A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

Ralph Edward Flanders was an American mechanical engineer, industrialist and politician who served as a Republican U.S. Senator from the state of Vermont. He grew up on subsistence farms in Vermont and Rhode Island and was an apprentice machinist and draftsman before training as a mechanical engineer. He spent five years in New York City as an editor for a machine tool magazine. After moving back to Vermont, he managed and then became president of a successful machine tool company. Flanders used his experience as an industrialist to advise state and national commissions in Vermont, New England and Washington, D.C., on industrial and economic policy. He was president of the Boston Federal Reserve Bank for two years before being elected U.S. Senator from Vermont.

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as "the mysteries of the turners' guild." The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe.

A mandrel, mandril, or arbor is a tapered tool against which material can be forged, pressed, stretched or shaped, or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an opposing thread is screwed onto the mandrel.

The phrase speeds and feeds or feeds and speeds refers to two separate parameters in machine tool practice, cutting speed and feed rate. They are often considered as a pair because of their combined effect on the cutting process. Each, however, can also be considered and analyzed in its own right.

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

A lathe dog is a mechanical device typically made of cast iron, steel or aluminum that transmits rotary motion from a faceplate to a workpiece mounted between centers in a lathe. The tail of the dog is rotated by a slot in a driving faceplate, a stud mounted on a faceplate, or sometimes a side of a chuck jaw. The workpiece passes through an aperture in the dog into which the work is secured by one or more setscrews or a clamp arrangement. The maximum cross sectional dimension of the workpiece is limited by the dimensions of the dog aperture. Lathe dogs are provided in straight tail or bent tail form, and may be single tail or double tail. A lathe dog designed to hold square, rectangular or odd-shaped work and having a moveable portion secured typically by two cap screws is called a clamp dog. Bent tail dogs are able to engage directly with a driving faceplate slot or a chuck jaw but can crowd work off centre if clearance is not present between the dog tail and a closed end of the faceplate slot. Straight tail dogs do not present the issue of crowding work off centre but require at least one driving stud to be mounted on the faceplate. If the rotating mass of the dog setup is not balanced, eccentric motion of the work may occur. Counterbalancing or reduced spindle speed may be required. Care must be taken by the operator when using lathe dogs, as it is easy to get snagged on one. Use of headless setscrews, preferably of multiple-spline drive design, that do not protrude above the outer surface of the dog is recommended. A lathe dog may also be used with some indexing heads and other tools with similar faceplates that turn about a center.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

In machining, boring is the process of enlarging a hole that has already been drilled by means of a single-point cutting tool, such as in boring a gun barrel or an engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

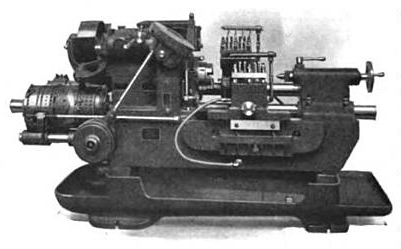

A turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the turret, which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes.

James Hartness was an American business executive, inventor, mechanical engineer, entrepreneur, amateur astronomer, and politician who served as the 58th governor of Vermont from 1921 to 1923.

Bryant is a brand of machine tools headquartered in Springfield, Vermont. Acquired by Fives in 2015, the Bryant product line specializes in the grinding field, building grinding machines with computer numerical control (CNC).

Shear forming, also referred as shear spinning, is similar to metal spinning. In shear spinning the area of the final piece is approximately equal to that of the flat sheet metal blank. The wall thickness is maintained by controlling the gap between the roller and the mandrel. In shear forming a reduction of the wall thickness occurs.

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers market Swiss-type CNC lathes as 'automatic'.

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe.

Joseph Wickham Roe was an American engineer and Professor of Industrial Engineering at the New York University, known for his seminal work on machine tools and machine tool builders history.

ASME B5 refers to a technical committee of the American Society of Mechanical Engineers and the standard they maintain which deals with machine tools.