Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate the free-stream flow of the fluid, and the interaction of the fluid with surfaces defined by boundary conditions. With high-speed supercomputers, better solutions can be achieved, and are often required to solve the largest and most complex problems. Ongoing research yields software that improves the accuracy and speed of complex simulation scenarios such as transonic or turbulent flows. Initial validation of such software is typically performed using experimental apparatus such as wind tunnels. In addition, previously performed analytical or empirical analysis of a particular problem can be used for comparison. A final validation is often performed using full-scale testing, such as flight tests.

The history of computing is longer than the history of computing hardware and modern computing technology and includes the history of methods intended for pen and paper or for chalk and slate, with or without the aid of tables.

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes finite element analysis (FEA), computational fluid dynamics (CFD), multibody dynamics (MBD), durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) in the collective abbreviation "CAx".

Introduced in June 1976, the TMS9900 was one of the first commercially available, single-chip 16-bit microprocessors. It implemented Texas Instruments' TI-990 minicomputer architecture in a single-chip format, and was initially used for low-end models of that lineup.

The NASA Advanced Supercomputing (NAS) Division is located at NASA Ames Research Center, Moffett Field in the heart of Silicon Valley in Mountain View, California. It has been the major supercomputing and modeling and simulation resource for NASA missions in aerodynamics, space exploration, studies in weather patterns and ocean currents, and space shuttle and aircraft design and development for almost forty years.

Elmer is computational tool for multi-physics problems. It has been developed by CSC in collaboration with Finnish universities, research laboratories and industry. Elmer FEM solver is free and open-source software, subject to the requirements of the GNU General Public License (GPL), version 2 or any later.

Computational electromagnetics (CEM), computational electrodynamics or electromagnetic modeling is the process of modeling the interaction of electromagnetic fields with physical objects and the environment.

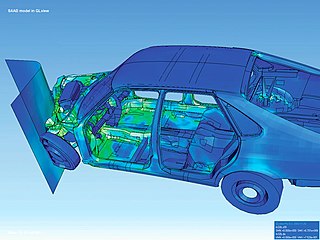

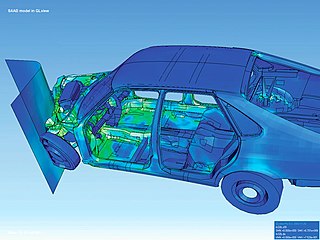

A crash simulation is a virtual recreation of a destructive crash test of a car or a highway guard rail system using a computer simulation in order to examine the level of safety of the car and its occupants. Crash simulations are used by automakers during computer-aided engineering (CAE) analysis for crashworthiness in the computer-aided design (CAD) process of modelling new cars. During a crash simulation, the kinetic energy, or energy of motion, that a vehicle has before the impact is transformed into deformation energy, mostly by plastic deformation (plasticity) of the car body material, at the end of the impact.

Dassault Systèmes Simulia Corp. is a computer-aided engineering (CAE) vendor. Formerly known as Abaqus Inc. and previously Hibbitt, Karlsson & Sorensen, Inc., (HKS), the company was founded in 1978 by David Hibbitt, Bengt Karlsson and Paul Sorensen, and has its headquarters in Providence, Rhode Island.

NEi Nastran was an engineering analysis and simulation software product of NEi Software Based on NASA's Structural Analysis program NASTRAN, the software is a finite element analysis (FEA) solver used to generate solutions for linear and nonlinear stress, dynamics, and heat transfer characteristics of structures and mechanical components. NEi Nastran software is used with all major industry pre and post processors including Femap, a product of Siemens PLM Software, in house brands NEi Nastran in-CAD, NEi Fusion, and NEi Works for SolidWorks. This software was acquired by Autodesk in May 2014.

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential.

