Related Research Articles

Static electricity is an imbalance of electric charges within or on the surface of a material or between materials. The charge remains until it is able to move away by means of an electric current or electrical discharge. Static electricity is named in contrast with current electricity, where the electric charge flows through an electrical conductor or space, and transmits energy.

An inert gas is a gas that does not readily undergo chemical reactions with other chemical substances and therefore does not readily form chemical compounds. The noble gases often do not react with many substances and were historically referred to as the inert gases. Inert gases are used generally to avoid unwanted chemical reactions degrading a sample. These undesirable chemical reactions are often oxidation and hydrolysis reactions with the oxygen and moisture in air. The term inert gas is context-dependent because several of the noble gases can be made to react under certain conditions.

An inerting system decreases the probability of combustion of flammable materials stored in a confined space. The most common such system is a fuel tank containing a combustible liquid, such as gasoline, diesel fuel, aviation fuel, jet fuel, or rocket propellant. After being fully filled, and during use, there is a space above the fuel, called the ullage, that contains evaporated fuel mixed with air, which contains the oxygen necessary for combustion. Under the right conditions this mixture can ignite. An inerting system replaces the air with an inert gas, such as nitrogen, which can not support combustion.

Cryogenic fuels are fuels that require storage at extremely low temperatures in order to maintain them in a liquid state. These fuels are used in machinery that operates in space where ordinary fuel cannot be used, due to the very low temperatures often encountered in space, and the absence of an environment that supports combustion. Cryogenic fuels most often constitute liquefied gases such as liquid hydrogen.

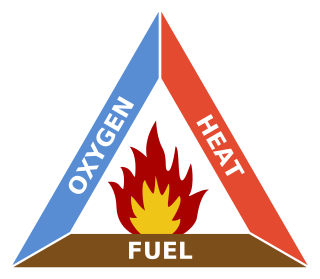

The fire triangle or combustion triangle is a simple model for understanding the necessary ingredients for most fires.

Fire control is the practice of reducing the heat output of a fire, reducing the area over which the fire exists, or suppressing or extinguishing the fire by depriving it of fuel, oxygen, or heat. Fire prevention and control is the prevention, detection, and extinguishment of fires, including such secondary activities as research into the causes of fire, education of the public about fire hazards, and the maintenance and improvement of fire-fighting equipment.

A flash fire is a sudden, intense fire caused by ignition of a mixture of air and a dispersed flammable substance such as a solid, flammable or combustible liquid, or a flammable gas. It is characterized by high temperature, short duration, and a rapidly moving flame front.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations could provide an ignition source, due to electrical arcing, or high temperature. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Mixtures of dispersed combustible materials and oxygen in the air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to as flammability limits or explosive limits. Combustion can range in violence from deflagration through detonation.

A kerosene heater, also known as a paraffin heater, is typically a portable, unvented, kerosene-fueled, space heating device. In Japan and other countries, they are a primary source of home heat. In the United States and Australia, they are a supplemental heat or a source of emergency heat during a power outage. Most kerosene heaters produce between 3.3 and 6.8 kilowatts.

A fire class is a system of categorizing fire with regard to the type of material and fuel for combustion. Class letters are often assigned to the different types of fire, but these differ between territories. There are separate standards for the United States, Europe, and Australia. This is used to determine the type of extinguishing agent that can be used for that fire class.

A combustible material is something that can burn in air. A combustible material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

Inert gas generator (IGG) refers to machinery on board marine product tankers. Inert gas generators consist distinctively of a gas producer and a scrubbing system.

Hydrogen safety covers the safe production, handling and use of hydrogen, particularly hydrogen gas fuel and liquid hydrogen.

The limiting oxygen concentration (LOC), also known as the minimum oxygen concentration (MOC), is defined as the limiting concentration of oxygen below which combustion is not possible, independent of the concentration of fuel. It is expressed in units of volume percent of oxygen. The LOC varies with pressure and temperature. It is also dependent on the type of inert (non-flammable) gas.

Gas blending is the process of mixing gases for a specific purpose where the composition of the resulting mixture is specified and controlled. A wide range of applications include scientific and industrial processes, food production and storage and breathing gases.

In June 1966, the British oil tanker MV Alva Cape caught fire twice in New York Harbor, first in a collision with tanker SS Texaco Massachusetts, and next while unloading cargo, and was subsequently scuttled offshore. Thirty-three people were killed in the collision, the resulting spill of its cargo of naphtha and major fire that ensued. Four more were killed about two weeks later while the emptied tanks were being inerted with carbon dioxide in a misguided attempt to make the damaged vessel safe for transport.

In fire and explosion prevention engineering, purging refers to the introduction of an inert purge gas into a closed system to prevent the formation of an ignitable atmosphere. Purging relies on the principle that a combustible gas is able to undergo combustion (explode) only if mixed with air in the right proportions. The flammability limits of the gas define those proportions, i.e. the ignitable range.

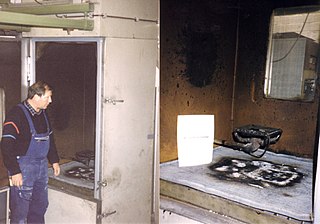

The devastating Bitburg tank explosion took place on 23 September 1954 at the then NATO air base near the city Bitburg, in the municipality of Niederstedem, Germany. The explosion took place in an underground storage tank containing JP-4, a military jet fuel blend. The toll was 34 dead, 2 injured, 3 missing. The explosion was caused by the deliberate activation of a novel carbon dioxide fire extinguishment system during an acceptance test as part of final commissioning. The JP-4 blend has since largely been abandoned due to safety concerns because of its low flash point.

References

- ↑ NFPA 69. Standard on Explosion Prevention Systems. National Fire Protection Association.

- 1 2 NFPA 77. Recommended Practice on Static Electricity. National Fire Protection Association.

- ↑ Hedlund, FH (2018). "Carbon dioxide not suitable for extinguishment of smouldering silo fires: static electricity may cause silo explosion" (PDF). Biomass and Bioenergy. Elsevier. 108: 113–119. doi:10.1016/j.biombioe.2017.11.009. S2CID 33522226.

- ↑ TRBS 2153. Vermeidung von Zündgefahren infolge elektrostatischer Aufladungen. [Prevention of electrostatic ignition sources.], Gemeinsame Minist. 15/16 (2009) 278.