoretical understanding of the mechanics of a box girder. The tension forces were carried by the outer, convex surface of the girder which was made of back plates being chain-riveted together. The inner surface carried a compressive load. To avoid plate crumpling, it was made as a cellular structure: an inner plate and webs formed three rectangular cells, effectively box girders in their own right. The character of a box girder is to resist torsional twisting, so a composite face built up of them is also good at resisting crumpling. [1]

The first of these cranes were a batch of six built for the Admiralty at Keyham and Devonport. These were hand-operated and could lift 12 tons to a height of 30 feet (9.1 m) and a radius of 32 feet (9.8 m) . [1] The size of the crane jibs was determined by ships of the period, and their lifting capacity by men's ability to raise the load. Experiments at Keyham with loads of up to 20 tons showed the jib design to be sound, and that the jib at least was capable of handling loads of up to 60 tons. [1]

A "colossal" crane of 60 tons was later built at Keyham, with a cell plate stiffened by four cells. [1] This crane was worked by four men driving through a gear train of 632 times, which must have been hard and slow work at full capacity. As the capacity of the crane was so obviously limited by its motive power, not its strength, they were an obvious candidate for steam power – as was later re-applied to the 60 ton crane at Keysham. There was even a proposal for a 120 feet (36.6 m) high crane, to replace masting sheers at Woolwich. A more typical size for most of these later cranes though would be able to lift 35 tons at a radius of 35 feet (10.7 m). They were powered by self-contained steam engines, with both boiler and engine mounted on board the crane.

William Fairbairn & Sons of Manchester built a number of these cranes and also licensed the design to other makers. After the expiry of the patent in 1875, other companies, notably Cowans Sheldon & Co of Carlisle, built many others as late as 1910, often powered by steam, water hydraulics or electricity. [2] They were particularly favoured in naval dockyards for fitting battleship guns; Hong Kong had a battery of four.

The only surviving Fairbairn steam crane is in Bristol, on the quayside at Wapping Wharf in the Floating Harbour. It is in the care of the M Shed museum, located on the adjacent Prince's Wharf. [3] [4]

In the 1870s, Bristol Docks was going through a period of expansion and modernisation in the face of increasing competition from other ports. Iron-hulled ships were becoming larger, cargoes heavier, and there had already been investment in building a railway line along the harbour quay. Crane capacity was limited, though – none of the harbour's 17 cranes being able to lift more than 3 tons.

Accordingly, a more powerful steam crane was ordered, to be capable of lifting 35 tons and loading it directly onto a railway wagon. This was ordered from local makers Stothert & Pitt in 1875, although to the Fairbairn pattern. As for the later Fairbairn cranes, the original cell plate was changed to a design of a single flat plate stiffened by riveted T section ribs, rather than the original cellular structure. [1] In August 1878 the crane had been completed and tested, at a cost of £3,600 for the machinery, plus the masonry foundations.

The jib has a radius (reach) of 35 feet (11 m) and a height of 40 feet (12 m). The crane weighs 120 tons. A vertical boiler inside the cab operates at 100 psi and supplies two twin-cylinder steam engines: one for slewing (turning) the crane, a larger one for winding the lifting chain. The winding drums can be driven by their gearing at four different speeds. The jib box girder extends below ground in a well for 25 feet (7.6 m). A plain bearing at the foot of the well carries the weight of the crane and roller bearings beneath the cab resist tipping loads. Water for the boiler is supplied by a pump, which originally drew water straight from the dock and is also used for draining the well. The boiler's maker's plate reads "Marshall Sons & Co. Ltd., Engineers, Gainsboro, England, No.92766"; it is the fourth boiler that has served the crane and was installed in 1953.

The cab of the crane is also of iron, with small-paned windows. These window frames are decorated with small roses cast into the junctions of the glazing bars. Some time around 1900 the top winding drums and gears were enclosed in a further box on the roof. [5]

Although mechanically capable, the crane was not a great success commercially. In 1890 it was only used for 16 days of the year, for a profit of just 11s. 6d. [5] Ships had increased in size by this time and the jib could no longer reach far enough to remove engines or boilers for repair work. It was even considered raising the crane up on a stone tower, as for the smaller crane at Canons Marsh opposite, to increase the lift height.

In 1892, hydraulic machinery, including cranes, appeared in the docks. These used a powerful central power supply and could transfer cargoes more quickly. In 1906 electric cranes appeared too. The steam crane was required less and less often; for a whole year between April 1905 and April 1906 the crane went unused. [5] From 1903 to 1909 it made a total of 143 lifts. [5] It remained useful for heavy loads, however.

During World War II the crane's heavy capacity came into its own. A Landing Craft Flotilla Unit was stationed on Princes Wharf, and over 1000 new assault landing craft were delivered by road for adaptation for use in the Far East. The crane was used to unload the lorries and to launch the craft after completion, a total of over 2000 lifts in three years.

The crane is still operational and is regularly steamed.

With the gradual closure of the City Docks, in 1973 the crane was passed to Bristol City Museum. In 1972 it was grade II* listed [4] and it is also a scheduled monument, [6] as the last surviving Fairbairn steam crane. From 1988, it was restored to operational condition as part of the Bristol Industrial Museum. The crane operates on special museum days, such as bank holidays and the Harbour Festival.

A hand-cranked example survives in Seville, Spain.

