Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals. A consistent particle size distribution is a reason for spray drying some industrial products such as catalysts. Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen-sensitive then nitrogen is used.

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

A clothes dryer, also known as tumble dryer, is a powered household appliance that is used to remove moisture from a load of clothing, bedding and other textiles, usually shortly after they are washed in a washing machine. Otherwise, clothes may also be dried by natural evaporation and, if available, sunlight, on an outdoor or indoor clothes line or clothes horse.

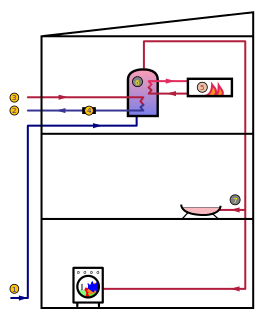

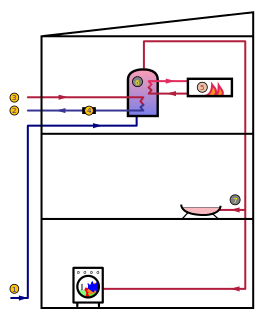

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR), is an energy recovery ventilation system which works between two sources at different temperatures. Heat recovery is a method which is increasingly used to reduce the heating and cooling demands of buildings. By recovering the residual heat in the exhaust gas, the fresh air introduced into the air conditioning system is pre-heated (pre-cooled), and the fresh air enthalpy is increased (reduced) before the fresh air enters the room or the air cooler of the air conditioning unit performs heat and moisture treatment. A typical heat recovery system in buildings consists of a core unit, channels for fresh air and exhaust air, and blower fans. Building exhaust air is used as either a heat source or heat sink depending on the climate conditions, time of year and requirements of the building. Heat recovery systems typically recover about 60–95% of the heat in exhaust air and have significantly improved the energy efficiency of buildings.

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improves the energy efficiency of the system as a whole.

Scrubber systems are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. The first air scrubber was designed to remove carbon dioxide from the air of an early submarine, the Ictineo I, a role for which they continue to be used today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation. They are also used for the high flows in solar, PV, or LED processes.

The rotary dryer is a type of industrial dryer used to reduce or minimize the moisture content of the material it is handling by bringing it into contact with a heated gas. The dryer is made up of a rotating cylinder, a drive mechanism, and a support structure. The cylinder is inclined slightly with the discharge end is lower than the material feed end so that material moves through the dryer under the influence of gravity. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of fins lining the inner wall of the dryer. When the material gets high enough, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

Energy recovery ventilation (ERV) is the energy recovery process in residential and commercial HVAC systems that exchanges the energy contained in normally exhausted air of a building or conditioned space, using it to treat (precondition) the incoming outdoor ventilation air. The specific equipment involved may be called an Energy Recovery Ventilator, also abbreviated ERV.

Low-temperature thermal desorption (LTTD), also known as low-temperature thermal volatilization, thermal stripping, and soil roasting, is an ex-situ remedial technology that uses heat to physically separate petroleum hydrocarbons from excavated soils. Thermal desorbers are designed to heat soils to temperatures sufficient to cause constituents to volatilize and desorb from the soil. Although they are not designed to decompose organic constituents, thermal desorbers can, depending upon the specific organics present and the temperature of the desorber system, cause some organic constituents to completely or partially decompose. The vaporized hydrocarbons are generally treated in a secondary treatment unit prior to discharge to the atmosphere. Afterburners and oxidizers destroy the organic constituents. Condensers and carbon adsorption units trap organic compounds for subsequent treatment or disposal.

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. To accomplish this the hot fluid is brought into contact with the heat storage medium, then the fluid is displaced with the cold fluid, which absorbs the heat.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

A sectional cooler is a type of liquid cooled rotary drum cooler used for continuous processes in chemical engineering. Sectional coolers consist of a rotating cylinder, a drive unit and a support structure. At each end of the drum there are stationary chutes for material feed and outlet. Depending on the size of the cooler the drum is pivoted on a shaft running through its axis, or is supported on running treads or external ring gears. The interior of the drum consists of several wedge-shaped chambers arranged around a central hollow shaft. This arrangement is completely surrounded by a jacket of water. In the wedge-shaped chambers are angled fins or shovels which move material through the cooler as the drum is rotated.

Moving Bed Heat Exchangers are widely used in industry, on applications involving heat recovery and filtering.

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of an air-handling system or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

A run-around coil is a type of energy recovery heat exchanger most often positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, to recover the heat energy. Generally, it refers to any intermediate stream used to transfer heat between two streams that are not directly connected for reasons of safety or practicality. It may also be referred to as a run-around loop, a pump-around coil or a liquid coupled heat exchanger.

A rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage and a rotating part to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants. A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union,rotorseal,rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union

Vibratory Fluidized Bed (VFB) is a type of fluidized bed where the mechanical vibration enhances the performance of fluidization process. Since the first discovery of vibratory fluidized bed, its vibration properties proves to be more efficient in dealing with fine particles which appears to be very difficult to achieve with normal fluidized bed. Even though numerous publications and its popularity in industrial applications, the knowledge about vibratory dynamics and properties are very limited. Future research and development are needed to further improve this technology to bring it to another level.

Gyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine. Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products. This method is applicable for both wet and dry screening.

Compressed air dryers are special types of filter systems that are specifically designed to remove the water that is inherent in compressed air. The process of compressing air raises its temperature and concentrates atmospheric contaminants, primarily water vapor. Consequently, the compressed air is generally at an elevated temperature and 100% relative humidity. As the compressed air cools, water vapor condenses into the tank(s), pipes, hoses and tools that are downstream from the compressor. Water vapor is removed from compressed air to prevent condensation from occurring and to prevent moisture from interfering in sensitive industrial processes.