Related Research Articles

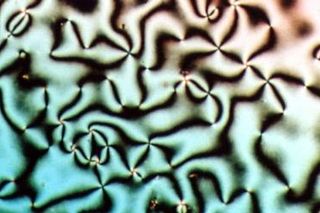

Liquid crystal (LC) is a state of matter whose properties are between those of conventional liquids and those of solid crystals. For example, a liquid crystal can flow like a liquid, but its molecules may be oriented in a common direction as in a solid. There are many types of LC phases, which can be distinguished by their optical properties. The contrasting textures arise due to molecules within one area of material ("domain") being oriented in the same direction but different areas having different orientations. An LC material may not always be in an LC state of matter.

Petrochemicals are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources such as maize, palm fruit or sugar cane.

Carbon fibers or carbon fibres are fibers about 5 to 10 micrometers (0.00020–0.00039 in) in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers.

Kerogen is solid, insoluble organic matter in sedimentary rocks. It consists of a variety of organic materials, including dead plants, algae, and other microorganisms, that have been compressed and heated by geological processes. All the kerogen on earth is estimated to contain 1016 tons of carbon. This makes it the most abundant source of organic compounds on earth, exceeding the total organic content of living matter 10,000-fold.

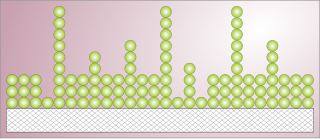

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. This process differs from absorption, in which a fluid is dissolved by or permeates a liquid or solid. While adsorption does often precede absorption, which involves the transfer of the absorbate into the volume of the absorbent material, alternatively, adsorption is distinctly a surface phenomenon, wherein the adsorbate does not penetrate through the material surface and into the bulk of the adsorbent. The term sorption encompasses both adsorption and absorption, and desorption is the reverse of sorption.

Thermal depolymerization (TDP) is the process of converting a polymer into a monomer or a mixture of monomers, by predominantly thermal means. It may be catalyzed or un-catalyzed and is distinct from other forms of depolymerization which may rely on the use of chemicals or biological action. This process is associated with an increase in entropy.

Pyrolysis is the process of thermal decomposition of materials at elevated temperatures, often in an inert atmosphere.

A polyamide is a polymer with repeating units linked by amide bonds.

Carbon is capable of forming many allotropes due to its valency. Well-known forms of carbon include diamond and graphite. In recent decades, many more allotropes have been discovered and researched, including ball shapes such as buckminsterfullerene and sheets such as graphene. Larger-scale structures of carbon include nanotubes, nanobuds and nanoribbons. Other unusual forms of carbon exist at very high temperatures or extreme pressures. Around 500 hypothetical 3‑periodic allotropes of carbon are known at the present time, according to the Samara Carbon Allotrope Database (SACADA).

Sulfur trioxide (alternative spelling sulphur trioxide, also known as nisso sulfan) is the chemical compound with the formula SO3. It has been described as "unquestionably the most [economically] important sulfur oxide". It is prepared on an industrial scale as a precursor to sulfuric acid.

Polyimide is a polymer containing imide groups belonging to the class of high-performance plastics. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, such as high temperature fuel cells, displays, and various military roles. A classic polyimide is Kapton, which is produced by condensation of pyromellitic dianhydride and 4,4'-oxydianiline.

Thermogravimetric analysis or thermal gravimetric analysis (TGA) is a method of thermal analysis in which the mass of a sample is measured over time as the temperature changes. This measurement provides information about physical phenomena, such as phase transitions, absorption, adsorption and desorption; as well as chemical phenomena including chemisorptions, thermal decomposition, and solid-gas reactions.

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves conversion of monomers in solution into a colloidal solution (sol) that acts as the precursor for an integrated network of either discrete particles or network polymers. Typical precursors are metal alkoxides. Sol–gel process is used to produce ceramic nanoparticles.

