This article addresses the history of papermaking in Massachusetts .

This article addresses the history of papermaking in Massachusetts .

Early paper in Massachusetts was, as was common in Europe, made from cotton and linen rags. [1] As the 18th century progressed, the demand for printed books was increasingly met by local printers, so the demand for paper increased and rags became scarce. [1] One paper manufacturer in Massachusetts even issued paper with a "Save Rags' watermark. [1] The shortage was so extreme during the American Revolution, that the Committees of Safety in Massachusetts were required to appoint a rag collector in each jurisdiction. [2]

In 1801, Zenas Crane began making paper in Dalton, Massachusetts, which later became Crane & Company. [3] In 1857 Crane & Company began making the paper for banknotes, [4] and it was confirmed as the paper of choice for U.S. currency beginning in 1862. As of 2012 [update] , Crane & Company continues to manufacture the paper for U.S. currency. [5] By 1840 Lee was the largest paper producer, and by Zenas Crane's death in 1845, Berkshire was the largest paper producing county in the United States. [6]

The "Turkey" mill in Tyringham was built by Milton Ingersol in 1833 to produce paper from rags. In 1835 it became the firm of Platner and Smith, which in 1850 purchased the Union and Enterprise mills on the Housatonic River in Lee, Massachusetts, and another mill on the Laurel Lake outlet. These three mills were called the Castle and Laurel paper mills. [7] Platner and Smith became the largest paper manufacture in the United States. [7] Subsequently, the firm was incorporated as the Smith Paper Company. [7]

In 1849, the Holyoke Dam was completed across the Connecticut River which started an expansion of mills, and especially paper mills throughout Massachusetts. The first of these mills, met with some resistance by the dam's investors at that time, was the Parsons Paper Company. In the subsequent decades the growth of the paper industry across Massachusetts was described as thus- [8]

For a time it seemed that paper mills sprung up like mushrooms, all up and down the streams in Lee, Tyringham, Stockbridge, Housatonic, Great Barrington, and there were times when men, seemingly bemused by the lure of this industry, erected little "one family" mills on their farms and went headlong into the business, knowing little or nothing about it and prospering little or none.

In 1857, the firm of Platner and Smith made paper from wood pulp, but their endeavor failed to be commercially viable because of the lengthy process used to reduce the wood to pulp and the high cost. The paper they produced was quite coarse and did not take print well. [9]

In 1866, Albrecht Pagenstecher, a German immigrant living in Stockbridge, Massachusetts, together with his brother Rudolf, bought two German-made Keller-Voelter grinders. On March 5, 1867, in nearby Curtisville, Pagenstecher was the first in the United States to manufacture commercially viable wood pulp. He sold the pulp to the Smith Paper Company which immediately produced commercial newsprint. [9] However, Pagenstecher initially made his pulp out of aspen or "popple"; however, he soon exhausted his supply of this tree and was forced to substitute with less friable softwoods, with the result that the New York World cancelled its contract for newsprint. [10]

Many of the Holyoke mills quickly converted to wood pulp, and Holyoke with twelve major paper mills became the world's largest center for papermaking. [11] Additionally the city was home to D. H. & A. B. Tower, who specialized in mills operating using the sulfite process; at one time their firm was reportedly the largest in the United States. [12] Because of its prominence in industrial papermaking, Holyoke's machinery and labor practices would be the subject of extensive study by officials and industrialists of Japan and China alike, who sought to modernize their production methods. [13] [14] [15] [16]

As local labor costs rose and wood became scarcer in Massachusetts, papermaking declined due in no small part to competition first from mills in well-forested Wisconsin and then from Canada. [11] Starting after World War I, paper mills in Massachusetts began to close. The industry survived by focusing on the manufacture of specialty papers, such as writing bond, which prospered until the 1970s.

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a specialized craft and a medium for artistic expression.

Pulp is a fibrous lignocellulosic material prepared by chemically, semi-chemically or mechanically producing cellulosic fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.

Lee is a town in Berkshire County, Massachusetts, United States. It is part of the Pittsfield, Massachusetts, metropolitan statistical area. The population was 5,788 at the 2020 census. Lee, which includes the villages of South and East Lee, is part of the Berkshires resort area.

The pulp and paper industry comprises companies that use wood, specifically pulpwood, as raw material and produce pulp, paper, paperboard, and other cellulose-based products.

The International Paper Company is an American pulp and paper company, the largest such company in the world. It has approximately 39,000 employees, and is headquartered in Memphis, Tennessee.

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags, and other ingredients. Prior to the invention and adoption of the Fourdrinier machine and other types of paper machine that use an endless belt, all paper in a paper mill was made by hand, one sheet at a time, by specialized laborers.

Charles Fenerty was a Canadian inventor who invented the wood pulp process for papermaking, which was first adapted into the production of newsprint. Fenerty was also a poet, writing over 32 known poems.

Arborite is the leading Canadian manufacturer of high-pressure decorative plastic laminates (HPL). Best known as a counter top surfacing material, this laminate is a durable decorative veneer applied to cabinetry, furniture, and other horizontal and vertical surfaces. The original Arborite material was developed in 1942 by the Howard Smith Paper Company as an innovative way to utilize waste by-products of the Canadian papermaking industry, and to this day any laminate used for the same purpose is commonly referred to in Canada by the trade name Arborite.

