Related Research Articles

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

An automatic transmission is a multi-speed transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions. Vehicles with internal combustion engines, unlike electric vehicles, require the engine to operate in a narrow range of rates of rotation, requiring a gearbox, operated manually or automatically, to drive the wheels over a wide range of speeds.

A torque converter is a device, usually implemented as a type of fluid coupling, that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the torque converter connects the prime mover to the automatic gear train, which then drives the load. It is thus usually located between the engine's flexplate and the transmission. The equivalent device in a manual transmission is the mechanical clutch.

A transmission is a mechanical device which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

A manual transmission (MT), also known as manual gearbox, standard transmission, or stick shift, is a multi-speed motor vehicle transmission system where gear changes require the driver to manually select the gears by operating a gear stick and clutch.

A semi-automatic transmission is a multiple-speed transmission where part of its operation is automated, but the driver's input is still required to launch the vehicle from a standstill and to manually change gears. Semi-automatic transmissions were almost exclusively used in motorcycles and are based on conventional manual transmissions or sequential manual transmissions, but use an automatic clutch system. But some semi-automatic transmissions have also been based on standard hydraulic automatic transmissions with torque converters and planetary gearsets.

Hybrid Synergy Drive (HSD), also known as Toyota Hybrid System II, is the brand name of Toyota Motor Corporation for the hybrid car drive train technology used in vehicles with the Toyota and Lexus marques. First introduced on the Prius, the technology is an option on several other Toyota and Lexus vehicles and has been adapted for the electric drive system of the hydrogen-powered Mirai, and for a plug-in hybrid version of the Prius. Previously, Toyota also licensed its HSD technology to Nissan for use in its Nissan Altima Hybrid. Its parts supplier Aisin offers similar hybrid transmissions to other car companies.

Hydramatic is an automatic transmission developed by both General Motors' Cadillac and Oldsmobile divisions. Introduced in 1939 for the 1940 model year vehicles, the Hydramatic was the first mass-produced fully-automatic transmission developed for passenger automobile use.

TorqueFlite is the trademarked name of Chrysler Corporation's automatic transmissions, starting with the three-speed unit introduced late in the 1956 model year as a successor to Chrysler's two-speed PowerFlite. In the 1990s, the TorqueFlite name was dropped in favor of alphanumeric designations, although the latest Chrysler eight-speed automatic transmission has revived the name.

A starter ring gear is a part attached to an internal combustion engine that is part of the assembly which transfers the torque from the starter motor to the engine's crankshaft, in order to start the engine. The starter ring gear is usually made from medium carbon steel.

Roto Hydramatic was an automatic transmission built by General Motors and used in some Oldsmobile, Pontiac and Holden models between 1961 and 1965. It was based on the earlier, four-speed Hydramatic, but was more compact, providing only three forward speeds plus a small 8" fluid coupling with a stator inside of the fluid coupling. Oldsmobile, one of the companies that used this transmission in some of its cars, called the fluid couplings stator the "Accel-A-Rotor." The lightweight, aluminum-cased transmission was sometimes nicknamed the "Slim Jim." HydraMatic Division calls the Roto a four-range, three-gear HydraMatic.

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

A friction drive or friction engine is a type of transmission that utilises the static friction of two smooth surfaces to transfer torque between two rotating parts.

Vehicles made by American Motors Corporation (AMC) and Jeep incorporated a variety of transmissions and transfer case systems. This article covers transmissions used in the following vehicle models and years:

The Turboglide is a Chevrolet constant torque, continuously variable automatic transmission first offered as an option on Chevrolet V8 passenger cars for 1957. It consisted of a turbine-driven planetary gearbox with a 'switch pitch' dual-pitch torque converter stator. It had a die-cast aluminum transmission case, like Packard's Ultramatic of 1956. Turboglide cost about $50 more than the Powerglide 2-speed automatic. It was available in all V8-powered 1957-1961 Chevrolet models except the Corvette. General Motors produced 646,000 of these transmissions during its production.

Chevrolet Corvair Powerglide is a two-speed automatic transmission designed specially for the then all-new 1960 Chevrolet Corvair compact car that emerged in the fall of 1959 as Chevrolet's competitor in the then booming small car market. The Corvair was powered by a rear-mounted Chevrolet Turbo-Air 6 engine that necessitated a specially designed transaxle. Corvair Powerglide took the principles of the standard Chevrolet Powerglide and modified them to suit the rear-mounted powertrain location of the new Corvair. The Corvair used the Powerglide for all 10 years it was produced; from 1961 to 1963, Pontiac used a modified version of Corvair Powerglide it called 'TempesTorque' for its front-engine, rear-transaxle Tempest, LeMans and Tempest LeMans cars.

A spline is a ridge or tooth on a drive shaft that matches with a groove in a mating piece and transfers torque to it, maintaining the angular correspondence between them.

9G-Tronic is Mercedes-Benz's trademark name for its 9-speed automatic transmission, starting off with the W9A 700 as core model. The transmission debuted on the E 350 BlueTEC in 2013, and successively replaced both the 7-speed 7G-Tronic (PLUS) transmission and the 5-speed 5G-Tronic transmission. It includes versions for a maximum input torque of 1,000 N⋅m (738 lb⋅ft).

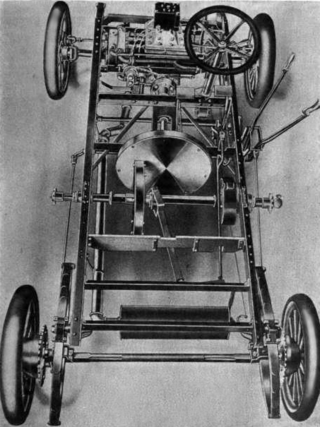

A drivetrain or transmission system, is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components.

References

- ↑ Zhang, Da Ke; Wang, Chong; Yang, Yi Chao; He, Han (January 2013). "The Layout Optimization for Axial Stiffness of a Flexplate Disk with Weight and Inertial Moment Constraints". ResearchGate.

- ↑ "Flex plate – What Does It Do?". Guard My Ride. 2022-09-26. Retrieved 2023-10-23.

- ↑ South African Automotive Light Vehicle Level 4. Jones & Bartlett Learning. 2013-06-15. ISBN 978-1-4496-9788-4 . Retrieved 2024-11-08– via Google Books.

- ↑ "How an Engine Flex Plate Works". 2carpros.com. 2022-03-11. Retrieved 2023-10-23.

- ↑ Patterson, Jeremy (2015-11-23). "Flexplate Technology And Choosing The Flexplate For You". Dragzine. Retrieved 2023-10-23.