Liquid crystal polymers (LCPs) are polymers with the property of liquid crystal, usually containing aromatic rings as mesogens. Despite uncrosslinked LCPs, polymeric materials like liquid crystal elastomers (LCEs) and liquid crystal networks (LCNs) can exhibit liquid crystallinity as well. They are both crosslinked LCPs but have different cross link density. They are widely used in the digital display market. In addition, LCPs have unique properties like thermal actuation, anisotropic swelling, and soft elasticity. Therefore, they can be good actuators and sensors. One of the most famous and classical applications for LCPs is Kevlar, a strong but light fiber with wide applications, notably bulletproof vests.

Lyotropic liquid crystals result when amphiphiles, which are both hydrophobic and hydrophilic, dissolve into a solution that behaves both like a liquid and a solid crystal. This liquid crystalline mesophase includes everyday mixtures like soap and water.

Discotic liquid crystals are mesophases formed from disc-shaped molecules known as "discotic mesogens". These phases are often also referred to as columnar phases. Discotic mesogens are typically composed of an aromatic core surrounded by flexible alkyl chains. The aromatic cores allow charge transfer in the stacking direction through the π conjugate systems. The charge transfer allows the discotic liquid crystals to be electrically semiconductive along the stacking direction. Applications have been focusing on using these systems in photovoltaic devices, organic light emitting diodes (OLED), and molecular wires. Discotics have also been suggested for use in compensation films, for LCD displays.

C70 fullerene is the fullerene molecule consisting of 70 carbon atoms. It is a cage-like fused-ring structure which resembles a rugby ball, made of 25 hexagons and 12 pentagons, with a carbon atom at the vertices of each polygon and a bond along each polygon edge. A related fullerene molecule, named buckminsterfullerene (or C60 fullerene) consists of 60 carbon atoms.

Cyanogen fluoride is an inorganic linear compound which consists of a fluorine in a single bond with carbon, and a nitrogen in a triple bond with carbon. It is a toxic and explosive gas at room temperature. It is used in organic synthesis and can be produced by pyrolysis of cyanuric fluoride or by fluorination of cyanogen.

A carbon nanothread is a sp3-bonded, one-dimensional carbon crystalline nanomaterial. The tetrahedral sp3-bonding of its carbon is similar to that of diamond. Nanothreads are only a few atoms across, more than 300,000 times thinner than a human hair. They consist of a stiff, strong carbon core surrounded by hydrogen atoms. Carbon nanotubes, although also one-dimensional nanomaterials, in contrast have sp2-carbon bonding as is found in graphite. The smallest carbon nanothread has a diameter of only 0.2 nanometers, much smaller than the diameter of a single-wall carbon nanotube.

Carbon fiber is often time produced using two main methods: through the use of Polyacrylonitrile (PAN) and from pitch. Pitch is a viscoelastic material that is composed of aromatic hydrocarbons. Pitch is produced via the distillation of carbon-based materials, such as plants, crude oil, and coal. Pitch is isotropic, but can be made anisotropic through the use of heat treatments. However, the most important in carbon fiber production is mesophase pitch due to the ability to melt spin anisotropic mesophase pitch without filament breakage.

References

- ↑ R.E. Franklin (1951). "Crystallite growth in graphitizing and non-graphitizing carbons". Proceedings of the Royal Society A. 209 (1097): 196–218. Bibcode:1951RSPSA.209..196F. doi:10.1098/rspa.1951.0197. S2CID 4126286.

- ↑ H. Marsh and M.A. Diez (1994) " Mesophase of Graphitizable Carbons" In: Shibaev V.P., Lam L. (eds) Liquid Crystalline and Mesomorphic Polymers. Springer, New York, NY doi : 10.1007/978-1-4613-8333-8_7

- ↑ A. Oberlin (1984). "Carbonization and graphitization". Carbon. 22 (6): 521–541. doi:10.1016/0008-6223(84)90086-1.

- ↑ P.J.F. Harris (2013). "Fullerene-like models for microporous carbon" (PDF). Journal of Materials Science. 48 (2): 565–577. Bibcode:2013JMatS..48..565H. doi:10.1007/s10853-012-6788-1. S2CID 14903411.