A lubricant is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

Spray drying is a method of forming a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals, or materials which may require extremely consistent, fine particle size. Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen-sensitive then nitrogen is used.

In industrial process engineering, mixing is a unit operation that involves manipulation of a heterogeneous physical system with the intent to make it more homogeneous. Familiar examples include pumping of the water in a swimming pool to homogenize the water temperature, and the stirring of pancake batter to eliminate lumps (deagglomeration).

Conching is a process used in the manufacture of chocolate whereby a surface scraping mixer and agitator, known as a conche, evenly distributes cocoa butter within chocolate and may act as a "polisher" of the particles. It also promotes flavor development through frictional heat, release of volatiles and acids, and oxidation. The name arises from the shape of the vessels initially used which resembled conch shells.

Electrophoretic deposition (EPD), is a term for a broad range of industrial processes which includes electrocoating, cathodic electrodeposition, anodic electrodeposition, and electrophoretic coating, or electrophoretic painting. A characteristic feature of this process is that colloidal particles suspended in a liquid medium migrate under the influence of an electric field (electrophoresis) and are deposited onto an electrode. All colloidal particles that can be used to form stable suspensions and that can carry a charge can be used in electrophoretic deposition. This includes materials such as polymers, pigments, dyes, ceramics and metals.

A thickening agent or thickener is a substance which can increase the viscosity of a liquid without substantially changing its other properties. Edible thickeners are commonly used to thicken sauces, soups, and puddings without altering their taste; thickeners are also used in paints, inks, explosives, and cosmetics.

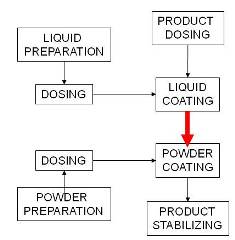

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a thick, tough finish that is more durable than conventional paint. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated, as little heat or oven dwell time is required to process them.

Dip coating is an industrial coating process which is used, for example, to manufacture bulk products such as coated fabrics and condoms and specialised coatings for example in the biomedical field. Dip coating is also commonly used in academic research, where many chemical and nano material engineering research projects use the dip coating technique to create thin-film coatings.

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied at 25–250 μm to the electronic circuitry and provide protection against moisture and other harsher conditions.

A spray nozzle or atomizer is a device that facilitates the dispersion of a liquid by the formation of a spray. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using kinetic energy to overcome the cost of creating additional surface area. A wide variety of spray nozzles exist, that make use of one or multiple liquid breakup mechanisms, which can be divided into three categories: liquid sheet breakup, jets and capillary waves. Spray nozzles are of great importance for many applications, where the spray nozzle is designed to have the right spray characteristics.

A high-shear mixer disperses, or transports, one phase or ingredient into a main continuous phase (liquid), with which it would normally be immiscible. A rotor or impeller, together with a stationary component known as a stator, or an array of rotors and stators, is used either in a tank containing the solution to be mixed, or in a pipe through which the solution passes, to create shear. A high-shear mixer can be used to create emulsions, suspensions, lyosols, and granular products. It is used in the adhesives, chemical, cosmetic, food, pharmaceutical, and plastics industries for emulsification, homogenization, particle size reduction, and dispersion.

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

Ultrasonic nozzles are a type of spray nozzle that use high frequency vibrations produced by piezoelectric transducers acting upon the nozzle tip that create capillary waves in a liquid film. Once the amplitude of the capillary waves reaches a critical height, they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization.

Curtain coating is a process that creates an uninterrupted curtain of fluid that falls onto a substrate. The substrate is transported on a conveyor belt or calender rolls at a regulated speed through the curtain to ensure an even coat of the die. The curtain is created by using a slit or die at the base of the holding tank, allowing the liquid to fall upon the substrate. Some polymers are melted and extruded for coating. Many manufactures will also include a catch pan to retrieve and reuse the excess fluid.

Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material. It is applied in several technological processes in the chemical and pharmaceutical industries. Typically, granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 4.0 mm depending on their subsequent use. Less commonly, it involves shredding or grinding solid material into finer granules or pellets.

Coated urea fertilizers are a group of controlled release fertilizers consisting of prills of urea coated in less-soluble chemicals such as sulfur, polymers, other products or a combination. These fertilizers mitigate some of the negative aspects of urea fertilization, such as fertilizer burn. The coatings release the urea either when penetrated by water, as with sulfur, or when broken down, as with polymers.

Industrial porcelain enamel is the use of porcelain enamel for industrial, rather than artistic, applications. Porcelain enamel, a thin layer of ceramic or glass applied to a substrate of metal, is used to protect surfaces from chemical attack and physical damage, modify the structural characteristics of the substrate, and improve the appearance of the product.

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically for smaller units and hydraulically for larger units to enable separation.

A die in polymer processing is a metal restrictor or channel capable of providing a constant cross sectional profile to a stream of liquid polymer. This allows for continuous processing of shapes such as sheets, films, pipes, rods, and other more complex profiles. This is a continuous process, allowing for constant production, as opposed to a sequential (non-constant) process such as injection molding.

Agglomerated food powder is a unit operation during which native particles are assembled to form bigger agglomerates, in which the original particle can still be distinguished. Agglomeration can be achieved through processes that use liquid as a binder or methods that do not involve any binder.