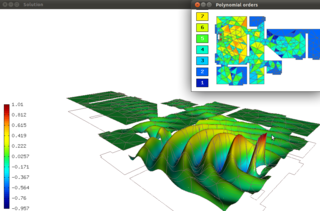

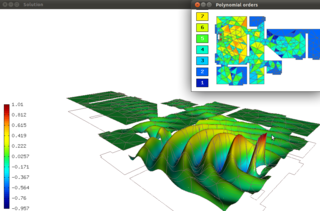

Hermes2D is a C++/Python library of algorithms for rapid development of adaptive hp-FEM solvers. hp-FEM is a modern version of the finite element method (FEM) that is capable of extremely fast, exponential convergence.

hp-FEM is a general version of the finite element method (FEM), a numerical method for solving partial differential equations based on piecewise-polynomial approximations that employs elements of variable size (h) and polynomial degree (p). The origins of hp-FEM date back to the pioneering work of Barna A. Szabó and Ivo Babuška who discovered that the finite element method converges exponentially fast when the mesh is refined using a suitable combination of h-refinements (dividing elements into smaller ones) and p-refinements. The exponential convergence makes the method a very attractive choice compared to most other finite element methods which only converge with an algebraic rate. The exponential convergence of the hp-FEM was not only predicted theoretically but also observed by numerous independent researchers.

OOFEM is a free and open-source multi-physics finite element code with object oriented architecture. The aim of this project is to provide efficient and robust tool for FEM computations as well as to offer highly modular and extensible environment for development.

VisualFEA is a finite element analysis software program for Microsoft Windows and Mac OS X. It is developed and distributed by Intuition Software, Inc. of South Korea, and used chiefly for structural and geotechnical analysis. Its strongest point is its intuitive, user-friendly design based on graphical pre- and postprocessing capabilities. It has educational features for teaching and learning structural mechanics, and finite element analysis through graphical simulation. It is widely used in college-level courses related to structural mechanics and finite element methods.

Olaf O. Storaasli, Synective Labs VP, was a researcher at Oak Ridge National Laboratory and USEC following his NASA career. He led the hardware, software and applications teams' successful development of one of NASA's 1st parallel computers, the Finite element machine and developed rapid matrix equation algorithms tailored to high-performance computers to solve science and engineering applications. He was PhD advisor and graduate instructor at UT, GWU and CNU and mentored 25 NHGS students. He is recognized by American Men and Women of Science, Marquis Who's Who, and NASA, Cray, Intel and Concordia College awards. NASA Awards include Viking Mars Lander design and Engineering Analysis.

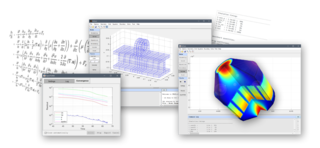

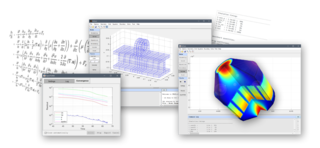

FEATool Multiphysics is a physics, finite element analysis (FEA), and PDE simulation toolbox. FEATool Multiphysics features the ability to model fully coupled heat transfer, fluid dynamics, chemical engineering, structural mechanics, fluid-structure interaction (FSI), electromagnetics, as well as user-defined and custom PDE problems in 1D, 2D (axisymmetry), or 3D, all within a graphical user interface (GUI) or optionally as script files. FEATool has been employed and used in academic research, teaching, and industrial engineering simulation contexts.

Guru Guruswamy is an American engineer working as Principal Scientist at Ames Research Center since 1988. He pioneered research in the area of computational aeroelasticity that involves Unsteady Aerodynamics, Finite Element Methods, Computational Fluid Dynamics, Parallel Computing and Problem Solving Environment. His innovative research was utilized in the first commercial 3-D computational aeroelasticity software developed by a major aerospace industry. The aeroelasticity legend Holt Ashley extensively referred to Guruswamy's research in his classical review paper. In 1988 he demonstrated the unique use of Transonic Small Perturbation based CFD for designing active controls to increase the safety of aircraft. It was followed by a break through development of Euler flow equations based Computational Aeroelasticy. It was cited by another Aeroelasticity legend John Dugundji of MIT as an important milestone in Aeroelasticity. A google search shows about 150 researchers took advantage Guruswamy's work based on the Euler equations for follow-up developments.