Another Fairbairn crane survives at Dover, on the quayside of Wellington Dock. [7] It is now a scheduled monument. [8] This is a hand-cranked crane of 1868, built by the Fairbairn Engineering Company of Manchester. [9] When originally installed it was rated at 50 tons and worked by four men. The Ordnance Department of the Royal Navy used it for handling cannon. In later years it was down-rated to 20 tons and was used for lifting yachts from what was now Dover Marina. In 2014 the crane was 'lovingly restored' [10] and repainted, with an obtrusive vertical steel prop beneath the jib. [11]

A crane is a machine used to move materials both vertically and horizontally, utilizing a system of a boom, hoist, wire ropes or chains, and sheaves for lifting and relocating heavy objects within the swing of its boom. The device uses one or more simple machines, such as the lever and pulley, to create mechanical advantage to do its work. Cranes are commonly employed in transportation for the loading and unloading of freight, in construction for the movement of materials, and in manufacturing for the assembling of heavy equipment.

The Bristol Industrial Museum was a museum in Bristol, England, located on Prince's Wharf beside the Floating Harbour and which closed in 2006. On display were items from Bristol's industrial past – including aviation, car and bus manufacture, and printing – and exhibits documenting Bristol's maritime history. The museum was managed by Bristol City Council along with nearby preserved industrial relics along Prince's Wharf, including the Bristol Harbour Railway, cranes and a small fleet of preserved vessels. The railway, cranes and vessels all now form part of the working exhibits at M Shed Museum.

A container crane is a type of large dockside gantry crane found at container terminals for loading and unloading intermodal containers from container ships.

The Finnieston Crane or Stobcross Crane is a disused giant cantilever crane in the centre of Glasgow, Scotland. It is no longer operational, but is retained as a symbol of the city's engineering heritage. The crane was used for loading cargo, in particular steam locomotives, onto ships to be exported around the world.

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of two parallel rails seated on longitudinal I-beams attached to opposite steel columns by means of brackets. The traveling bridge spans the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on two fixed rails at ground level, the crane is called a gantry crane or a goliath crane.

A box girder or tubular girder is a girder that forms an enclosed tube with multiple walls, as opposed to an Ɪ- or H-beam. Originally constructed of wrought iron joined by riveting, they are now made of rolled or welded steel, aluminium extrusions or prestressed concrete.

A steam crane is a crane powered by a steam engine. It may be fixed or mobile and, if mobile, it may run on rail tracks, caterpillar tracks, road wheels, or be mounted on a barge. It usually has a vertical boiler placed at the back so that the weight of the boiler counterbalances the weight of the jib and load.

Titan Clydebank, more commonly known as the Titan Crane is a 150-foot-high (46 m) cantilever crane at Clydebank, West Dunbartonshire, Scotland. It was designed to be used in the lifting of heavy equipment, such as engines and boilers, during the fitting-out of battleships and ocean liners at the John Brown & Company shipyard. It was also the world's first electrically powered cantilever crane, and the largest crane of its type at the time of its completion.

The Underfall Yard is a historic boatyard on Spike Island serving Bristol Harbour in England.

Stothert & Pitt was a British engineering company founded in 1855 in Bath, England. It was the builder of various engineering products ranging from Dock cranes to construction plant and household cast iron items. It went out of business in 1989. The name and intellectual property became part of Clarke Chapman.

Titan was a floating crane that operated in Sydney Harbour from 1919 until 1991. She was fabricated in Carlisle in the United Kingdom and then sent to Cockatoo Island Dockyard in Sydney for assembly before entering service with the Royal Australian Navy (RAN).

Mastekranen is an 18th-century masting sheer and present landmark on Holmen in Copenhagen, Denmark. It was designed by architect Philip de Lange and built in 1748–51 as part of the Royal Naval Shipyard at Holmen.

M Shed is a museum in Bristol, England, located on Prince's Wharf beside the Floating Harbour in a dockside transit shed formerly occupied by Bristol Industrial Museum. The museum's name is derived from the way that the port identified each of its sheds. M Shed is home to displays of 3,000 artefacts and stories, showing Bristol's role in the slave trade and items on transport, people, and the arts. Admission is free.

Mayflower is a steam tug built in Bristol in 1861 and now preserved by Bristol Museums Galleries & Archives. She is based in Bristol Harbour at M Shed. She is the oldest Bristol-built ship afloat, and is believed to be the oldest surviving tug in the world.

The Port of Bridgwater is a port, originally located in the town of Bridgwater, Somerset, England. Created under the Bridgwater Navigation and Quays Act 1845 it extends from Brean Down to Hinkley Point in Bridgwater Bay, and parts of the rivers Parrett, River Brue and River Axe. Although no ships now dock in the town, in 2001 103,613 (metric) tonnes of cargo were handled within the area of the Port Authority, most of which were stone products through the wharf at Dunball.

A balloon flange girder is a form of vertical I-beam wrought iron plate girder, where the top flange, instead of being a simple flat plate, is extended into a hollow tube. When a girder is subjected to a positive bending moment the top flange acts in compression making a flat plate flange more susceptible to local buckling than the balloon flange is.

Bertha is a steam-powered boat built in 1844 to remove silt from the Port of Bridgwater in Somerset, England. It is the oldest operational steam vessel in Britain, and possibly in the world. It is part of the National Historic Fleet.

A block-setting crane is a form of crane. They were used for installing the large stone blocks used to build breakwaters, moles and stone piers.

A Hercules crane was a form of block-setting crane, developed in the 1870s. They were characterised by a wheeled, mobile gantry running on rails, surmounted by a slewing horizontal jib, held up by a kingpost.

The Arrol Gantry was a large steel structure built by Sir William Arrol & Co. at the Harland and Wolff shipyard in Belfast, Northern Ireland. It was built to act as overhead cranes for the building of the three Olympic-class liners.

fairbairn boiler.