Related Research Articles

An inert gas is a gas that does not form chemical reaction with another chemical substance and therefore does not form chemical compounds. The noble gases often do not react with many substances and were historically referred to as the inert gases. Inert gases are used generally to avoid unwanted chemical reactions degrading a sample. These undesirable chemical reactions are often oxidation and hydrolysis reactions with the oxygen and moisture in air. The term inert gas is context-dependent because several of the noble gases can be made to react under certain conditions.

A breathing gas is a mixture of gaseous chemical elements and compounds used for respiration. Air is the most common and only natural breathing gas, but other mixtures of gases, or pure oxygen, are also used in breathing equipment and enclosed habitats such as scuba equipment, surface supplied diving equipment, recompression chambers, high-altitude mountaineering, high-flying aircraft, submarines, space suits, spacecraft, medical life support and first aid equipment, and anaesthetic machines.

An inerting system decreases the probability of combustion of flammable materials stored in a confined space. The most common such system is a fuel tank containing a combustible liquid, such as gasoline, diesel fuel, aviation fuel, jet fuel, or rocket propellant. After being fully filled, and during use, there is a space above the fuel, called the ullage, that contains evaporated fuel mixed with air, which contains the oxygen necessary for combustion. Under the right conditions this mixture can ignite. An inerting system replaces the air with an inert gas, such as nitrogen, which can not support combustion.

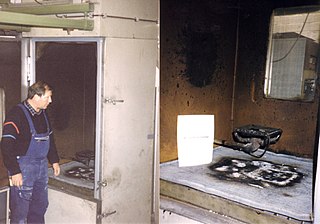

A flashover is the near-simultaneous ignition of most of the directly exposed combustible material in an enclosed area. When certain organic materials are heated, they undergo thermal decomposition and release flammable gases. Flashover occurs when the majority of the exposed surfaces in a space are heated to their autoignition temperature and emit flammable gases. Flashover normally occurs at 500 °C (932 °F) or 590 °C (1,100 °F) for ordinary combustibles and an incident heat flux at floor level of 20 kilowatts per square metre (2.5 hp/sq ft).

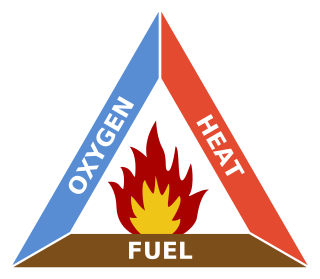

The fire triangle or combustion triangle is a simple model for understanding the necessary ingredients for most fires.

Fire control is the practice of reducing the heat output of a fire, reducing the area over which the fire exists, or suppressing or extinguishing the fire by depriving it of fuel, oxygen, or heat. Fire prevention and control is the prevention, detection, and extinguishment of fires, including such secondary activities as research into the causes of fire, education of the public about fire hazards, and the maintenance and improvement of fire-fighting equipment.

A flash fire is a sudden, intense fire caused by ignition of a mixture of air and a dispersed flammable substance such as a solid, flammable or combustible liquid, or a flammable gas. It is characterized by high temperature, short duration, and a rapidly moving flame front.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations could provide an ignition source, due to electrical arcing, or high temperature. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Mixtures of dispersed combustible materials and oxygen in the air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to as flammability limits or explosive limits. Combustion can range in violence from deflagration through detonation.

A fire class is a system of categorizing fire with regard to the type of material and fuel for combustion. Class letters are often assigned to the different types of fire, but these differ between territories. There are separate standards for the United States, Europe, and Australia. This is used to determine the type of extinguishing agent that can be used for that fire class.

A thermal oxidizer is a process unit for air pollution control in many chemical plants that decomposes hazardous gases at a high temperature and releases them into the atmosphere.

A combustible material is something that can burn in air. A combustible material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame.

Explosion protection is used to protect all sorts of buildings and civil engineering infrastructure against internal and external explosions or deflagrations. It was widely believed until recently that a building subject to an explosive attack had a chance to remain standing only if it possessed some extraordinary resistive capacity. This belief rested on the assumption that the specific impulse or the time integral of pressure, which is a dominant characteristic of the blast load, is fully beyond control.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

Hydrogen safety covers the safe production, handling and use of hydrogen, particularly hydrogen gas fuel and liquid hydrogen.

The limiting oxygen concentration (LOC), also known as the minimum oxygen concentration (MOC), is defined as the limiting concentration of oxygen below which combustion is not possible, independent of the concentration of fuel. It is expressed in units of volume percent of oxygen. The LOC varies with pressure and temperature. It is also dependent on the type of inert (non-flammable) gas.

Fire-safe polymers are polymers that are resistant to degradation at high temperatures. There is need for fire-resistant polymers in the construction of small, enclosed spaces such as skyscrapers, boats, and airplane cabins. In these tight spaces, ability to escape in the event of a fire is compromised, increasing fire risk. In fact, some studies report that about 20% of victims of airplane crashes are killed not by the crash itself but by ensuing fires. Fire-safe polymers also find application as adhesives in aerospace materials, insulation for electronics, and in military materials such as canvas tenting.

Oxygen compatibility is the issue of compatibility of materials for service in high concentrations of oxygen. It is a critical issue in space, aircraft, medical, underwater diving and industrial applications. Aspects include effects of increased oxygen concentration on the ignition and burning of materials and components exposed to these concentrations in service.

A spark extinguishing system is used for preventive fire protection. A spark extinguishing system can detect and eliminate ignition sources before a fire or dust explosion occurs. Systems for grinding, chopping, drying, cooling and pressing materials including their pneumatic or mechanical transport and extraction systems and facilities for separation or storage purposes, also dust collectors, filters, cyclones, silos, and hoppers are especially at risk.

In fire and explosion prevention engineering, inerting refers to the introduction of an inert (non-combustible) gas into a closed system to make a flammable atmosphere oxygen deficient and non-ignitable.

References

- 1 2 3 NFPA 56. Standard for Fire and Explosion Prevention During Cleaning and Purging of Flammable Gas Piping Systems. National Fire Protection Association

- 1 2 3 4 Hedlund, FH (2018). "Carbon dioxide not suitable for extinguishment of smouldering silo fires: static electricity may cause silo explosion" (PDF). Biomass and Bioenergy. Elsevier. 108: 113–119. doi:10.1016/j.biombioe.2017.11.009. S2CID 33522226.

- ↑ TRBS 2152 Teil 2 / TRGS 722. Vermeidung oder Einschränkung gefährlicher explosionsfähiger Atmosphäre. Technische Regeln für Betriebssicherheit. Ausgabe: März 2012 [Part 2: Prevention or reduction of explosive atmospheres]

- 1 2 3 Ashford, NA (1997). "Industrial safety: the neglected issue in industrial ecology". J Clean Prod. Elsevier. 5 (1–2): 115–21. doi:10.1016/S0959-6526(97)00024-3. hdl: 1721.1/115912 .