Computer-aided design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

A point cloud is a discrete set of data points in space. The points may represent a 3D shape or object. Each point position has its set of Cartesian coordinates. Points may contain data other than position such as RGB colors, normals, timestamps and others. Point clouds are generally produced by 3D scanners or by photogrammetry software, which measure many points on the external surfaces of objects around them. As the output of 3D scanning processes, point clouds are used for many purposes, including to create 3D computer-aided design (CAD) or geographic information systems (GIS) models for manufactured parts, for metrology and quality inspection, and for a multitude of visualizing, animating, rendering, and mass customization applications.

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

Solid modeling is a consistent set of principles for mathematical and computer modeling of three-dimensional shapes (solids). Solid modeling is distinguished within the broader related areas of geometric modeling and computer graphics, such as 3D modeling, by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D-computer-aided design, and in general, support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects.

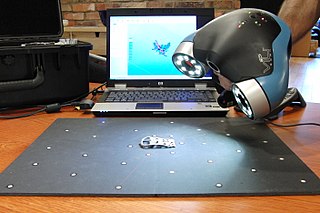

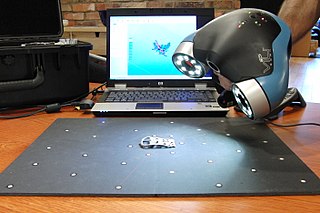

A coordinate-measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, the most common being mechanical and laser sensors, though optical and white light sensors do exist. Depending on the machine, the probe position may be manually controlled by an operator, or it may be computer controlled. CMMs(coordinate-measuring machine) specify a probe's position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system. In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

3D scanning is the process of analyzing a real-world object or environment to collect three dimensional data of its shape and possibly its appearance. The collected data can then be used to construct digital 3D models.

DSSP stands for digital shape sampling and processing. It is an alternative and often preferred way of describing "reverse engineering" software and hardware. The term originated in a 2005 Society of Manufacturing Engineers' "Blue Book" on the topic, which referenced numerous suppliers of both scanning hardware and processing software.

CAD/CAM dentistry is a field of dentistry and prosthodontics using CAD/CAM to improve the design and creation of dental restorations, especially dental prostheses, including crowns, crown lays, veneers, inlays and onlays, fixed dental prostheses (bridges), dental implant supported restorations, dentures, and orthodontic appliances. CAD/CAM technology allows the delivery of a well-fitting, aesthetic, and a durable prostheses for the patient. CAD/CAM complements earlier technologies used for these purposes by any combination of increasing the speed of design and creation; increasing the convenience or simplicity of the design, creation, and insertion processes; and making possible restorations and appliances that otherwise would have been infeasible. Other goals include reducing unit cost and making affordable restorations and appliances that otherwise would have been prohibitively expensive. However, to date, chairside CAD/CAM often involves extra time on the part of the dentist, and the fee is often at least two times higher than for conventional restorative treatments using lab services.

Delcam is a supplier of advanced CAD/CAM software for the manufacturing industry. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University, UK. It is now a global developer of product design and manufacturing software, with subsidiaries and joint ventures in North America, South America, Europe and Asia with a total staff of over 800 people and local support provided from over 300 re-seller offices worldwide. It was listed on the London Stock Exchange until 6 February 2014, when it was acquired by Autodesk. It now operates as a wholly owned, independently operated subsidiary of Autodesk.

Vero Software is a company based in Cheltenham, England, that specialises in CAD CAM.

Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufacturing may also be referred to as machining, and many other technologies can be exploited to physically produce the designed objects.

BricsCAD® is a software application for computer-aided design (CAD), developed by Bricsys nv. The company was founded in 2002 by Erik de Keyser, a longtime CAD entrepreneur. In 2011 Bricsys acquired the intellectual property rights from Ledas for constraints-based parametric design tools, permitting the development of applications in the areas of direct modeling and assembly design. Bricsys is headquartered in Ghent, Belgium, and has additional development centers in Nizhny Novgorod and Novosibirsk, Russia; Bucharest, Romania and Singapore. Bricsys is a founding member of the Open Design Alliance, and joined the BuildingSMART International consortium in December 2016.

Computer-aided inspection (CAI) is the use of software tools to assess manufactured objects. It is closely related to computer-aided design (CAD) and computer-aided manufacturing (CAM). Its primary purpose is to allow engineers to more quickly and precisely assess the physical properties of manufactured objects. These properties can include dimensions, material consistency, roughness and roundness.

Image-based meshing is the automated process of creating computer models for computational fluid dynamics (CFD) and finite element analysis (FEA) from 3D image data. Although a wide range of mesh generation techniques are currently available, these were usually developed to generate models from computer-aided design (CAD), and therefore have difficulties meshing from 3D imaging data.

Synopsys Simpleware ScanIP is a 3D image processing and model generation software program developed by Synopsys Inc. to visualise, analyse, quantify, segment and export 3D image data from magnetic resonance imaging (MRI), computed tomography (CT), microtomography and other modalities for computer-aided design (CAD), finite element analysis (FEA), computational fluid dynamics (CFD), and 3D printing. The software is used in the life sciences, materials science, nondestructive testing, reverse engineering and petrophysics.

Industrial computed tomography (CT) scanning is any computer-aided tomographic process, usually X-ray computed tomography, that uses irradiation to produce three-dimensional internal and external representations of a scanned object. Industrial CT scanning has been used in many areas of industry for internal inspection of components. Some of the key uses for industrial CT scanning have been flaw detection, failure analysis, metrology, assembly analysis and reverse engineering applications. Just as in medical imaging, industrial imaging includes both nontomographic radiography and computed tomographic radiography.

In 3D computer graphics, 3D modeling is the process of developing a mathematical coordinate-based representation of a surface of an object in three dimensions via specialized software by manipulating edges, vertices, and polygons in a simulated 3D space.

Artec 3D is a developer and manufacturer of 3D scanning hardware and software. The company is headquartered in Luxembourg, with offices also in the United States, China (Shanghai), Japan (Tokyo), Portugal (Lisbon) and Montenegro (Bar). Artec 3D's products and services are used in various industries, including engineering, healthcare, media and design, entertainment, education, fashion and historic preservation. In 2013, Artec 3D launched an automated full-body 3D scanning system, Shapify.me, that creates 3D portraits called “Shapies.”