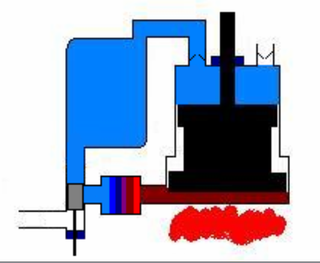

In an internal combustion engine, a turbocharger is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into the engine in order to produce more power for a given displacement.

A gas turbine or gas turbine engine is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

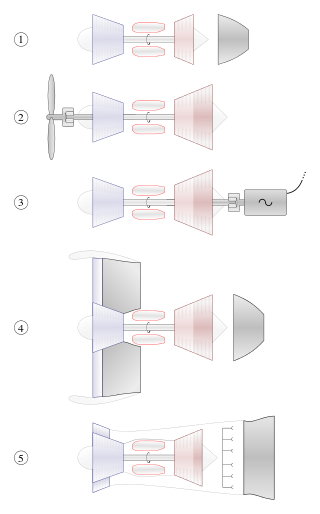

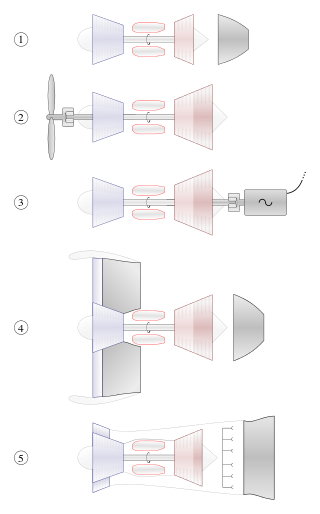

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

Nicolaus August Otto was a German engineer who successfully developed the compressed charge internal combustion engine which ran on petroleum gas and led to the modern internal combustion engine. The Association of German Engineers (VDI) created DIN standard 1940 which says "Otto Engine: internal combustion engine in which the ignition of the compressed fuel-air mixture is initiated by a timed spark", which has been applied to all engines of this type since.

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. It is characterized by isentropic compression and expansion, and isobaric heat addition and rejection, though practical engines have adiabatic rather than isentropic steps.

The Ericsson cycle is named after inventor John Ericsson who designed and built many unique heat engines based on various thermodynamic cycles. He is credited with inventing two unique heat engine cycles and developing practical engines based on these cycles. His first cycle is now known as the closed Brayton cycle, while his second cycle is what is now called the Ericsson cycle. Ericsson is one of the few who built open-cycle engines, but he also built closed-cycle ones.

William Hall Barnett is described as a 'founder' in his 1836 patent, and an 'ironfounder' in his 1838 patent, and later as an engineer and gas engineer, working in Brighton, UK. He worked for many years for the Brighton and Hove General Gas Company. He was born in Bradford and died in Brighton.

Samuel Brown was an English engineer and inventor credited with developing one of the earliest examples of an internal combustion engine, during the early 19th century.

A pneumatic motor, or compressed-air engine, is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed-air energy to mechanical work through either linear or rotary motion. Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied by either a vane type air motor, piston air motor, air turbine or gear type motor.

George Bailey Brayton (1830–1892) was an American mechanical engineer and inventor. He was noted for introducing the constant pressure engine that is the basis for the gas turbine, and which is now referred to as the Brayton cycle.

This timeline of heat engine technology describes how heat engines have been known since antiquity but have been made into increasingly useful devices since the 17th century as a better understanding of the processes involved was gained. A heat engine is any system that converts heat to mechanical energy, which can then be used to do mechanical work.They continue to be developed today.

Engine efficiency of thermal engines is the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work. There are two classifications of thermal engines-

- Internal combustion and

- External combustion engines.

Internal combustion engines date back to between the 10th and 13th centuries, when the first rocket engines were invented in China. Following the first commercial steam engine by Thomas Savery in 1698, various efforts were made during the 18th century to develop equivalent internal combustion engines. In 1791, the English inventor John Barber patented a gas turbine. In 1794, Thomas Mead patented a gas engine. Also in 1794, Robert Street patented an internal-combustion engine, which was also the first to use liquid fuel (petroleum) and built an engine around that time. In 1798, John Stevens designed the first American internal combustion engine. In 1807, French engineers Nicéphore and Claude Niépce ran a prototype internal combustion engine, using controlled dust explosions, the Pyréolophore. This engine powered a boat on the river in France. The same year, the Swiss engineer François Isaac de Rivaz built and patented a hydrogen and oxygen-powered internal-combustion engine. Fitted to a crude four-wheeled wagon, François Isaac de Rivaz first drove it 100 metres in 1813, thus making history as the first car-like vehicle known to have been powered by an internal-combustion engine.

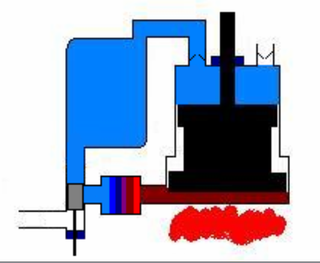

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

Alfred Büchi was a Swiss engineer and inventor. He was best known as the inventor of turbocharging. Büchi was born July 11, 1879, in Winterthur, Switzerland, growing up there and in Ludwigshafen. He was the son of Johann Büchi, a chief executive at Swiss industrial engineering and manufacturing firm Sulzer.

The Allam Cycle or Allam-Fetvedt Cycle is a process for converting carbonaceous fuels into thermal energy, while capturing the generated carbon dioxide and water.

A Velox boiler is a turbocharged, forced circulation, water-tube boiler which utilises an axial flow compressor and a gas turbine. Velox boilers, also known as Velox steam generators, were developed in the early 1930s by the Brown Boveri Company (BBC) of Switzerland. Velox boilers were the first commercially available machines to make use of axial compressors and played a pivotal role in the later development of BBC’s industrial gas turbines.

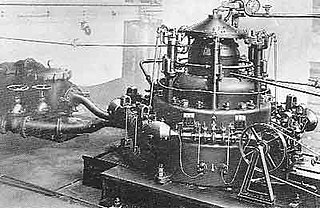

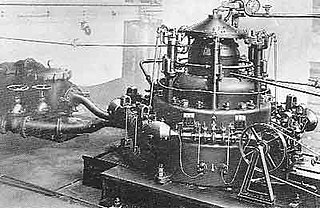

The Armengaud-Lemale gas turbine was an early experimental turbine engine built by the Société Anonyme des Turbomoteurs at their facility in Saint-Denis, Paris during 1906. The machine is named after the society's founders, Rene Armengaud and Charles Lemale.

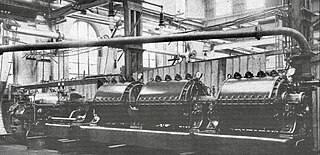

The Neuchâtel gas turbine is the world's first electric power-generating gas turbine to go into commercial operation. It was designed and constructed by Brown, Boveri & Cie and installed in 1939 at the municipal power station in Neuchâtel, Switzerland. The gas turbine was in service as a standby unit from 1940 until its retirement in 2002.

The Holzwarth gas turbine is a form of explosion, or constant volume, gas turbine where an air–fuel mixture is admitted, ignited and then exhausted from combustion chambers controlled by valves. The Holzwarth gas turbine is named after its developer Hans Holzwarth (1877–1953) who designed several prototype engines used for testing and experimental service in Germany and Switzerland between 1908 and 1943.