Printing and writing papers are paper grades used for newspapers, magazines, catalogs, books, notebooks, commercial printing, business forms, stationeries, copying and digital printing. About 1/3 of the total pulp and paper marked is printing and writing papers. The pulp or fibers used in printing and writing papers are extracted from wood using a chemical or mechanical process.

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses, herbivore dung, or other vegetable sources in water. Once the water is drained through a fine mesh leaving the fibre evenly distributed on the surface, it can be pressed and dried.

The Crane and Company Old Stone Mill Rag Room is one of the oldest surviving buildings of Crane & Co., one of the oldest papermaking businesses in Berkshire County, Massachusetts. It is located in southwestern Dalton, on a site where paper has been manufactured since the early 19th century. The building, originally used for processing rags, has housed the Crane Museum of Papermaking since 1930, and was designated a National Historic Landmark in 1983.

Mummy paper is paper that is claimed to be made from the linen wrappings and other fibers from Egyptian mummies imported to America circa 1855. The existence of this paper has not been conclusively confirmed, but it has been widely discussed.

Tree-free paper, also known as no tree paper, offers an alternative to traditional wood-pulp paper due to its unique raw material composition. This type of paper is considered more eco-friendly especially when evaluating its entire life cycle.

Paper is a thin nonwoven material traditionally made from a combination of milled plant and textile fibres. The first paper-like plant-based writing sheet was papyrus in Egypt, but the first true papermaking process was documented in China during the Eastern Han period, traditionally attributed to the court official Cai Lun. This plant-puree conglomerate produced by pulp mills and paper mills was used for writing, drawing, and money. During the 8th century, Chinese paper making spread to the Islamic world, replacing papyrus. By the 11th century, papermaking was brought to Europe, where it replaced animal-skin-based parchment and wood panels. By the 13th century, papermaking was refined with paper mills using waterwheels in Spain. Later improvements to the papermaking process came in 19th century Europe with the invention of wood-based papers.

The History of Papermaking in New York had its beginnings in the late 18th century, at a time when linen and cotton rags were the primary source of fibers in the manufacturing process. By 1850 there were more than 106 paper mills in New York, more than in any other state. A landmark in the history of papermaking in the United States was the installation of the first Fourdrinier machine in the country at a mill in Saugerties, New York, in 1827. Papermaking from ground-wood pulp began in New York in 1869, with the establishment of the Hudson River Pulp & Paper Company in Corinth and also with the work of Illustrious Remington and his sons in Watertown. The innovation and success of the Remingtons spurred further development of the industry in the state.

Doing business as D. H. & A. B. Tower, brothers David Horatio Tower and Ashley Bemis Tower were internationally known American architects, civil and mechanical engineers based in Holyoke, Massachusetts, who designed mills and factories in the United States from Maine to California as well as abroad, including in Canada, Mexico, Germany, Brazil, the United Kingdom, India, China, Japan, and Australia. By the time of its dissolution, the firm was described by one contemporary account as "the largest firm of paper mill architects in the country at that time"; its files reportedly contained more than 8,000 architectural plans for sites, mill machinery, and waterpower improvements.

The American Writing Paper Company was an American pulp and paper producing company trust, primarily manufacturing printing and writing paper. Incorporated in New Jersey in 1899 and representing the merging of 23 rag paper mills, the company held its general offices in Holyoke, Massachusetts which was also the location of 13 of these mills. At its peak output American Writing Paper produced 75% of all fine papers in the United States; contemporary accounts describe it as the largest producer of fine papers in the world.

The Holyoke Machine Company was an American manufacturer of industrial machinery, best known for its work in paper manufacturing equipment and water turbines.

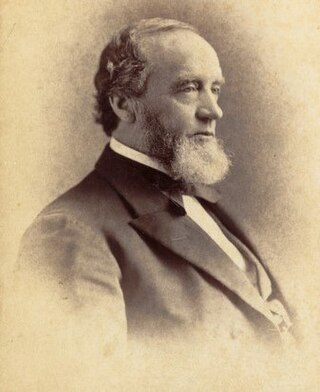

Elizur Smith was an American politician and paper manufacturer from Lee, Massachusetts. His enterprise, the Smith Paper Company, became the largest fine paper manufacturer in America. He also served in the Massachusetts House of Representatives and became a Senator from the southern Berkshire District in 1879. His breeding farm, named Highlawn, became one of the largest equestrian estate in the East Coast, and was later acquired by the Vanderbilts.

In 1879 Mr. Ellsworth left the firm of Davis & Ellsworth to become principal assistant and head draftsman for D. H. & A. B. Tower, of Holyoke, who were the largest firm of paper mill architects in the country at that time, and who designed no less than twenty paper mills in the city of Holyoke alone

Mr. Fugino [Fujino], who spent some months in the district of Holyoke, stated that the machines supplied to the mill were of American construction

Michiaki Kurokawa, vice-superintendent of the Fuji Paper Company, Tokio, Japan, has recently visited some of the paper mills in Western Massachusetts in company of Mr. Miller of the Cheney Bigelow Wire Works, whose new factory he had also the pleasure of inspecting. Mr. Kurokawa is having some paper mill machinery built in this country for his mill in Japan, whose product is book and news.

| External videos | |

|---|---|