Related Research Articles

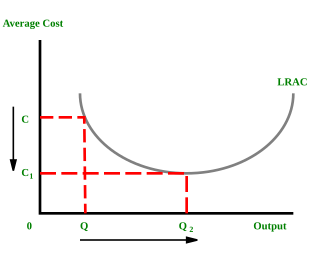

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of output produced per unit of time. A decrease in cost per unit of output enables an increase in scale that is, increased production with lowered cost. At the basis of economies of scale, there may be technical, statistical, organizational or related factors to the degree of market control.

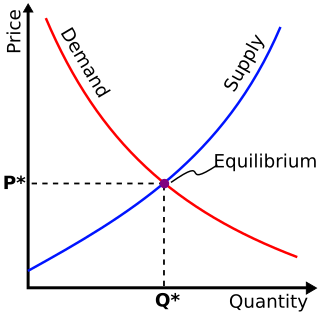

Microeconomics is a branch of economics that studies the behavior of individuals and firms in making decisions regarding the allocation of scarce resources and the interactions among these individuals and firms. Microeconomics focuses on the study of individual markets, sectors, or industries as opposed to the economy as a whole, which is studied in macroeconomics.

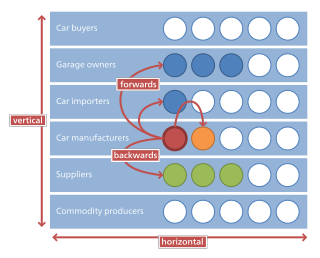

In microeconomics, management and international political economy, vertical integration, also referred to as vertical consolidation, is an arrangement in which the supply chain of a company is integrated and owned by that company. Usually each member of the supply chain produces a different product or (market-specific) service, and the products combine to satisfy a common need. It contrasts with horizontal integration, wherein a company produces several items that are related to one another. Vertical integration has also described management styles that bring large portions of the supply chain not only under a common ownership but also into one corporation.

Real options valuation, also often termed real options analysis, applies option valuation techniques to capital budgeting decisions. A real option itself, is the right—but not the obligation—to undertake certain business initiatives, such as deferring, abandoning, expanding, staging, or contracting a capital investment project. For example, real options valuation could examine the opportunity to invest in the expansion of a firm's factory and the alternative option to sell the factory.

Economies of scope are "efficiencies formed by variety, not volume". In the field of economics, "economies" is synonymous with cost savings and "scope" is synonymous with broadening production/services through diversified products. Economies of scope is an economic theory stating that average total cost of production decrease as a result of increasing the number of different goods produced. For example, a gas station that sells gasoline can sell soda, milk, baked goods, etc. through their customer service representatives and thus gasoline companies achieve economies of scope. The business historian Alfred Chandler argued that economies of scope contributed to the rise of American business corporations during the 20th century.

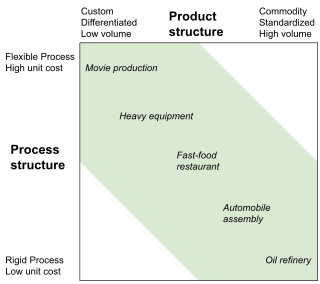

Mass customization makes use of flexible computer-aided systems to produce custom products. Such systems combine the low unit costs of mass production processes with the flexibility of individual customization.

Porter's Five Forces Framework is a method of analysing the competitive environment of a business. It draws from industrial organization (IO) economics to derive five forces that determine the competitive intensity and, therefore, the attractiveness of an industry in terms of its profitability. An "unattractive" industry is one in which the effect of these five forces reduces overall profitability. The most unattractive industry would be one approaching "pure competition", in which available profits for all firms are driven to normal profit levels. The five-forces perspective is associated with its originator, Michael E. Porter of Harvard University. This framework was first published in Harvard Business Review in 1979.

A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. It can range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems which are used for controlling processes or machines. The control systems are designed via control engineering process.

In microeconomics, diseconomies of scale are the cost disadvantages that economic actors accrue due to an increase in organizational size or in output, resulting in production of goods and services at increased per-unit costs. The concept of diseconomies of scale is the opposite of economies of scale. It occurs when economies of scale become dysfunctional for a firm. In business, diseconomies of scale are the features that lead to an increase in average costs as a business grows beyond a certain size.

An executive information system (EIS), also known as an executive support system (ESS), is a type of management support system that facilitates and supports senior executive information and decision-making needs. It provides easy access to internal and external information relevant to organizational goals. It is commonly considered a specialized form of decision support system (DSS).

A performance indicator or key performance indicator (KPI) is a type of performance measurement. KPIs evaluate the success of an organization or of a particular activity in which it engages. KPIs provide a focus for strategic and operational improvement, create an analytical basis for decision making and help focus attention on what matters most.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Quality, cost, delivery (QCD), sometimes expanded to quality, cost, delivery, morale, safety (QCDMS), is a management approach originally developed by the British automotive industry. QCD assess different components of the production process and provides feedback in the form of facts and figures that help managers make logical decisions. By using the gathered data, it is easier for organizations to prioritize their future goals. QCD helps break down processes to organize and prioritize efforts before they grow overwhelming.

Programming productivity describes the degree of the ability of individual programmers or development teams to build and evolve software systems. Productivity traditionally refers to the ratio between the quantity of software produced and the cost spent for it. Here the delicacy lies in finding a reasonable way to define software quantity.

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines, and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

In business, engineering, and manufacturing, quality – or high quality – has a pragmatic interpretation as the non-inferiority or superiority of something ; it is also defined as being suitable for the intended purpose while satisfying customer expectations. Quality is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Consumers may focus on the specification quality of a product/service, or how it compares to competitors in the marketplace. Producers might measure the conformance quality, or degree to which the product/service was produced correctly. Support personnel may measure quality in the degree that a product is reliable, maintainable, or sustainable. In such ways, the subjectivity of quality is rendered objective via operational definitions and measured with metrics such as proxy measures.

Production is the process of combining various inputs, both material and immaterial in order to create output. Ideally this output will be a good or service which has value and contributes to the utility of individuals. The area of economics that focuses on production is called production theory, and it is closely related to the consumption(or consumer) theory of economics.

Smart manufacturing is a broad category of manufacturing that employs computer-integrated manufacturing, high levels of adaptability and rapid design changes, digital information technology, and more flexible technical workforce training. Other goals sometimes include fast changes in production levels based on demand, optimization of the supply chain, efficient production and recyclability. In this concept, as smart factory has interoperable systems, multi-scale dynamic modelling and simulation, intelligent automation, strong cyber security, and networked sensors.

The Hayes-Wheelwright Matrix, also known as the product-process matrix, is a tool to analyze the fit between a chosen product positioning and manufacturing process.

References

- ↑ Srivastava, Samir K and Bansal, Sahil, "Measuring and Comparing Volume Flexibility across Indian Firms", International Journal of Business Performance Management, 14(1), 2013, pp. 38-51.